Upflow cyclic reoxygenation machine and sewage treatment process using the upflow reoxygenation machine

A kind of reoxygenation machine and body technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, aerobic process treatment, etc., can solve the problem of high energy consumption, achieve inhibition of anaerobic reaction, reduce energy Consumption, increase the effect of dissolved oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

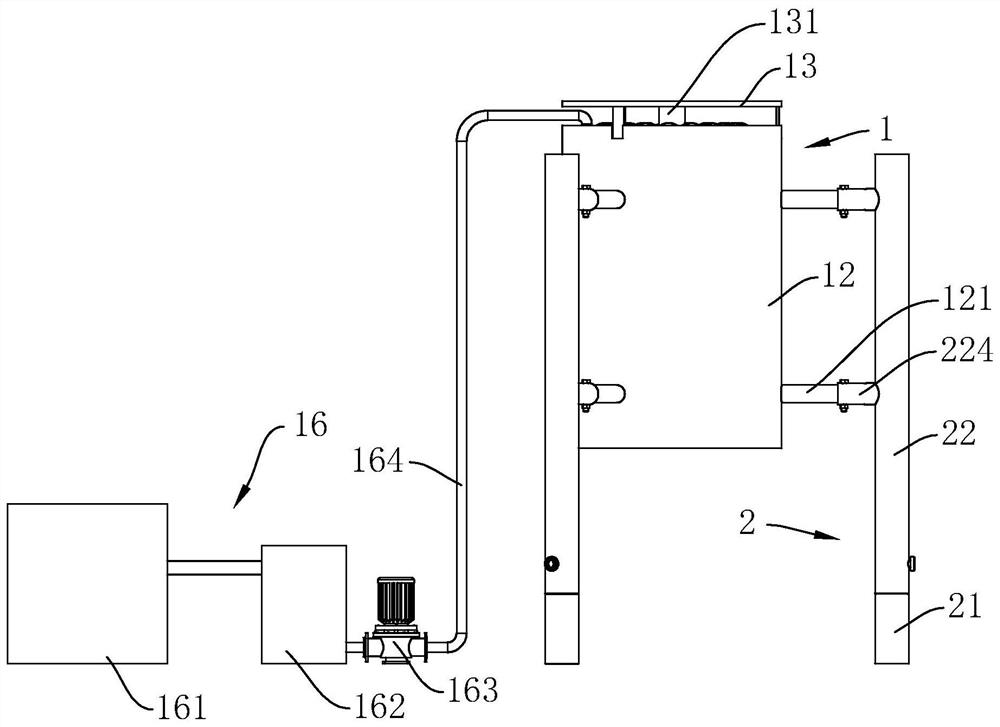

[0046] see figure 1 , an upflow cycle reoxygenation machine, including a base 2 fixed at the bottom of a river and a body 1 slidably connected to the base 2 .

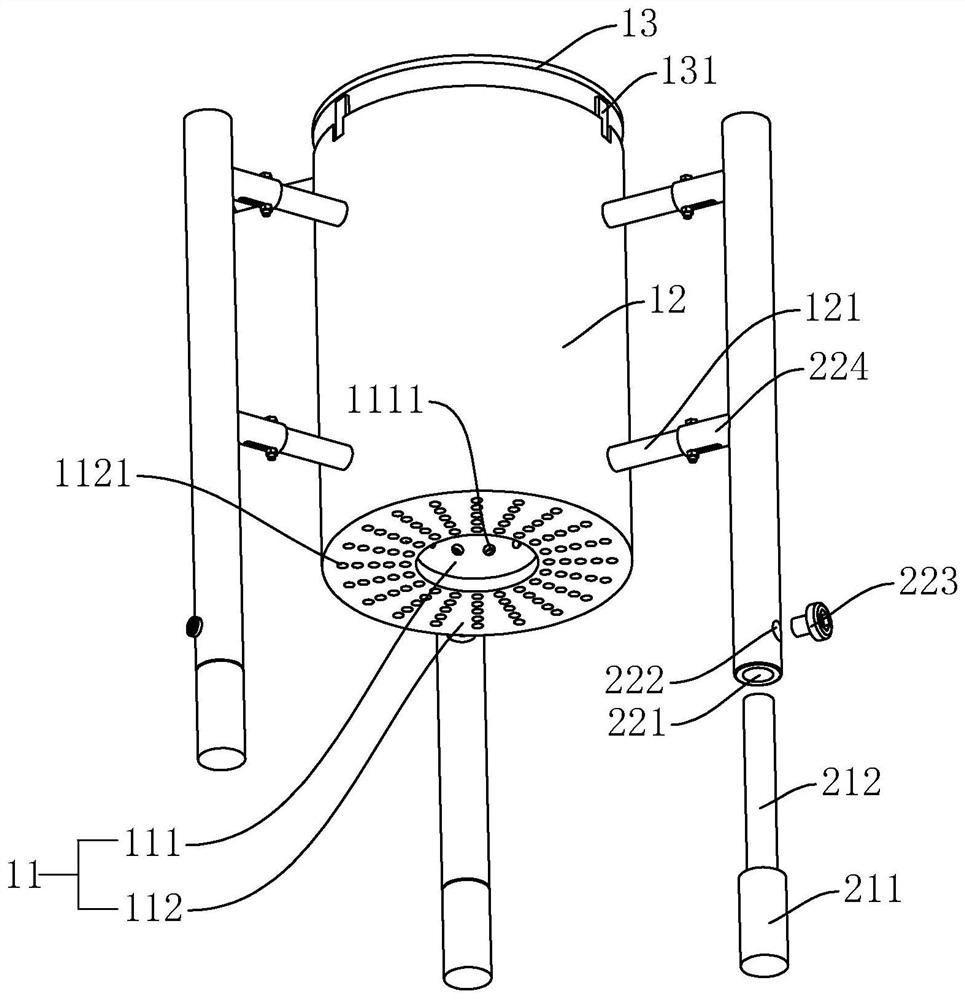

[0047] see figure and figure 2 , the base 2 includes a fixed frame 21 and a sliding frame 22 slidably connected to the fixed frame 21 for connecting the body 1 . The fixed frame 21 includes a fixed seat 211 supported on the bottom of the river and a connecting rod 212 passing through the sliding frame 22 . The sliding frame 22 is provided with a sliding cavity 221 for the connecting rod 212 to slip through and a positioning cavity 222 vertically connected to the sliding cavity 221. The fastening bolt 223 , the end of the fastening bolt 223 abuts against the connecting rod 212 . The sliding frame 22 is also provided with a positioning column 224 for connecting the machine body 1 .

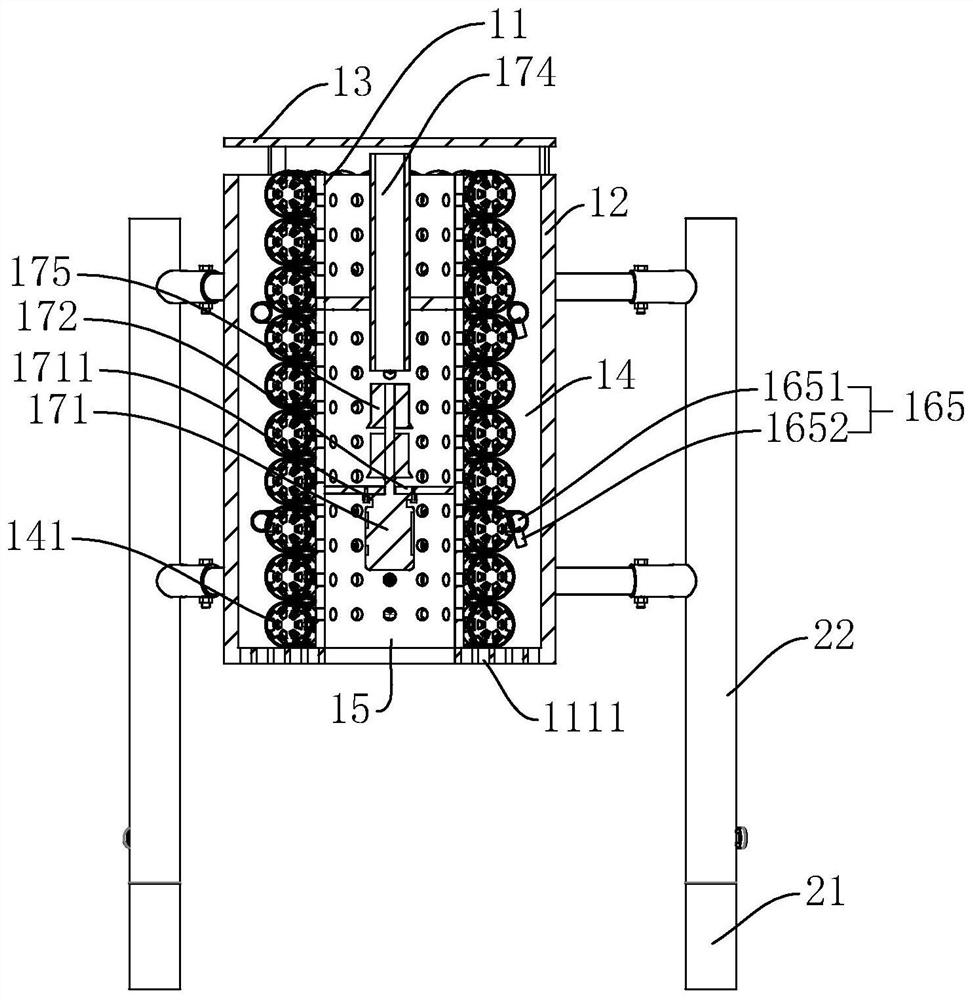

[0048] see figure 2 and image 3 , the body 1 is cylindrical as a whole, and includes an inner body 11 coaxially arranged, an outer...

Embodiment 2

[0059] A sewage treatment process utilizing an upflow recirculation re-aerator, comprising the following steps:

[0060] Step1, fix the upflow re-aeration machine at the bottom of the river, and make one of the openings of the suction pipe above the liquid level;

[0061] Step2, start the driving motor, so that the driving motor drives the centrifugal impeller to rotate to generate negative pressure at the other opening of the suction pipe, and push the water at the bottom of the river away from the bottom of the river;

[0062] Step3, the suction pipe pumps the air to the centrifugal impeller, the gas mixes with the water body at the blade of the centrifugal impeller to form a large number of bubbles, and the bubbles are broken several times under the mechanical cutting of the impeller to form a gas-liquid mixture;

[0063] Step4, the gas-liquid mixture passes through the inner body and diffuses to the outer chamber under the push of the centrifugal impeller;

[0064] Step5,...

Embodiment 3

[0067] The sewage treatment process of embodiment 3 is roughly the same as that of embodiment 2, and the difference is that the surface of the biological filler used in embodiment 3 is pre-loaded with deodorizing microorganisms, and the loading method of deodorizing microorganisms is as follows:

[0068] Step1.1, add 20g of glucose, 20g of peptone, 8g of yeast extract, 4g of potassium dihydrogen phosphate, 4g of dipotassium hydrogen phosphate, and 0.04g of magnesium sulfate into a culture tank with a maximum capacity of 4L. Add water into the culture tank to make up until the inner volume of the culture tank reaches 4L and stir evenly to obtain the microbial nutrient solution;

[0069] Step1.2, add the biological filler into the culture tank, and submerge the microbial nutrient solution into the culture tank for 8 hours;

[0070] Step1.3, intermittently pass sulfur-containing gas into the microbial nutrient solution, the ventilation rate is 1L / min, every 30min, and continue to v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com