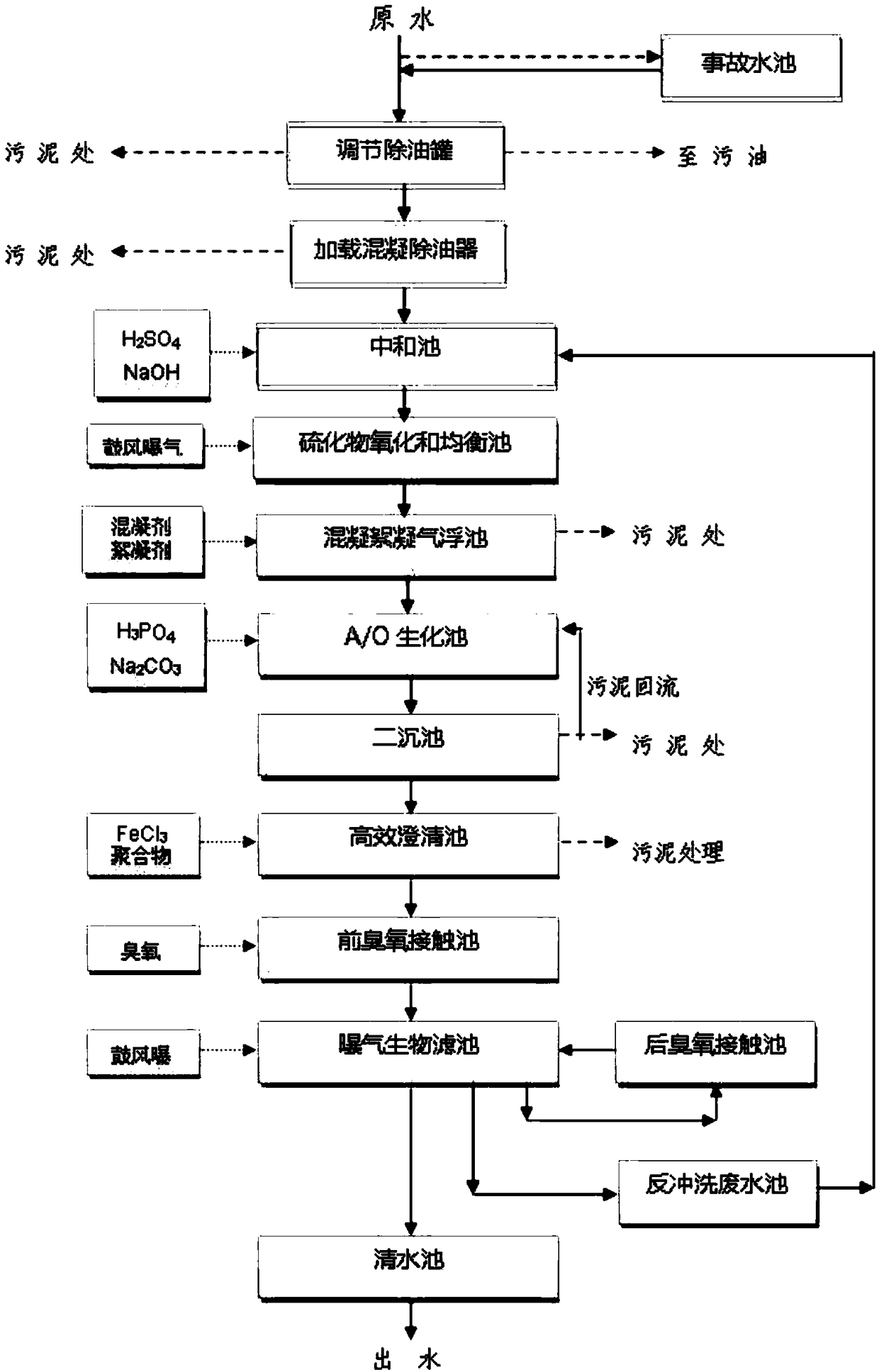

Asphalt production wastewater treatment process

A technology for the production of waste water and treatment process, applied in the direction of biological water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., which can solve the hidden dangers of the ecological environment, low removal rate of SS and COD, and sewage not reaching the second level of sewage discharge Level standards and other issues, to achieve high oil removal rate, low suspended solids in effluent, and reduce the effect of ozone dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The asphalt production wastewater treatment process of the present embodiment is carried out according to the following steps:

[0039] (1) Asphalt production wastewater is collected into the wastewater treatment system through the pipe network in the factory area, and firstly lifted into the regulating degreasing tank to remove the slick oil and floating mud in the wastewater; wastewater water quality: oil content 300-1200mg / L, SS300-500mg / L , Volatile phenol 50~100mg / L;

[0040] (2) After adjusting the water out of the oil removal tank, it flows into the loading coagulation degreaser to further remove free insoluble oil;

[0041] (3) Load the effluent of the coagulation degreaser into the neutralization tank, adjust the pH according to the raw water quality, and then enter the balance tank to adjust the water quality and water quantity of the wastewater, and remove sulfide;

[0042] (4) The wastewater from the balance tank passes through the coagulation, flocculation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com