A kind of residual activated sludge drying treatment process

A technology of residual activity and treatment process, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of limited drying efficiency and achieve rapid dehydration, Effect of improving dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

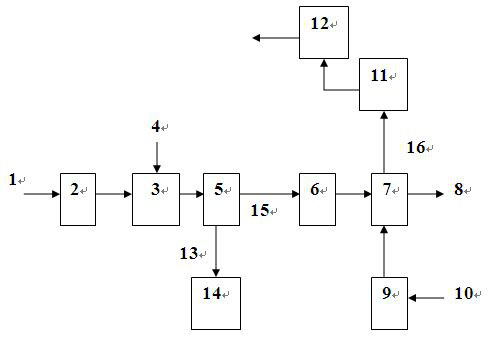

Method used

Image

Examples

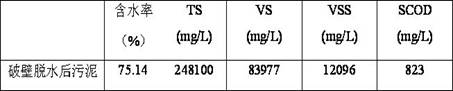

Embodiment 2

[0030] It is basically the same as Example 1, except that the treatment agent is polyether-modified trisiloxane of 1% TS sludge and the concentration of 0.1% TS sludge is 15% ethylenediaminetetraacetic acid, and adding 0.2% The properties of polyoxin and nikkomycin in TS sludge are shown in Table 2 after wall-breaking and dehydration, and the moisture content of the remaining sludge after final drying dropped to 10.2%.

[0031] Table 2 Analysis table of sludge properties

[0032]

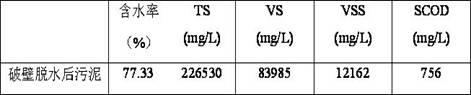

Embodiment 3

[0034] It is basically the same as that of Example 1, except that the inlet temperature of the solar multi-layer mesh belt type low-temperature drying box, the amount of carrier gas and the residence time in the box are adjusted. After dehydration, the mud cake enters the filter press to be pressed into 3mm strips. The sludge enters the solar multi-layer mesh belt low-temperature drying box through the conveyor belt. The carrier gas is heated to 70°C by the solar tube, the humidity in the box is 5%, and the carrier gas volume is 800m 3 / h, the sludge stays in the tank for 4 hours, and the moisture content of the sludge drops to 12.7% after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com