Preparation method of heat-resistant migration-resistant environment-friendly polyether plasticizer

An environmentally-friendly polyester and migration-resistant technology, which is applied in the synthesis of fine chemicals and the application of plastic additives, can solve the problems of PVC matrix softness reduction, poisoning, etc., and achieve the effect of medium viscosity, low color and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The reaction scheme is as follows:

[0021]

[0022] Add 49.75g (0.345mol) of 1,4-cyclohexanedimethanol, 39.63g (0.30mol) of glutaric acid, 33.24g (0.21mol) of 2-propylheptanol, 0.6g (0.001mol) of tetra-n-butyl titanate as a catalyst, and 10mL of cyclohexane as a water-carrying agent, heated to 205 ° C, refluxed for 7 hours until the acid value Then reduce the reaction product under the condition of -0.1MPa, and remove the unreacted 1,4-cyclohexanedimethanol and the end-capping agent 2-propylheptanol by vacuum distillation to recover and utilize the obtained substrate It is a refined polyester plasticizer product.

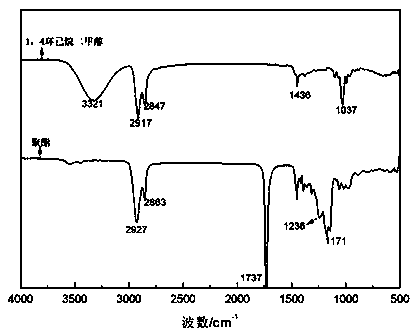

[0023] figure 1 It can be seen that there are still differences in the infrared spectrum of the raw material and the product. In the infrared spectrum of 1,4-cyclohexanedimethanol, it can be seen that at 3321cm -1 is the stretching vibration peak of -OH at 2917cm -1 and 2847cm -1 is the symmetrical and asymmetric stretching vibration peak of -C-H, at...

Embodiment 2

[0028] A preparation method of a heat-resistant, migration-resistant and environmentally friendly polyester plasticizer, using glutaric acid, 1,4-cyclohexanedimethanol and 2-propylheptanol as main raw materials, and obtaining polyester-type plasticizers through esterification and polycondensation Environmentally friendly plasticizer, the specific steps are as follows:

[0029] (1) Esterification and polycondensation reaction: Add the reactants glutaric acid, 1,4-cyclohexanedimethanol and 2-propylheptanol into the reactor, and then add the catalyst, water-carrying agent and end-capping agent;

[0030] The alkyd molar ratio of 1,4-cyclohexanedimethanol to glutaric acid is 1:1, the molar ratio of the amount of capping agent 2-propylheptanol to glutaric acid is 0.4:1, and the mass of the catalyst It is 0.3% of the total mass of alkyd, and the consumption of water-carrying agent is 5% of the total mass of reactants;

[0031] Stir and heat the above raw materials to 140°C within 10...

Embodiment 3

[0037] A preparation method of a heat-resistant, migration-resistant and environmentally friendly polyester plasticizer, using glutaric acid, 1,4-cyclohexanedimethanol and 2-propylheptanol as main raw materials, and obtaining polyester-type plasticizers through esterification and polycondensation Environmentally friendly plasticizer, the specific steps are as follows:

[0038] (1) Esterification and polycondensation reaction: Add the reactants glutaric acid, 1,4-cyclohexanedimethanol and 2-propylheptanol into the reactor, and then add the catalyst, water-carrying agent and end-capping agent;

[0039]The alkyd molar ratio of 1,4-cyclohexanedimethanol to glutaric acid is 1.2:1, the molar ratio of the amount of capping agent 2-propylheptanol to glutaric acid is 0.9:1, and the mass of the catalyst It is 0.7% of the total mass of alkyd, and the consumption of water-carrying agent is 15% of the total mass of reactants;

[0040] Stir and heat the above raw materials to 150°C within ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com