Water-based nano-silver electrically-conductive printing ink capable of sintering at room temperature as well as preparation and application thereof

A technology of conductive ink and nano-silver, applied in the direction of ink, application, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

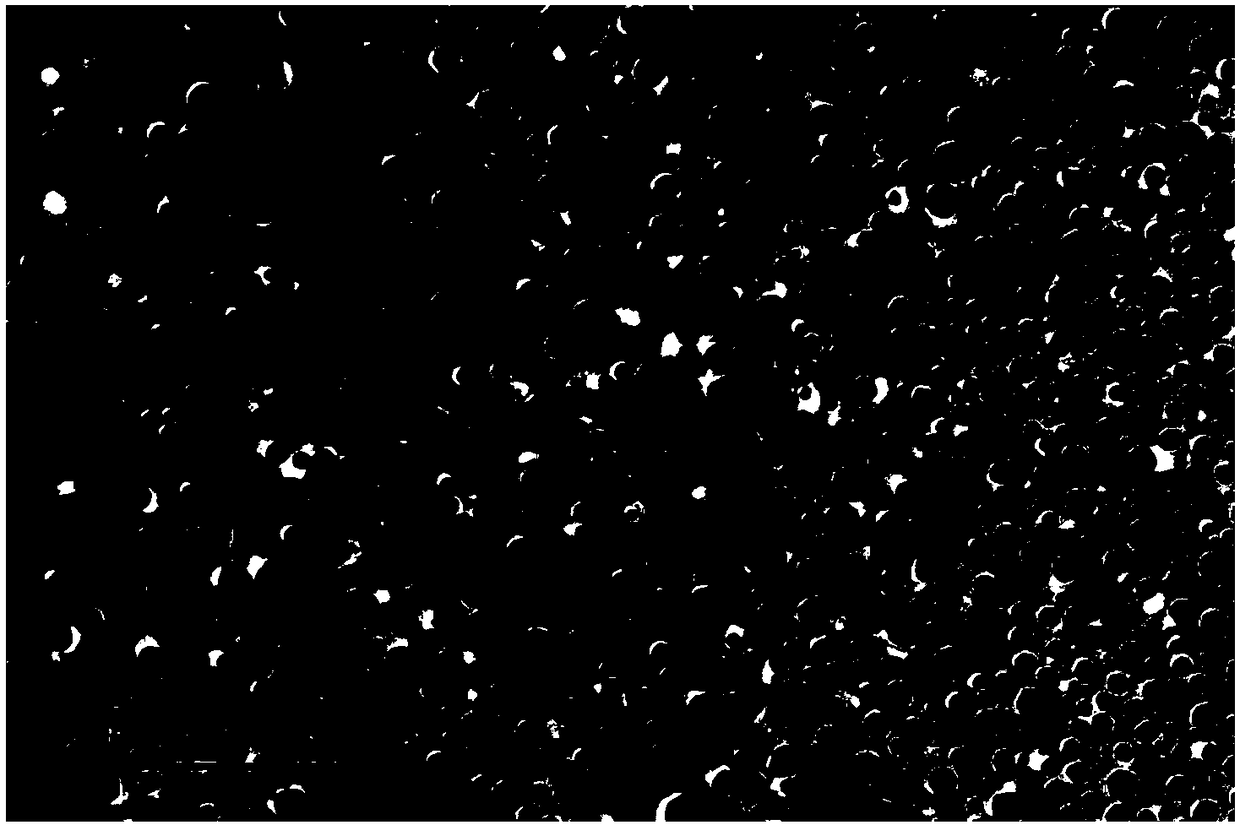

[0032] Preparation of nano-silver particles dispersed with a short-chain molecular dispersant: configure a total of 70ml of ferrous sulfate solution with a concentration of 250g / L and a sodium citrate dihydrate solution with a concentration of 400g / L, and stir evenly to form a reducing solution; Concentration is 25ml of silver nitrate solution of 75g / L, and described reducing solution is added in the silver nitrate solution drop by drop at the rate of 10ml / min, while adding dropwise reducing solution, the reaction solution is mechanically stirred with the rotating speed of 150r / min , after the dropwise reaction was completed for 30 minutes, the obtained reaction system was centrifuged with a centrifuge, and then repeatedly centrifuged and washed 4 times with deionized water to obtain nano-silver particles dispersed with a short-chain molecular dispersant, such as figure 1 As shown, the particle size range of the nano-silver particles is 2-25nm, and the dispersion in deionized w...

Embodiment 2

[0044] Preparation of nano-silver particles dispersed with a short-chain molecular dispersant: configure a total of 70ml of a ferrous sulfate solution with a concentration of 250g / L and a sodium citrate dihydrate solution with a concentration of 400g / L, and stir evenly to form a reducing solution. Concentration is 25ml of silver nitrate solution of 75g / L, and described reducing solution is added in the silver nitrate solution drop by drop at the rate of 10ml / min, while adding dropwise reducing solution, the reaction solution is mechanically stirred with the rotating speed of 150r / min , after the dropwise addition finished reaction 30min, the obtained reaction system was centrifuged with a centrifuge, and then repeatedly centrifuged and washed 4 times with deionized water to obtain silver nanoparticles dispersed with a short-chain molecular dispersant. The particle size range of the silver nanoparticles is 2‐25nm, excellent dispersion in deionized water, all nanoparticles are ev...

Embodiment 3

[0049] Preparation of nano-silver particles dispersed with a short-chain molecular dispersant: configure a total of 70ml of a ferrous sulfate solution with a concentration of 250g / L and a sodium citrate dihydrate solution with a concentration of 400g / L, and stir evenly to form a reducing solution. Concentration is 25ml of silver nitrate solution of 75g / L, and described reducing solution is added in the silver nitrate solution drop by drop at the rate of 10ml / min, while adding dropwise reducing solution, the reaction solution is mechanically stirred with the rotating speed of 150r / min , after the dropwise addition finished reaction 30min, the obtained reaction system was centrifuged with a centrifuge, and then repeatedly centrifuged and washed 4 times with deionized water to obtain silver nanoparticles dispersed with a short-chain molecular dispersant. The particle size range of the silver nanoparticles is 2‐25nm, excellent dispersion in deionized water, all nanoparticles are ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com