Organic fuel cell anti-freeze cooling liquid with low conductivity and ultra-long acting and preparation method of anti-freeze cooling liquid

An antifreeze coolant and fuel cell technology, applied in fuel cells, chemical instruments and methods, circuits, etc., can solve the problems of long delivery cycle, lower boiling point, high price, etc., achieve efficient heat dissipation, suppress acidification, and low conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

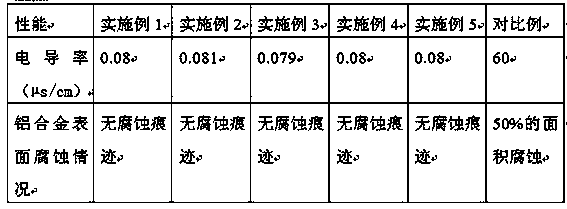

Embodiment 1

[0017] The low-conductivity ultra-long-acting organic fuel cell antifreeze coolant of the present embodiment has the following composition and content: ethylene glycol is 10wt%, 8-hydroxyquinoline is 0.001wt%, and uracil is 0.02wt%, 0.01wt% of 4-acetaminophen, 0.05wt% of benzyl triazole, octadecylamine, 0.05wt% of N-bromosuccinimide, 0.001wt% of inosine, balance It is deionized water; the sum of the percentages of the components of the antifreeze coolant is 100%.

[0018] The pH value of the antifreeze coolant is 7.5 and the conductivity is 0.08µs / cm.

[0019] The manufacturing method of the low-conductivity ultra-long-acting organic fuel cell antifreeze coolant of the present embodiment includes the following steps: putting the above components of the antifreeze coolant into a reaction kettle, and first adding ethylene glycol and deionized water to the reactor. Water was put into the reactor, stirred for 5min at room temperature, and then 8-hydroxyquinoline, uracil, 4-acetam...

Embodiment 2

[0023] The low-conductivity ultra-long-acting organic fuel cell antifreeze coolant of the present embodiment has the following composition and content: ethylene glycol is 70 wt %, 8-hydroxyquinoline is 0.01 wt %, and uracil is 0.005wt%, 0.03wt% of 4-acetaminophen, 0.01wt% of benzyl triazole, octadecylamine, 0.005wt% of N-bromosuccinimide, 0.01wt% of inosine, balance It is deionized water; the sum of the percentages of the components of the antifreeze coolant is 100%.

[0024] The pH value of the antifreeze coolant is 7.4 and the conductivity is 0.081µs / cm.

[0025]The manufacturing method of the low-conductivity ultra-long-acting organic fuel cell antifreeze coolant of the present embodiment includes the following steps: putting the above components of the antifreeze coolant into a reaction kettle, and first adding ethylene glycol and deionized water to the reactor. Water was put into the reaction kettle, stirred at room temperature for 3min, and then 8-hydroxyquinoline, urac...

Embodiment 3

[0029] The low-conductivity ultra-long-acting organic fuel cell antifreeze cooling liquid of the present embodiment, the composition and content of the antifreeze cooling liquid are: ethylene glycol is 40wt%, 8-hydroxyquinoline is 0.005wt%, and uracil is 0.012wt%, 0.02wt% of 4-acetaminophen, 0.03wt% of benzyl triazole, octadecylamine, 0.025wt% of N-bromosuccinimide, 0.005wt% of inosine, balance It is deionized water; the sum of the percentages of the components of the antifreeze coolant is 100%.

[0030] The pH value of the antifreeze coolant is 7.6 and the conductivity is 0.079µs / cm.

[0031] The manufacturing method of the low-conductivity ultra-long-acting organic fuel cell antifreeze coolant of the present embodiment includes the following steps: putting the above components of the antifreeze coolant into a reaction kettle, and first adding ethylene glycol and deionized water to the reactor. Water was put into the reaction kettle, stirred at room temperature for 8min, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com