Photosensitive resin composition and water washing resin plate

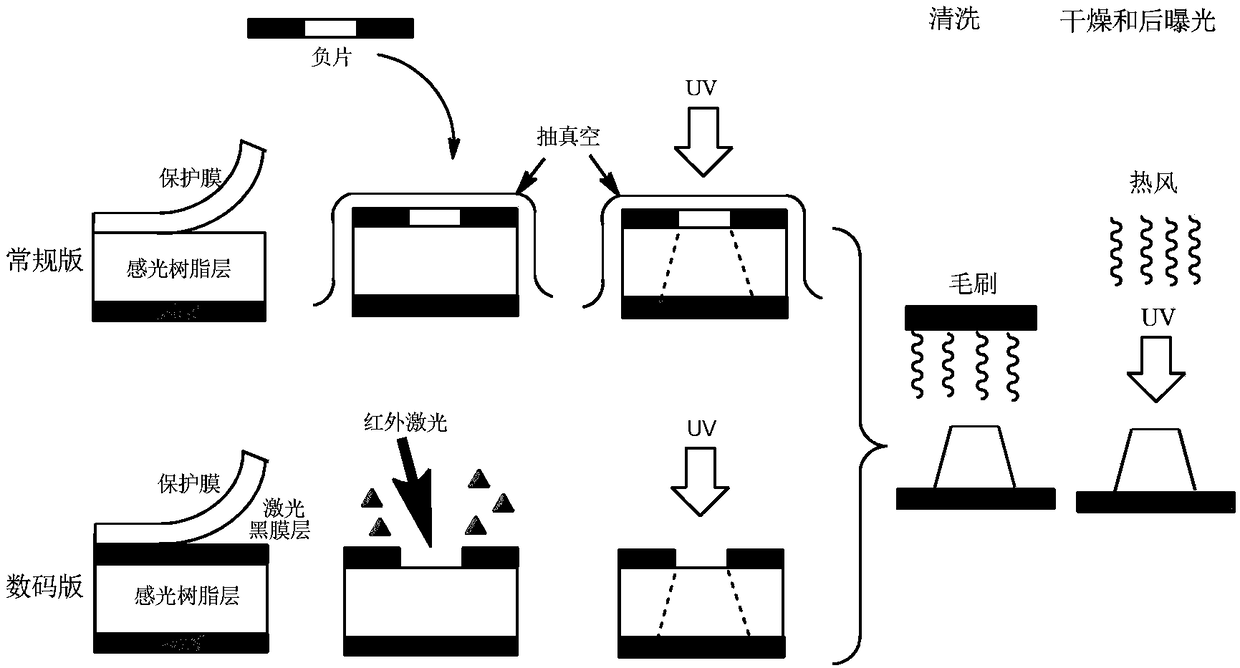

A resin composition and photosensitive resin technology, applied in the field of photosensitive resin composition and water-washed resin plate, can solve the problems of increasing process complexity, tacky surface, large volume shrinkage rate, etc., and achieve imaging sharpness and graphic definition Improve, high hardness and wear resistance, overcome the effect of oxygen inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] The present invention will be described in detail below through examples. Unless otherwise specified, the parts described in the examples refer to parts by weight.

Synthetic example 1

[0051] P1 (3-mercaptopropionic acid modified polyvinyl acetate resin)

[0052] In a 250ml four-necked bottle equipped with a stirrer, condenser, constant pressure titration funnel, and thermometer, add 20 parts of PVA resin NK-05 (Nippon Synthetic Chemical Industry Co., Ltd., polymerization degree 500, saponification degree 71~75mol%), 100 parts of N,N-dimethylformamide (DMF), heated to 100°C, 3 parts of 3-mercaptopropionic acid, 0.1 part of p-toluenesulfonic acid, 5 parts of DMF were added dropwise, reacted for 2 hours, and then carried out with 300 parts of acetone Precipitate to obtain mercapto-modified PVA resin. The polymer is soluble in water at 25°C.

[0053] P2 (3-mercaptoisobutyric acid modified polyvinyl acetate resin)

[0054] Except that the thiol compound was replaced with 3-mercaptoisobutyric acid, the procedure was carried out exactly the same as in P1. The polymer is soluble in water at 25°C.

[0055] P3 (KH580 modified polyvinyl acetate resin)

[0056] In...

Embodiment 1

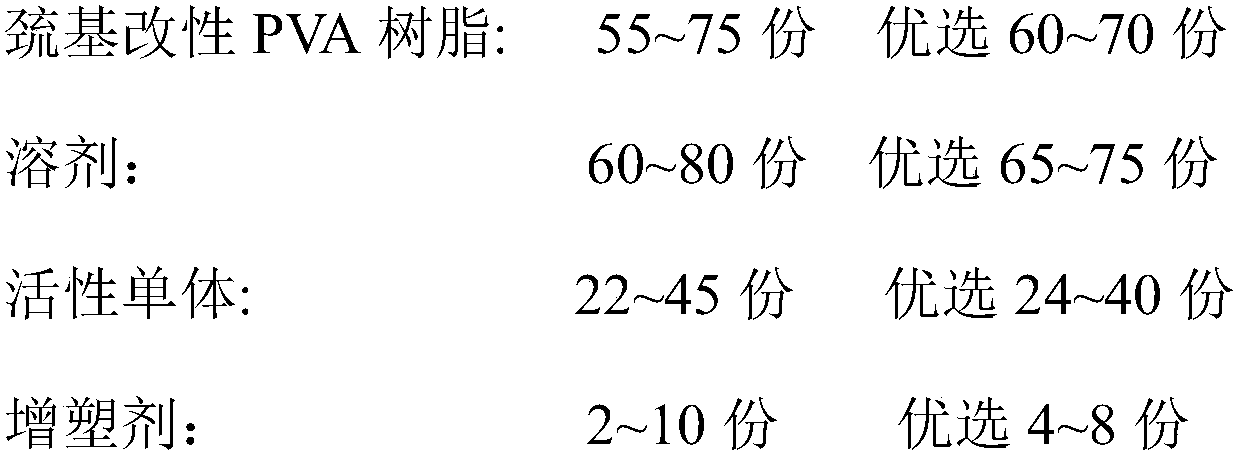

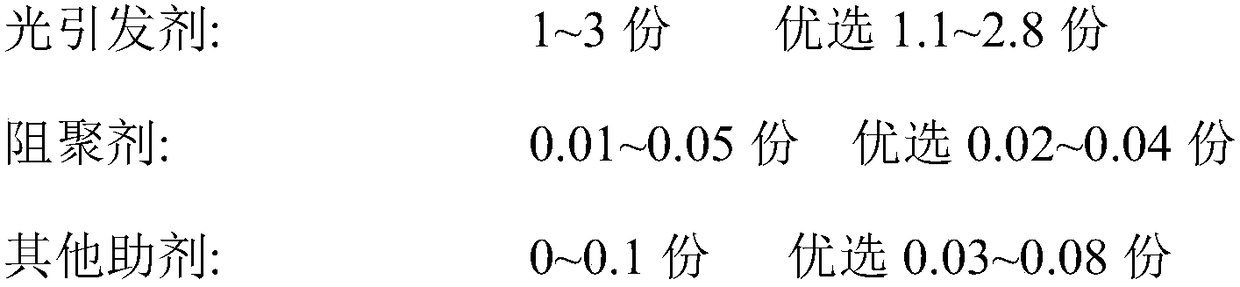

[0060] The above-mentioned synthetic mercapto-modified polyvinyl acetate resin is added to the formula of the photosensitive resin layer, as shown in the following table:

[0061]

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com