Electrochemistry-based micro-component reliable and nondestructive operation

A micro-component, electrochemical technology, applied in chemical process analysis/design, electrical digital data processing, design optimization/simulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

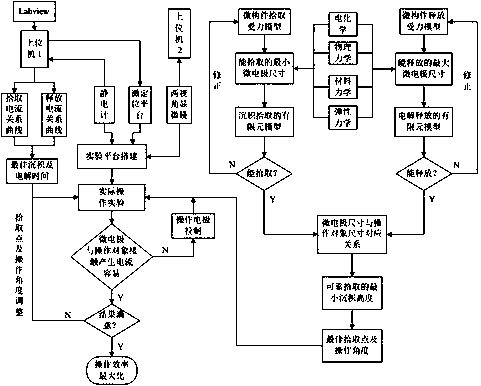

[0016] First, the electrochemical theory and the force between the operating object and the substrate are studied, and the analysis demonstrates that by depositing metal ions in the salt solution in the microelectrode, forming a firm micro-metal column in the operating electrode that is completely combined with the operating object to overcome the problem The feasibility of operating the force between the object and the substrate; and the feasibility of accurate and non-destructive release of the micro metal pillars formed during the electrolytic pick-up process, and the feasibility of the method is verified through actual operation. On this basis, an accurate force model for electrochemical pick-up and release is established. Based on this model and related theories of physical mechanics, material mechanics, and elastic mechanics, the relationship between the size of the micro-component and the size of the micro-electrode required for pick-up and release is obtained. Correspon...

specific Embodiment 2

[0018] If the operation point is not selected properly when picking up, it is easy to cause slippage, resulting in failure of operation and easy damage to the operation electrode. But not only the middle point of the component is the best operation point, it can also pick up the operation object well, and it may also make the release easier (because one end of the operation object touches the operation base first), so it needs to be based on the established The mechanical model of pick-up and release is established, the finite element model of deposition pick-up and electrolytic release is established, and the simulation analysis is carried out. The established force model is further revised according to theoretical analysis theory and simulation simulation, so as to find out the force model under reliable and non-destructive conditions. Optimum operating angle, operating point, and the shape of the most favorable microelectrode, based on the simulation results, the microelectr...

specific Embodiment 3

[0020] Since the deposition through the salt solution is greatly affected by the humidity, temperature, solution concentration and applied voltage, once the operating conditions are not satisfied, it is easy to cause precipitation. Once there is salt precipitation, it will lead to the failure of the release, so In actual operation, it is first necessary to find out the parameters that have no salt precipitation and can be deposited at a faster speed based on theoretical analysis and actual operation. In addition, the proper height of micro-metal deposition is related to the reliable pick-up of micro-components and the efficiency of manipulation. Therefore, according to the reasonable shape and size of the drawn microelectrode, through the established operation mechanics model, calculate the minimum height of the micro metal column required for reliable pickup and deposition, and then communicate with the electrometer through the Labview host computer program to obtain the depos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com