Ceramic-based dental department bone powder and preparation method thereof

A technology based on dental and bone powder, applied in the field of ceramic-based dental bone powder and its preparation, can solve the problems of poor hydrophilicity, unfavorable cell adhesion and proliferation, and poor biocompatibility, so as to improve water absorption performance, improve bone repair effect, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

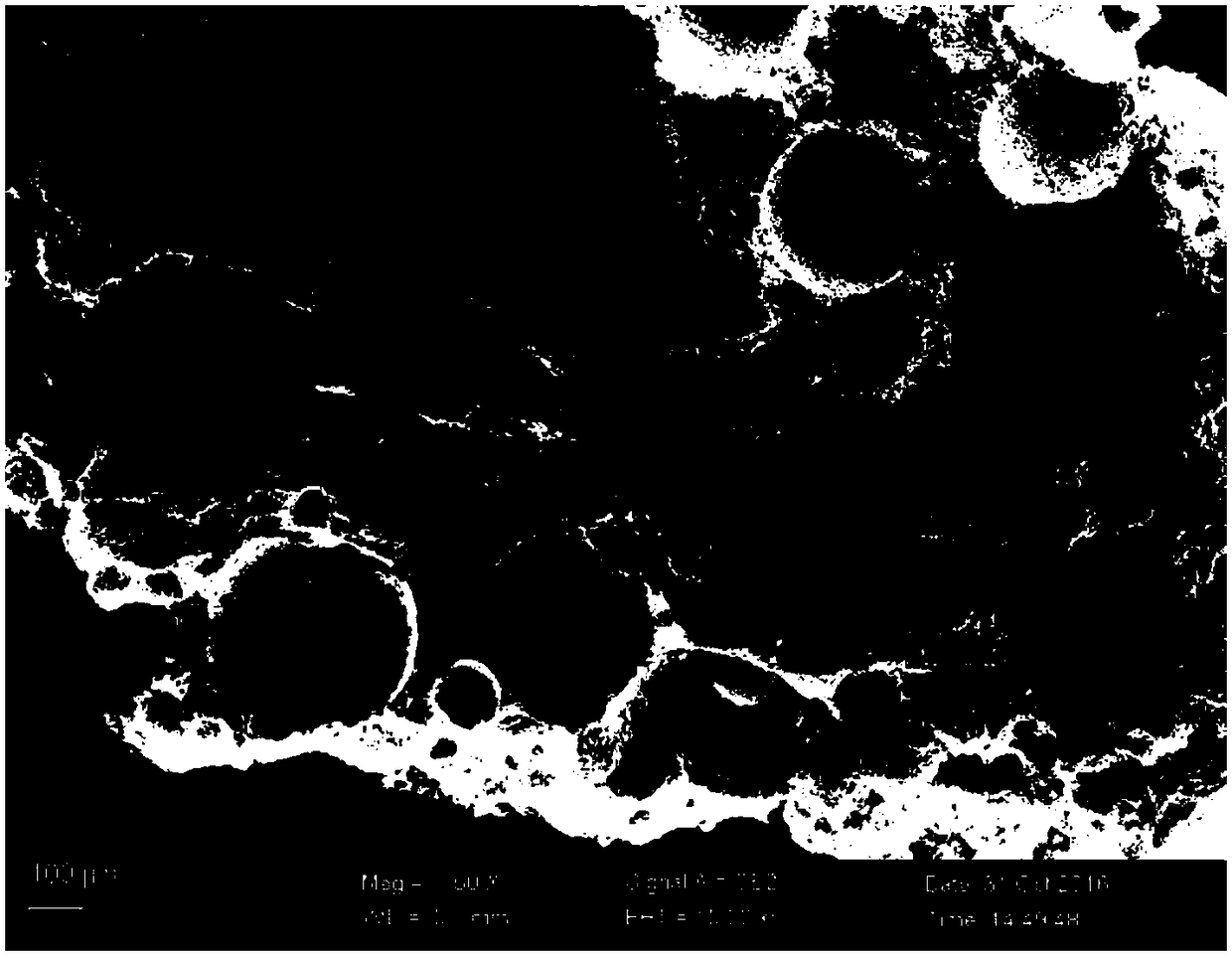

[0079] In some embodiments, the preparation method of the porous hydroxyapatite includes:

[0080] (a) preparing hydroxyapatite suspension;

[0081] (b) adding the first PMMA particles and the second PMMA particles to the hydroxyapatite suspension to obtain a sintered base liquid;

[0082] (c) placing the sintering base liquid in a sintering device for sintering to obtain a sintered material;

[0083] (d) crushing and sieving the sintered material to obtain the porous hydroxyapatite.

[0084] Preferably, the step (a) is carried out as follows:

[0085] Mix 15-20g of hydroxyapatite in batches (for example, the hydroxyapatite can be divided into 3-10 parts, so that the hydroxyapatite can be added in 3-10 times) and 20-35mL of PBS solution are mixed, Then add 1.5-2.5 mL of polyvinyl alcohol solution with a concentration of 0.05-0.1 g / mL, stir evenly, and prepare the hydroxyapatite suspension. The PBS solution here is a commonly used phosphate buffered saline solution with a p...

Embodiment 1

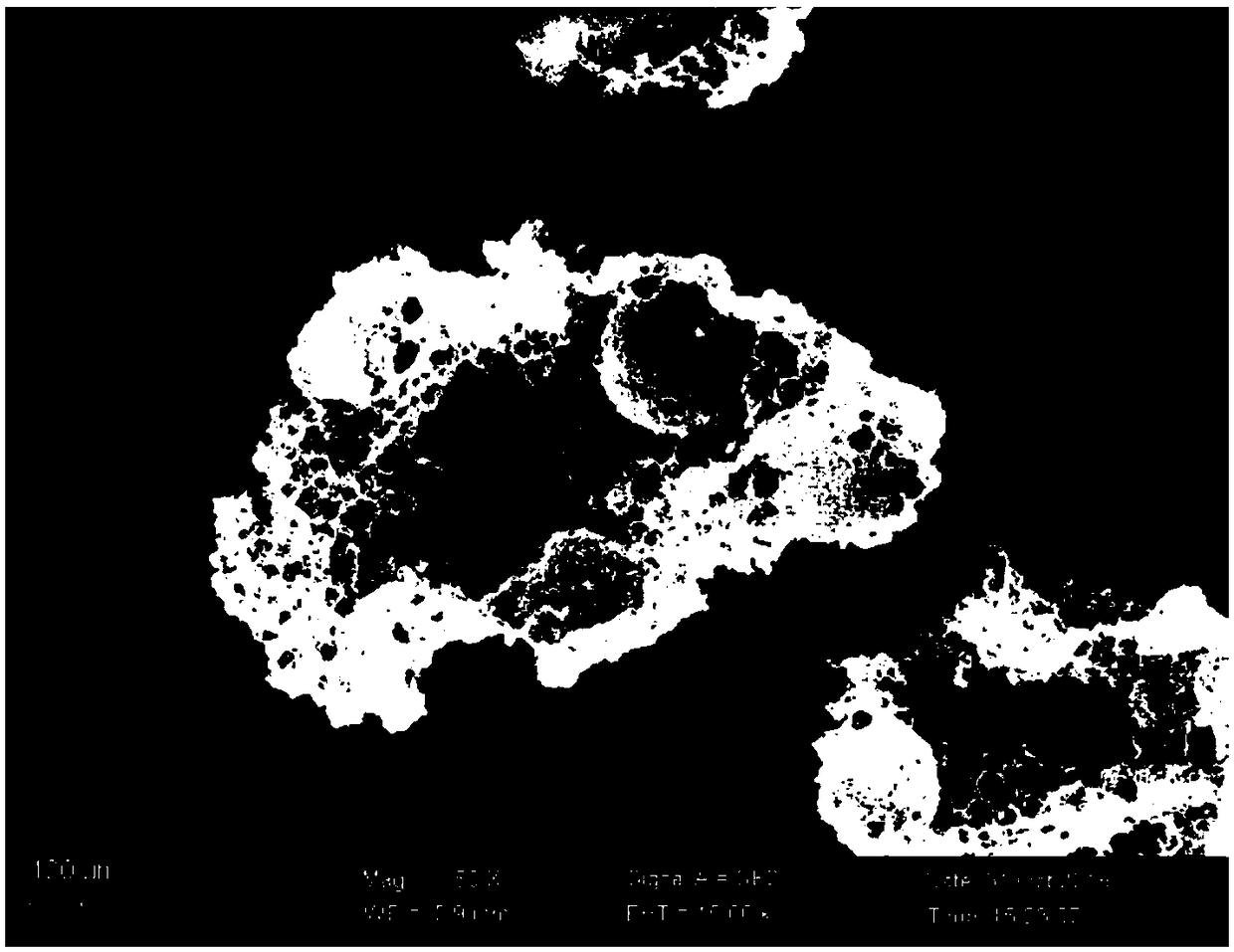

[0116] A kind of ceramic base dental bone powder, its preparation component comprises:

[0117] Porous hydroxyapatite;

[0118] Type I collagen, the mass is 1% of the mass of porous hydroxyapatite;

[0119] Wherein, the preparation component of porous hydroxyapatite comprises hydroxyapatite, the first PMMA particle and the second PMMA particle, the mass ratio is 5:2.5:1.5, and the particle diameter of the first PMMA particle is 50 μ m, the second PMMA particle The particle size of the particles is 500 μm; and

[0120] Porous hydroxyapatite is prepared by sintering, and the sintering process is shown in Table 1

[0121] Table 1

[0122]

Embodiment 2

[0124] A kind of ceramic base dental bone powder, its preparation component comprises:

[0125] Porous hydroxyapatite;

[0126] Type I collagen, the mass is 10% of the mass of porous hydroxyapatite;

[0127]Wherein, the preparation component of porous hydroxyapatite comprises hydroxyapatite, the first PMMA particle and the second PMMA particle, the mass ratio is 5:3.5:2.5, and the particle diameter of the first PMMA particle is 100 μ m, the second PMMA particle The particles have a particle size of 1000 μm; and

[0128] Porous hydroxyapatite is prepared by sintering, and the sintering process is shown in Table 2:

[0129] Table 2

[0130]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com