A gas-solid separation device and method

A gas-solid separation and gas-solid technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as unsatisfactory separation effect and cross-mixing, so as to improve utilization rate and overall reaction efficiency, and achieve good separation Effect, the effect of solving the problem of gas-solid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

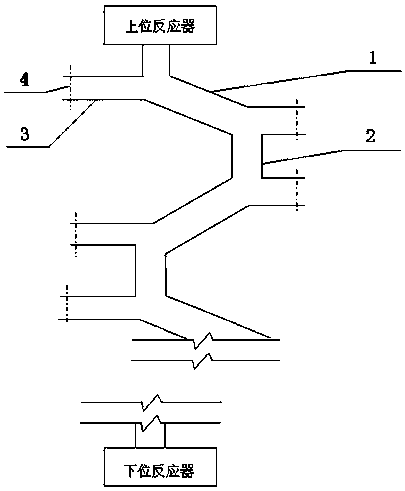

[0025] Gas-solid separation device, such as figure 1 As shown, the upper reactor and the lower reactor are sequentially connected to a repeated combination of three inclined planes 1 and vertical channels 2, the angle between the inclined plane and the horizontal plane is 40 degrees, and a gas channel 3 is connected to both ends of each inclined plane , screens 4 are provided at the openings of the gas passages 3 . The length of the slope 1 is 4m, and the length of the vertical channel 2 is 1m.

Embodiment 2

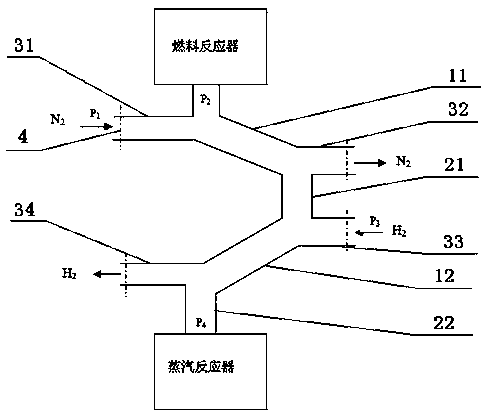

[0027] A gas-solid separation device used between a fuel reactor and a steam reactor, such as figure 2 As shown, between the fuel reactor and the steam reactor, the first inclined plane 11, the first vertical passage 21, the second inclined plane 12 and the second vertical passage 22 are connected in sequence, and the upper end of the first inclined plane 11 is connected with the second A gas channel 31, its lower end is connected with the second gas channel 32, the upper end of the second slope 12 is connected with the third gas channel 33, its lower end is connected with the fourth gas channel 34, each gas channel at the channel mouth A screen 4 is provided. The angle between the first inclined plane 11 and the second inclined plane 12 and the horizontal direction is 30 degrees, and their lengths are both 5 m; the lengths of the first vertical passage 21 and the second vertical passage 22 are both 2 m.

Embodiment 3

[0029] In the method of gas-solid separation using the gas-solid separation device of Example 2, after the reaction of the fuel in the fuel reactor and the oxygen carrier is completed, the oxygen carrier is reduced, and it enters the first slope 11 through the lower outlet of the reactor, where the mixed Part of the fuel gas and generated gas are fed into N from the first gas passage 31 2 , drawn from the second gas channel 32, N 2 The throughput is 0.1L / min. The pressure P at the lower outlet of the fuel reactor 2 is 0.1Mpa, so keep the pressure P at the inlet of the first gas channel 31 1 is 0.15Mpa; after the gas-solid separation of the first slope, the oxygen carrier enters the second slope 12 through the first vertical channel 21, and at the same time passes into H from the third gas channel 33 2 , drawn from the fourth gas channel 34, H 2 The amount of feed is 0.1L / min, and the pressure P4 at the inlet of the steam reactor is 0.18Mpa, so the pressure P at the inlet o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com