A reactor for inhibiting the floating of bacteria or sludge and its application

A reactor and antibacterial technology, applied in water/sludge/sewage treatment, water pollutants, chemical instruments and methods, etc., can solve the problems affecting the reaction efficiency of the reactor, activated sludge adhesion, etc., to improve the operation Flexibility, enhanced washout, enhanced effect of backmixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

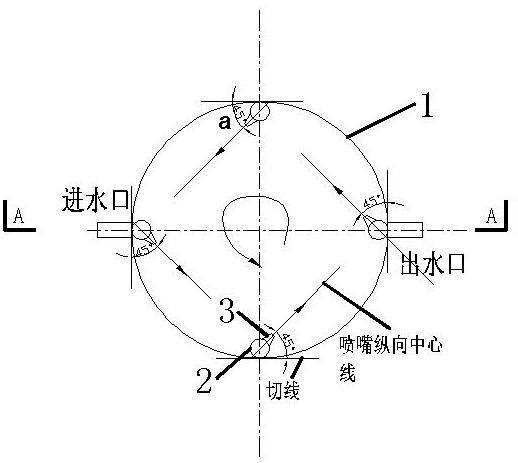

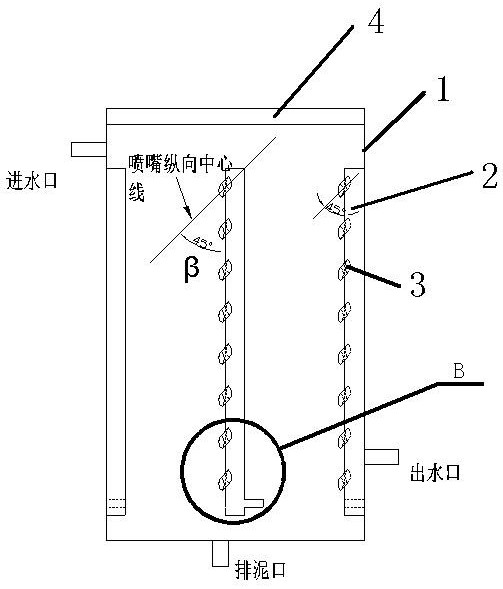

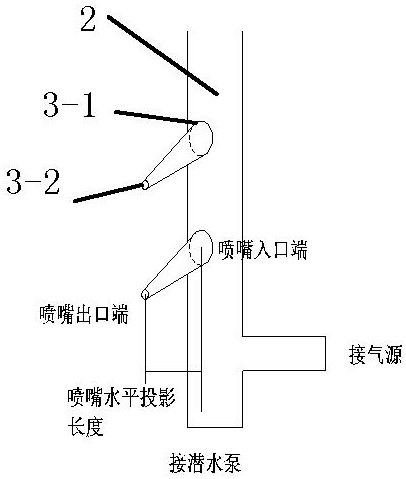

[0025] use figure 1 , 2 , The cylindrical reactor shown in 3, the cross-sectional diameter of the reactor is 50cm, and the height of the reactor is 100cm. The bottom of the channel is 10cm from the bottom of the reactor, and the top is 10cm higher than the highest liquid level. The cross-section diameter at the inlet end of the nozzle is 2 cm, the cross-sectional diameter at the exit end is 1 cm, the horizontal projection length is 2 cm, the vertical distance between each nozzle is 5 cm, α is 45°, and β is 45°. A submersible pump and an underwater aerator are connected to the bottom of the cylindrical channel.

[0026] Use the above-mentioned reactor to cultivate aerobic nitrifying bacteria, add the culture solution to the height of 30cm in the reactor, and then insert the nitrifying bacteria seed liquid at a volume fraction of 5%, so that the initial OD 600=0.05 (the absorbance value of the bacterial solution at a wavelength of 600nm). Then start the submersible pump and ...

Embodiment 2

[0028] use figure 1 , 2 , The cylindrical reactor shown in 3, the cross-sectional diameter of the reactor is 50cm, and the height of the reactor is 100cm. The bottom of the channel is 10cm from the bottom of the reactor, and the top is 10cm higher than the highest liquid level. The cross-sectional diameter of the inlet end of the nozzle is 1.5 cm, the cross-sectional diameter of the outlet end is 0.5 cm, the horizontal projection length is 2 cm, the vertical distance between each nozzle is 5 cm, and both α and β are 30°. A submersible pump and an underwater aerator are connected to the bottom of the cylindrical channel.

[0029] Use the above-mentioned reactor to cultivate aerobic nitrifying bacteria, add the culture solution to the height of 30cm in the reactor, and insert the nitrifying bacteria seed liquid at a volume fraction of 5%, so that the initial OD 600 =0.05. Then start the submersible pump and jet aerator, adjust the pressure of the pump to ensure that the wate...

Embodiment 3

[0031] The reactor described in Example 1 was used to carry out denitrification treatment of sewage, the concentration of nitrate nitrogen in the sewage was 100 mg / L, and the COD was 30 mg / L.

[0032] First, add sewage to be treated to a height of 50cm in the reactor, then add denitrification sludge to make the initial sludge concentration 500mg / L, add carbon source methanol according to C / N=3:1, and seal the reactor. Then start the submersible pump, adjust the pressure of the pump, ensure that the water body is ray ejected, the water body starts to rotate, and the back-mixing is very uniform. During the cultivation process, the pH is controlled at 7-8 and the temperature is 30-35°C. After 48 hours, the concentration of nitrate nitrogen in the reactor was 15 mg / L, and the COD was lower than 50 mg / L. At this time, the submersible pump was turned off, the bacteria were settled for 30 minutes, and then the sewage was discharged from the water outlet. During the cultivation proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com