Full oil base drilling fluid and preparation method thereof

A drilling fluid and all-oil-based technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of shortage, increased fluid loss, high oil solubility, etc., to improve the performance, simplify the production process, The effect of increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

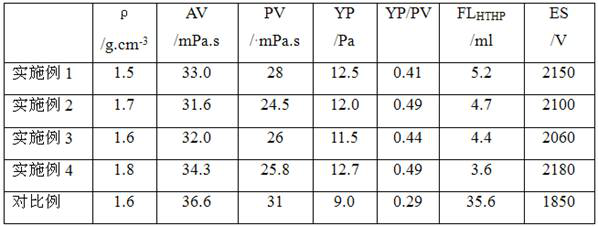

Examples

Embodiment 1

[0041] Put 120g of sulfur powder in a closed reaction kettle, heat it to 285°C, add 0.12g of 1-tetradecene after 40 minutes, and feed N at the same time 2 Keep the pressure at 1.0MPa. Heat 380g of asphalt with a softening point of 135.4°C in a closed raw material tank to a molten state, and pass N 2 Keep the pressure of the raw material tank at 0.8MPa, and react for 60 minutes. After the sulfur in the reactor melts and polymerizes, open the valves of the reactor and the asphalt raw material tank at the same time, spray the two liquids into the contact tower, and the molten sulfur enters from the upper part of the tower. , The molten bitumen enters from the lower part of the tower, so that the two are fully contacted in countercurrent and kept for 30 minutes. Open the discharge valve at the bottom of the contact tower, quickly spray the liquid into the quenching liquid containing 0.18g 6-chloro-1-hexanol for rapid cooling, and form uniform particles of asphalt and high-elastic...

Embodiment 2

[0044] Put 90g of sulfur powder in a closed reaction kettle, heat it to 295°C, add 0.18g of isoprene after 50 minutes, and feed N 2 Keep the pressure at 1.4MPa. Heat 410g of asphalt with a softening point of 147.6°C in a closed raw material tank to a molten state, and pass N 2 Keep the pressure of the raw material tank at 0.8MPa, and react for 55 minutes. After the sulfur in the reactor melts and polymerizes, open the valves of the reactor and the asphalt raw material tank at the same time, spray the two liquids into the contact tower, and the molten sulfur enters from the upper part of the tower. , The molten bitumen enters from the lower part of the tower, so that the two are fully contacted in countercurrent and kept for 40 minutes. Open the discharge valve at the bottom of the contact tower, quickly spray the liquid into the quenching liquid containing 0.16g of isopropanol for rapid cooling, and form uniform particles of asphalt and high elastic sulfur, which are suspende...

Embodiment 3

[0047] Put 160g of sulfur powder in a closed reaction kettle, heat it to 320°C, add 0.25g of 1-octadecene after 55 minutes, and feed N at the same time 2 Keep the pressure at 1.2MPa. Heat 340g of asphalt with a softening point of 158.4°C in a closed raw material tank to a molten state, and pass N 2 Keep the pressure of the raw material tank at 1.0MPa, and react for 90 minutes. After the sulfur in the reactor is melted and polymerized, open the valves of the reactor and the asphalt raw material tank at the same time, spray the two liquids into the contact tower, and the molten sulfur enters from the upper part of the tower. , The molten bitumen enters from the lower part of the tower, so that the two are fully contacted in countercurrent and kept for 50 minutes. Open the discharge valve at the bottom of the contact tower, quickly spray the liquid into the quenching liquid containing 0.20g of 4-chloro-1-butanol for rapid cooling, and form uniform particles of asphalt and high e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com