Preparation method of CBN (Cubic Boron Nitride) mixing type boron-doped diamond and Fe-based alloy catalyst

A kind of boron diamond, base alloy technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

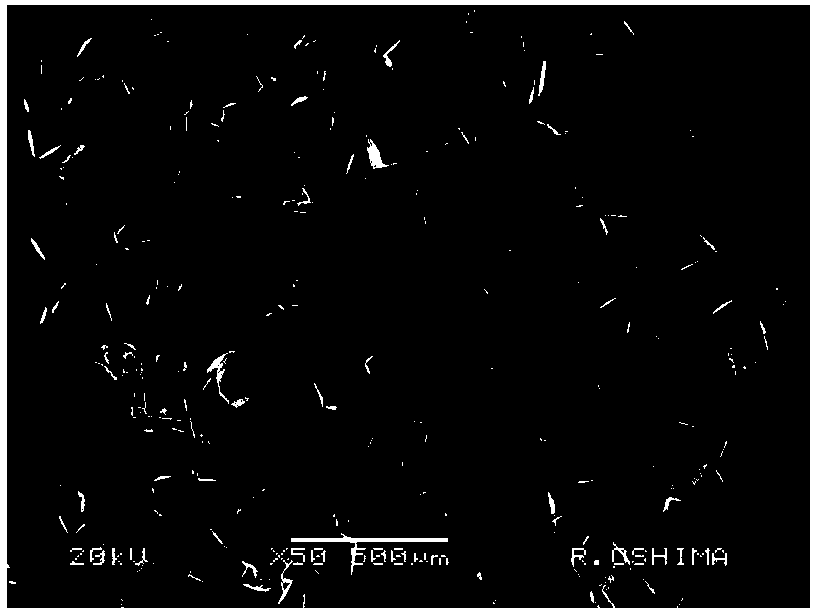

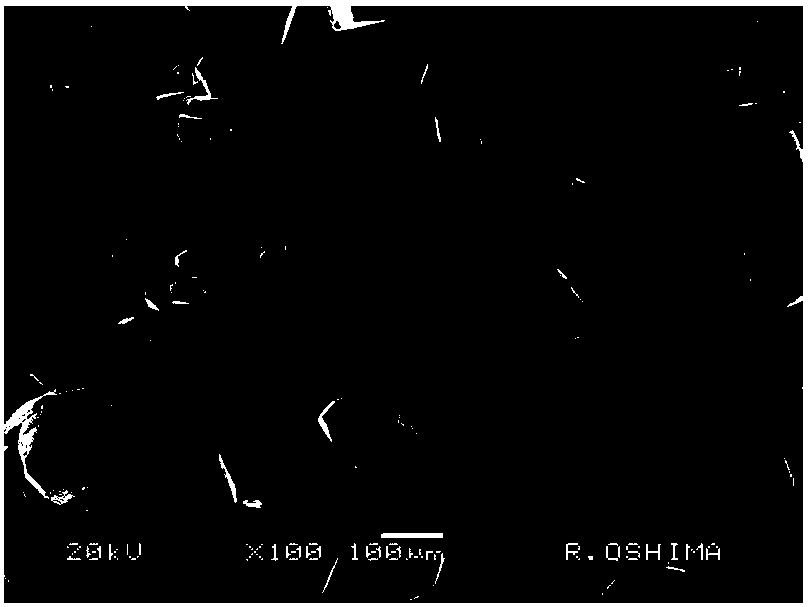

[0041] Compared with the traditional diamond synthesis process, CBN is added to the Fe-based alloy catalyst used in the preparation method of the present invention as the source of B element, compared to the current practice of directly adding boron or ordinary borides in the catalyst as the source of B element in the industry , using the B element in CBN to continuously dissolve and penetrate into graphite, and then transform into boron-containing diamond, the boron element in the obtained boron-containing diamond can be distributed more uniformly and the content is more stable, thereby further improving the heat resistance of boron-containing diamond resistance, oxidation resistance, chemical inertness and other properties. In addition, a certain amount of Mn element is added to the Fe-based alloy catalyst, which can effectively change the nucleation conditions of diamond and be more conducive to nucleation. In a preferred embodiment, the Fe-based alloy catalyst includes: 28...

Embodiment

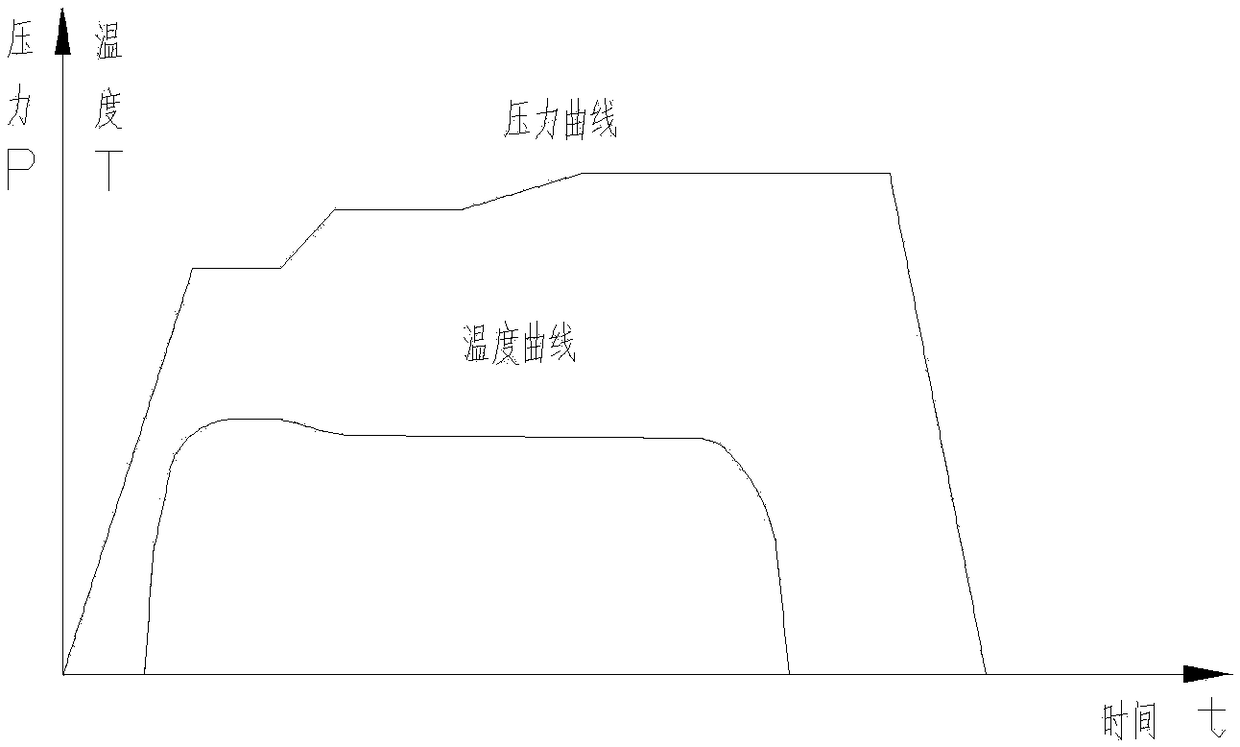

[0055] The synthesis steps are:

[0056] (1) Get fine graphite powder and Fe-based alloy catalyst powder with 400 meshes, mix by weight ratio 11:9, the composition and content of described Fe-based alloy catalyst powder are recorded as: Ni: 28%, CBN: 3%, Co: 5%, Mn: 3%, the balance is Fe;

[0057] (2) Put the raw material obtained in step (1) into a three-dimensional mixer and mix for 6 hours, and after isostatic pressing at 280Mpa, break it into particles smaller than 100 meshes to obtain the mixed material;

[0058] (3) Put the mixed material obtained in step (2) into the mold, and then press it into a columnar stem on a four-column press. The stem size: Φ55mm×43mm, and the stem density: 3.5g / cm 3 , put the formed core column into a vacuum furnace, vacuum treatment at 1100 ° C, fully remove oxygen and other volatile impurities, and naturally cool down to room temperature;

[0059] (4) Put the core column into the diamond synthesis block, and then put the diamond synthesis ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com