Manufacturing method of ceramic material

A manufacturing method and technology of ceramic materials, which are applied in the fields of instruments, electrical digital data processing, digital data processing components, etc., can solve the problems of excessive heat flux and poor high temperature resistance, and achieve good high temperature resistance and economical efficiency. Duration, the effect of increasing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

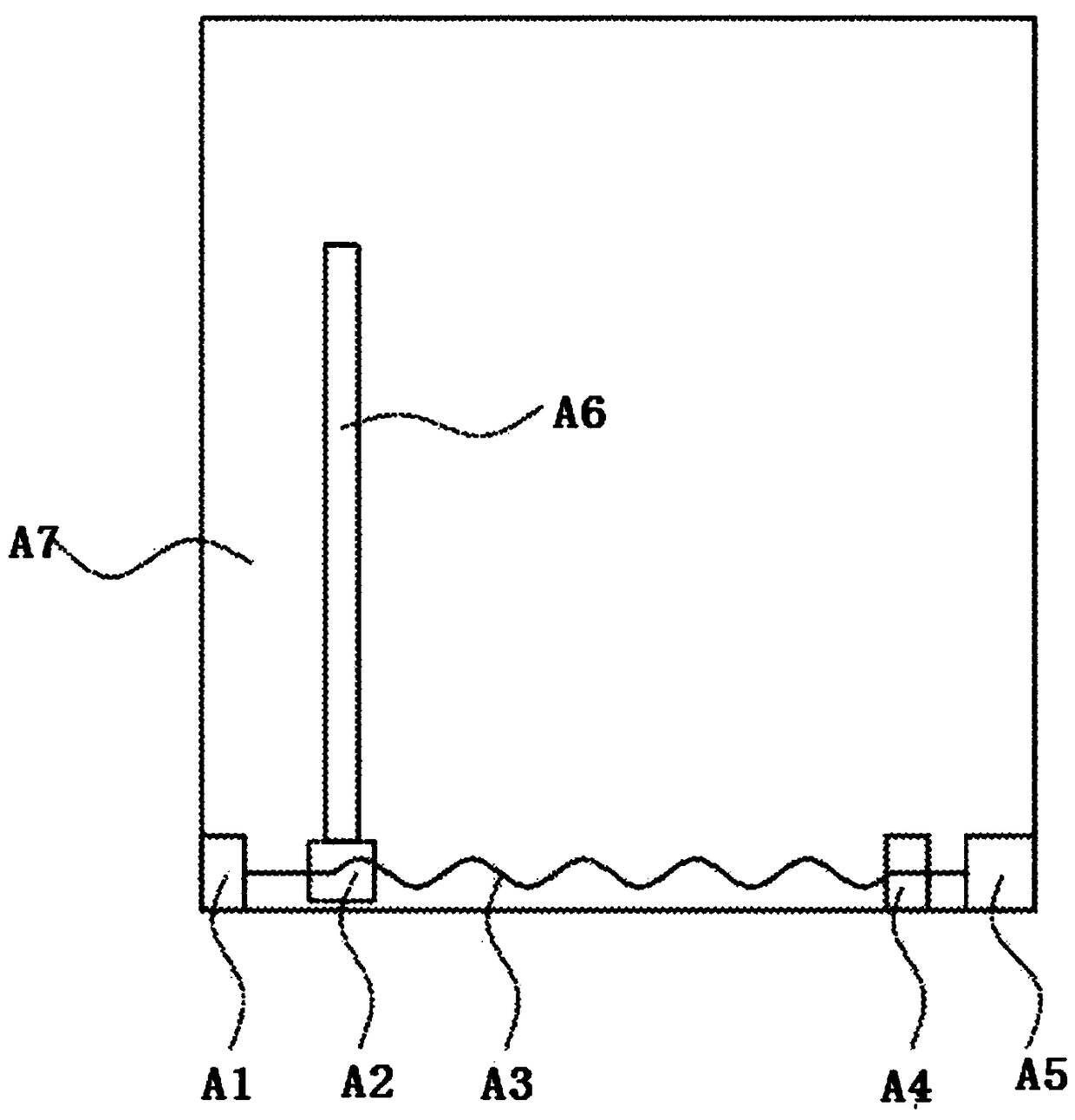

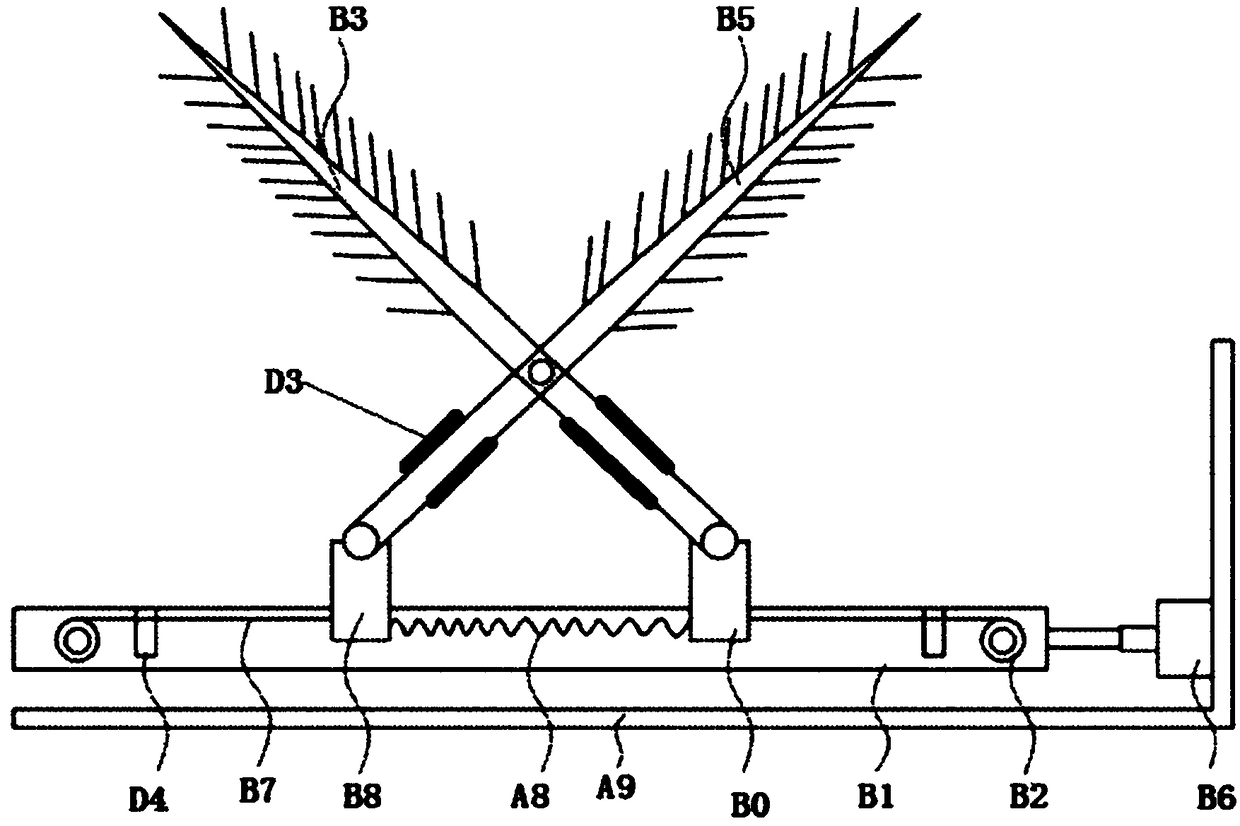

[0036] like figure 1 and figure 2 Shown, the manufacture method of ceramic material, the steps are as follows:

[0037]Step 1: Construct silica fume. The silica fume is constructed by ferroalloy when ferrosilicon and industrial silicon are smelted. A large amount of highly volatile SiO2 and Si gases are produced in the submerged electric furnace. After the gas is discharged, it oxidizes, condenses and precipitates with air rapidly. The obtained silica fume is ground with a grinder, and then passed through a filter screen with a filter hole diameter of 0.106mm and a filter screen with a filter hole diameter of 0.0750mm;

[0038] Put the filter screen silica fume with a filter hole diameter of 0.106mm and the filter screen with a filter hole diameter of 0.0750mm and mix them together according to the weight ratio of 2:1;

[0039] Step 2: Weighing the first ingredient, said weighing the first ingredient is to weigh 18 parts by weight of silica fume, 18 parts by weight of white...

Embodiment 2

[0066] The manufacture method of ceramic material, the steps are as follows:

[0067] Step 1: Construct silica fume. The silica fume is constructed by ferroalloy when ferrosilicon and industrial silicon are smelted. A large amount of highly volatile SiO2 and Si gases are produced in the submerged electric furnace. After the gas is discharged, it oxidizes, condenses and precipitates with air rapidly. The obtained silica fume is ground with a grinder, and then passed through a filter screen with a filter hole diameter of 0.106mm and a filter screen with a filter hole diameter of 0.0750mm;

[0068] Put the filter screen silica fume with a filter hole diameter of 0.106mm and the filter screen with a filter hole diameter of 0.0750mm and mix them together according to the weight ratio of 2:1;

[0069] Step 2: Weighing the first ingredient, said weighing the first ingredient is to weigh 25 parts by weight of silica fume, 21 parts by weight of white carbon black, and 7 parts by weight...

Embodiment 3

[0096] The manufacture method of ceramic material, the steps are as follows:

[0097] Step 1: Construct silica fume. The silica fume is constructed by ferroalloy when ferrosilicon and industrial silicon are smelted. A large amount of highly volatile SiO2 and Si gases are produced in the submerged electric furnace. After the gas is discharged, it oxidizes, condenses and precipitates with air rapidly. The obtained silica fume is ground with a grinder, and then passed through a filter screen with a filter hole diameter of 0.106mm and a filter screen with a filter hole diameter of 0.0750mm;

[0098] Put the filter screen silica fume with a filter hole diameter of 0.106mm and the filter screen with a filter hole diameter of 0.0750mm and mix them together according to the weight ratio of 2:1;

[0099] Step 2: Weighing the first ingredient, said weighing the first ingredient is to weigh 32 parts by weight of silica fume, 24 parts by weight of white carbon black, and 10 parts by weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com