Epoxy resin curing agent and preparation method

An epoxy resin curing and curing agent technology, which is applied in the preparation of imino compounds, organic chemistry, etc., can solve the problems that epoxy resin is difficult to process and recycle, so as to alleviate environmental pollution and waste of resources, meet the needs of use, Effect of good solvent resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

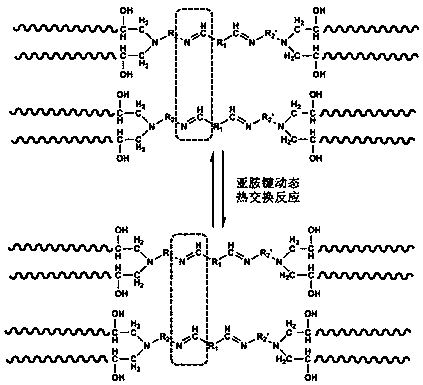

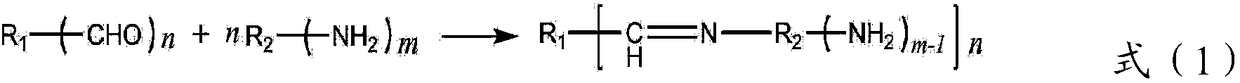

Method used

Image

Examples

Embodiment 1

[0028] Step 1: Weigh 15.0g of ethylenediamine and dissolve it in 30ml of methanol, stir at room temperature for 10min to obtain a clear solution 1; weigh 16.5g of terephthalaldehyde and dissolve it in 15ml of methanol, and ultrasonically treat it for 5min at room temperature to obtain a clear solution 2. Heat solution 1 to 40°C, and slowly add solution 2 drop by drop to rapidly stirred solution 1 with a constant pressure dropping funnel, and after fully reacting for 12 hours, vacuum-dry to obtain an epoxy curing agent containing an imine bond structure, The structural formula is as follows:

[0029]

[0030] Step 2: Mix 100g of bisphenol A epoxy resin solution E51 and 28g of the above-mentioned curing agent evenly, put it in a vacuum oven for 30-50 minutes to vacuumize and defoam, and pour the defoamed solution into a preheated stainless steel mold The epoxy resin was obtained after curing at 60°C for 4 hours, at 80°C for 4 hours, and after cooling and demoulding.

[0031...

Embodiment 2

[0033] Step 1: Weigh 50g of diaminodiphenylmethane (DDM) and dissolve it in 60ml of methanol, stir at room temperature for 10min to obtain a clear solution 1; weigh 16.7g of terephthalaldehyde and dissolve it in 15ml of methanol, and sonicate at room temperature for 5min , a clear solution 2 was obtained. Heat solution 1 to 40°C, and slowly add solution 2 drop by drop to rapidly stirred solution 1 with a constant pressure dropping funnel, and after fully reacting for 12 hours, vacuum-dry to obtain an epoxy curing agent containing an imine bond structure, The structural formula is as follows:

[0034]

[0035] Step 2: Mix 100g of bisphenol A epoxy resin solution E51 and 60g of the above-mentioned curing agent evenly, put it in a vacuum oven for 30-50 minutes to vacuumize and defoam, and pour the defoamed solution into a preheated stainless steel mold In the middle, cure at 60°C for 4 hours, and then cure at 100°C for 4 hours, and then obtain the epoxy resin after cooling an...

Embodiment 3

[0038] Step 1: Weigh 20g of ethylenediamine and dissolve it in 30ml of ethanol / dichloromethane solvent (volume ratio 8:2), stir at room temperature for 10min to obtain a clear solution 1; weigh 18g of trimesaldehyde and dissolve it in 15ml of ethanol / In dichloromethane solvent, sonication at room temperature for 5 min, a clear solution 2 was obtained. Heat solution 1 to 40°C, and slowly add solution 2 drop by drop to rapidly stirred solution 1 with a constant pressure dropping funnel, and after fully reacting for 12 hours, vacuum-dry to obtain an epoxy curing agent containing an imine bond structure, The structural formula is as follows:

[0039]

[0040] Step 2: Mix 100g of bisphenol A epoxy resin solution E51 and 25g of the above-mentioned curing agent evenly, put it in a vacuum oven for 30-50 minutes to vacuumize and defoam, and pour the defoamed solution into a preheated stainless steel mold The epoxy resin was obtained after curing at 60°C for 4 hours, at 90°C for 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com