Reparation method of gradient porous metal organic framework ZIF (Zeolitic Imidazolate Framework)-8

A metal-organic framework, ZIF-8 technology, applied in the field of preparation of gradient porous metal-organic framework ZIF-8, can solve the problems of difficult ligand synthesis, interpenetration of material structure, unstable properties, etc., and achieves convenient industrial operation, Stable performance and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

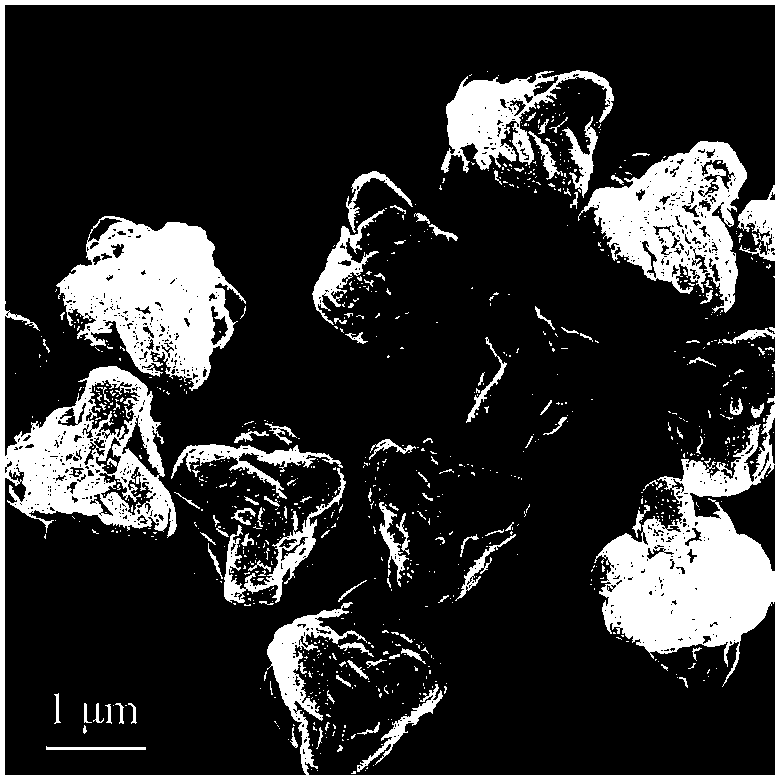

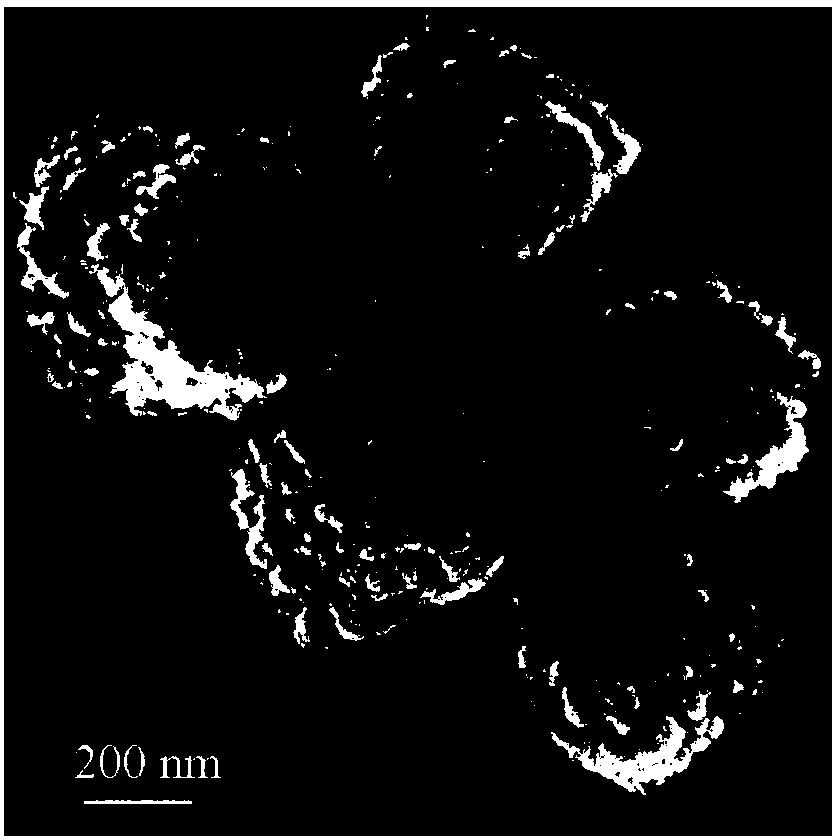

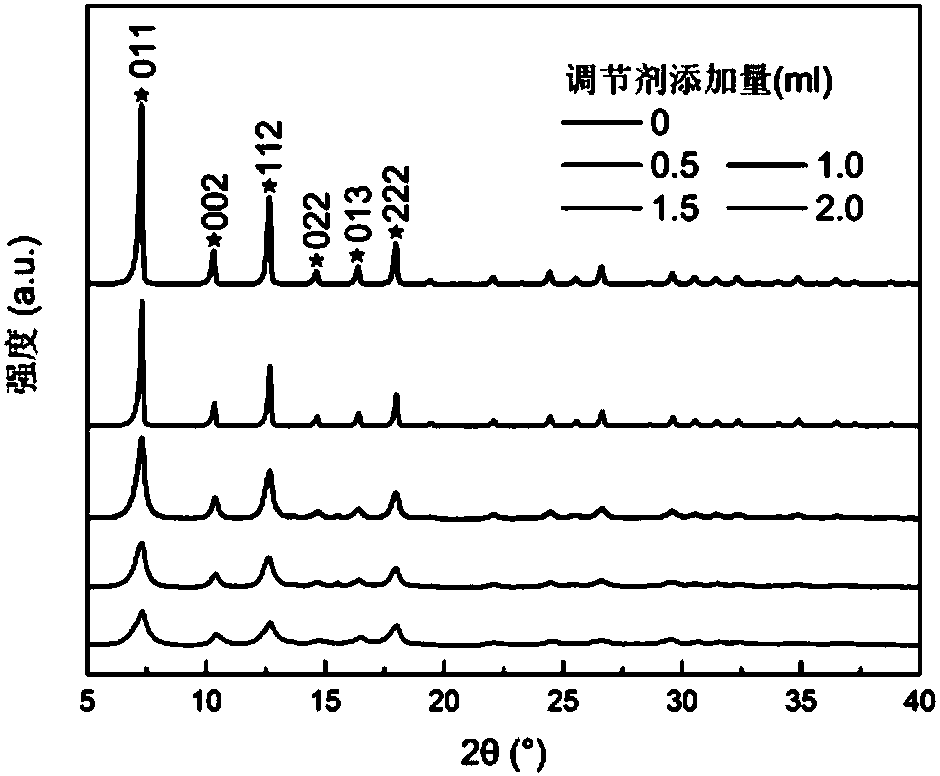

Embodiment 1

[0027] Weigh 4.10g of 2-methylimidazole into a 250mL beaker, then add 50mL of deionized water, dissolve thoroughly under magnetic stirring, and measure 0.5ml of polydiallyldimethylammonium chloride solution with a pipette (20wt.%) was added in the above-mentioned beaker, stirred and mixed evenly; Weighed 2.20g zinc acetate dihydrate and joined in the 100ml beaker, then added 30ml deionized water to dissolve the divalent zinc salt; Divalent zinc salt solution was mixed with 2-methylimidazole solution, and stirred and reacted for 1.0 h under normal temperature and pressure conditions to obtain a milky white suspension; the white solid product was obtained by filtration or centrifugation, and the product was washed in deionized water Multiple times to remove unreacted monomers or regulators, and the obtained product is dried in a vacuum oven to obtain a gradient porous metal-organic framework ZIF-8.

Embodiment 2

[0029] Weigh 4.10g of 2-methylimidazole into a 250mL beaker, then add 50mL of deionized water, dissolve thoroughly under magnetic stirring, and measure 1.5ml of polydiallyldimethylammonium chloride solution with a pipette (20wt.%) was added in the above-mentioned beaker, stirred and mixed evenly; Weighed 2.20g zinc acetate dihydrate and joined in the 100ml beaker, then added 30ml deionized water to dissolve the divalent zinc salt; Divalent zinc salt solution was mixed with 2-methylimidazole solution, and stirred and reacted at normal temperature and pressure for 1.5 hours to obtain a milky white suspension; the white solid product was obtained by filtration or centrifugation, and the product was washed in deionized water Multiple times to remove unreacted monomers or regulators, and the obtained product is dried in a vacuum oven to obtain a gradient porous metal-organic framework ZIF-8.

Embodiment 3

[0031] Weigh 6.15g of 2-methylimidazole into a 250mL beaker, then add 50mL of deionized water, dissolve thoroughly under magnetic stirring, and measure 0.5ml of polydiallyldimethylammonium chloride solution with a pipette (20wt.%) was added in the above-mentioned beaker, stirred and mixed evenly; Weighed 2.20g zinc acetate dihydrate and joined in the 100ml beaker, then added 30ml deionized water to dissolve the divalent zinc salt; Divalent zinc salt solution and 2-methylimidazole solution were mixed, and stirred and reacted at normal temperature and pressure for 2.0 hours to obtain a milky white suspension; the white solid product was obtained by filtration or centrifugation, and the product was washed in deionized water Multiple times to remove unreacted monomers or regulators, and the obtained product is dried in a vacuum oven to obtain a gradient porous metal-organic framework ZIF-8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com