Cellar type biomass charcoal combination kiln

A technology of biomass charcoal and cellars, which is applied in the direction of biofuel, special dry distillation, and petroleum industry. Production cycle, the effect of eliminating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

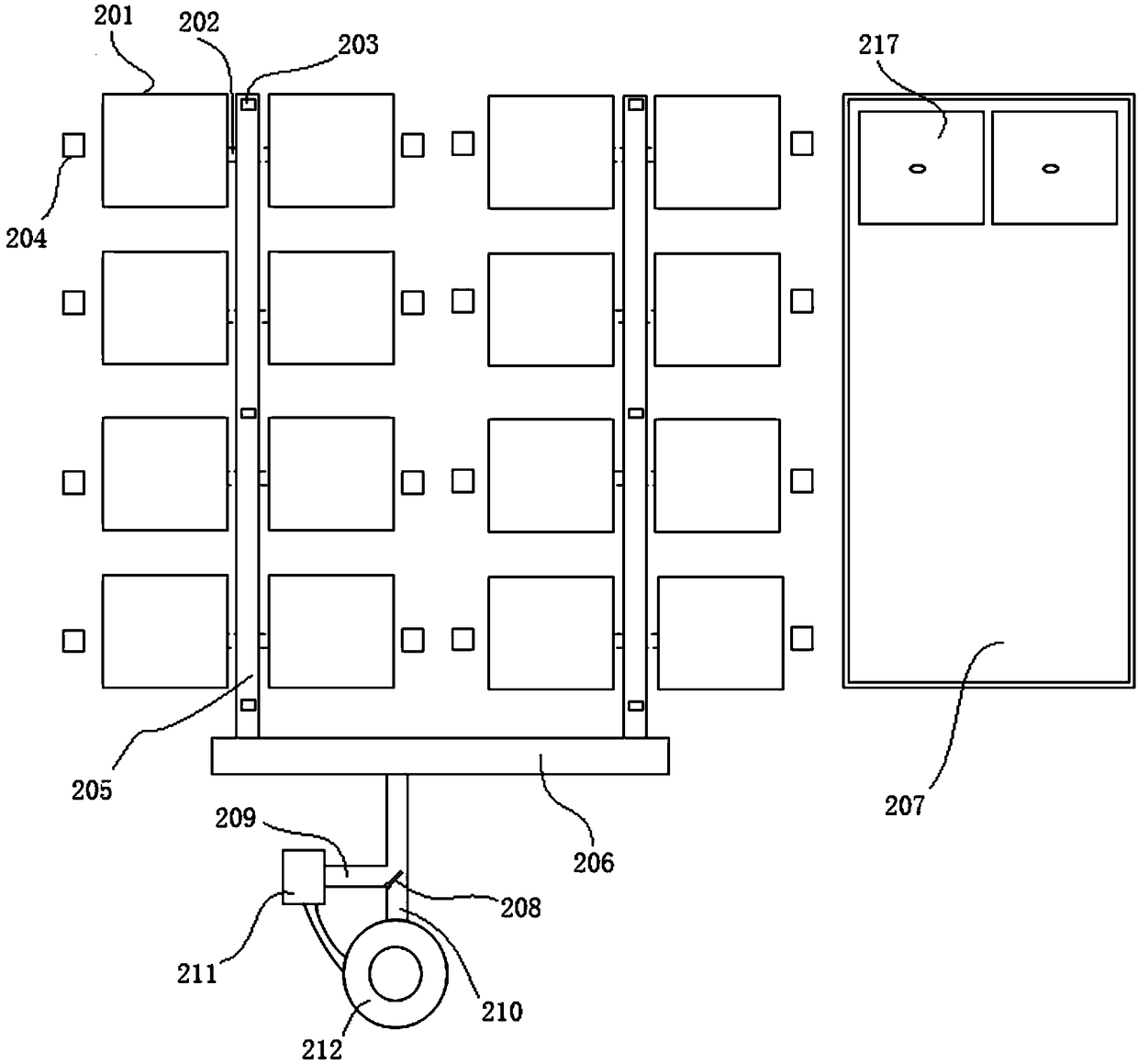

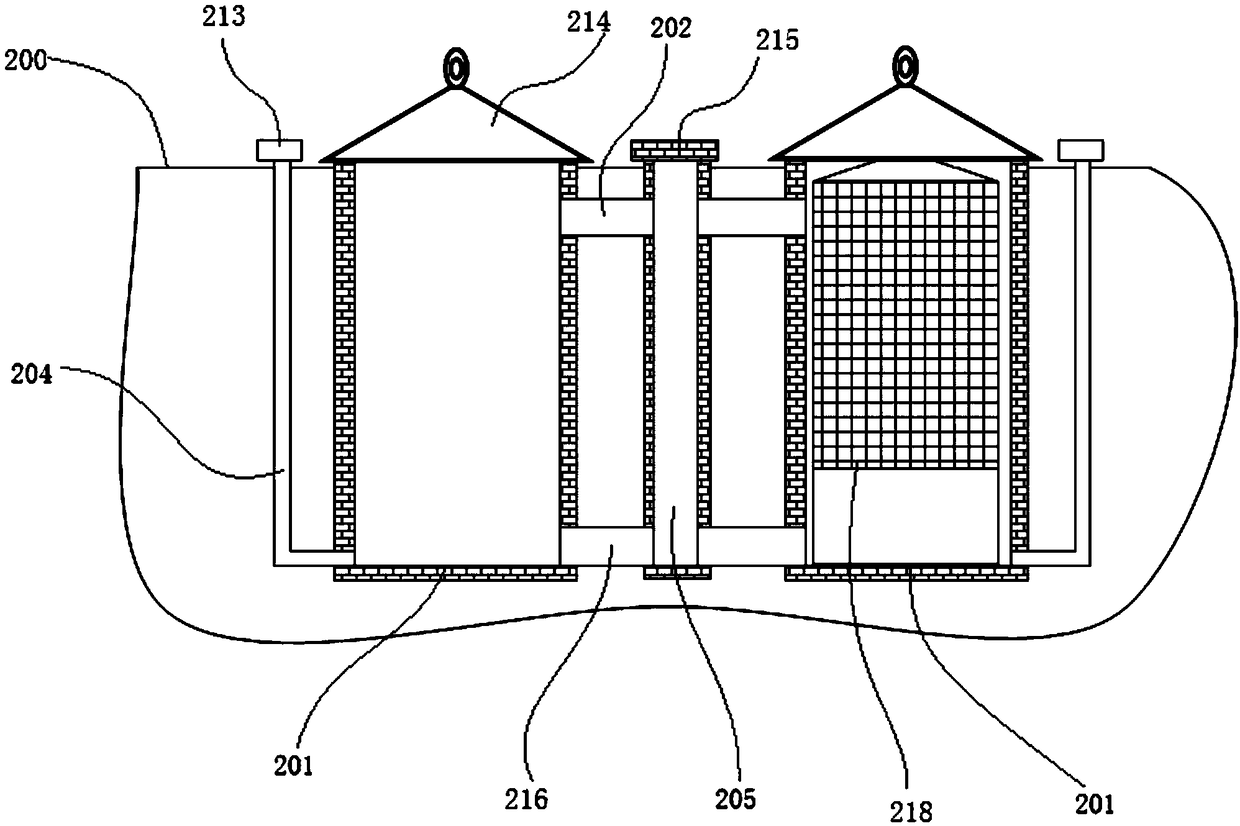

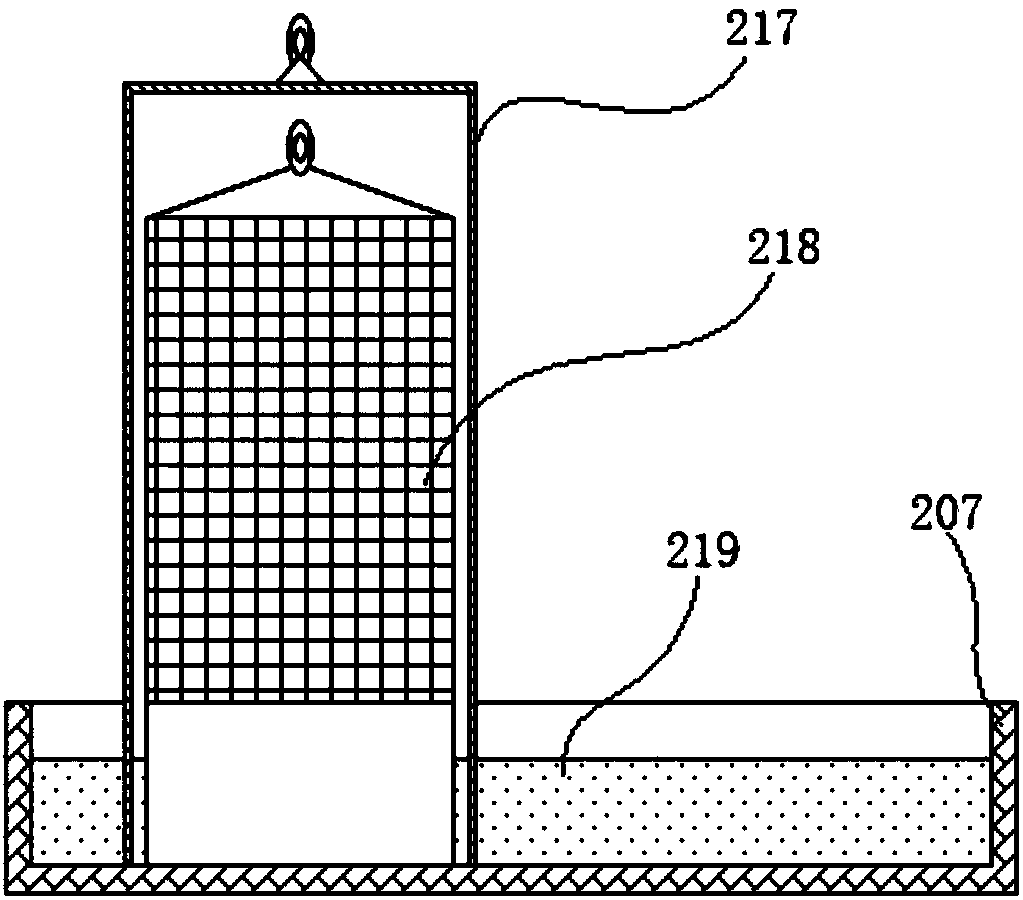

[0018] Referring to the accompanying drawings, which reflect a specific structure of the present invention, the cellar-type biomass charcoal combined kiln includes sixteen kiln bodies 201 distributed in a matrix of 4 rows×4 columns, and the kiln bodies 201 are set under the ground 200 cellar structure. The distance between each kiln body is 40-50 cm. A pre-combustion heat conduction tunnel 205 is set between the two rows of kiln bodies 201. One end of the two pre-combustion heat conduction tunnels 205 is connected to the total heat conduction tunnel 206, and the total heat conduction tunnel 206 is connected to the first heat supply pipeline 210 and the second heat supply pipeline through the diverter door 208. Two heat supply pipelines 209 , the first heat supply pipe 210 communicates with the furnace of the gas boiler 212 , and the second heat supply pipe 209 communicates with the heater of the preheating water tank 211 of the gas boiler 212 . The combustible gas in the carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com