Damping load reducing sound barrier

A sound barrier and damping technology, which is applied in construction, noise absorption devices, etc., can solve the problems of ethylene-propylene rubber flame retardancy, poor oil resistance and air tightness, poor self-adhesiveness and mutual adhesion of ethylene-propylene rubber, and increased installation time. , to achieve long service life, reduce workload and reduce maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

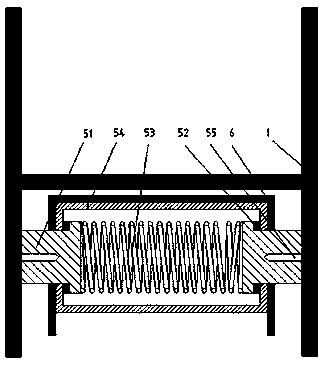

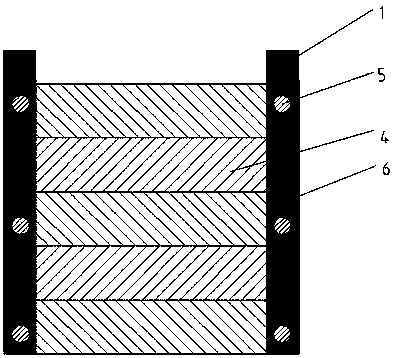

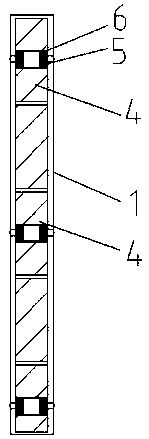

[0030] Figures 1-4 show the second embodiment of the present invention: a damping load reduction sound barrier, comprising a sound barrier body 4 and an H-shaped steel sound barrier column 1, on both sides of the sound barrier body 4 A damping structure is provided between the H-shaped steel sound barrier column 1. The damping structure is arranged between the two sides of the sound barrier body 4 and the H-shaped steel sound barrier column 1, so that the force is uniform under the condition of bearing the pulsating load, and the entire sound barrier body 4 and the H-shaped steel sound barrier column 1 serve as A whole to bear the pulsating load, each part is evenly stressed, no local damage will occur, and the maintenance cost is reduced. The damping structure is arranged symmetrically on both sides of the sound barrier body 4, which is convenient for installation and mass production Manufacturing, and save installation time, improve work efficiency and reduce costs.

[0031...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com