A method of making high precision mems inertial sensor using soi sheet

An inertial sensor, high-precision technology, applied in directions such as navigation through speed/acceleration measurement, can solve the problems of low precision of inertial sensors, low cross-axis sensitivity, etc., achieve low cross-sensitivity, low mechanical and thermal noise, and simplify the production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

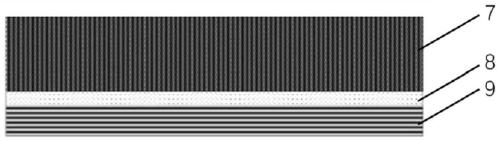

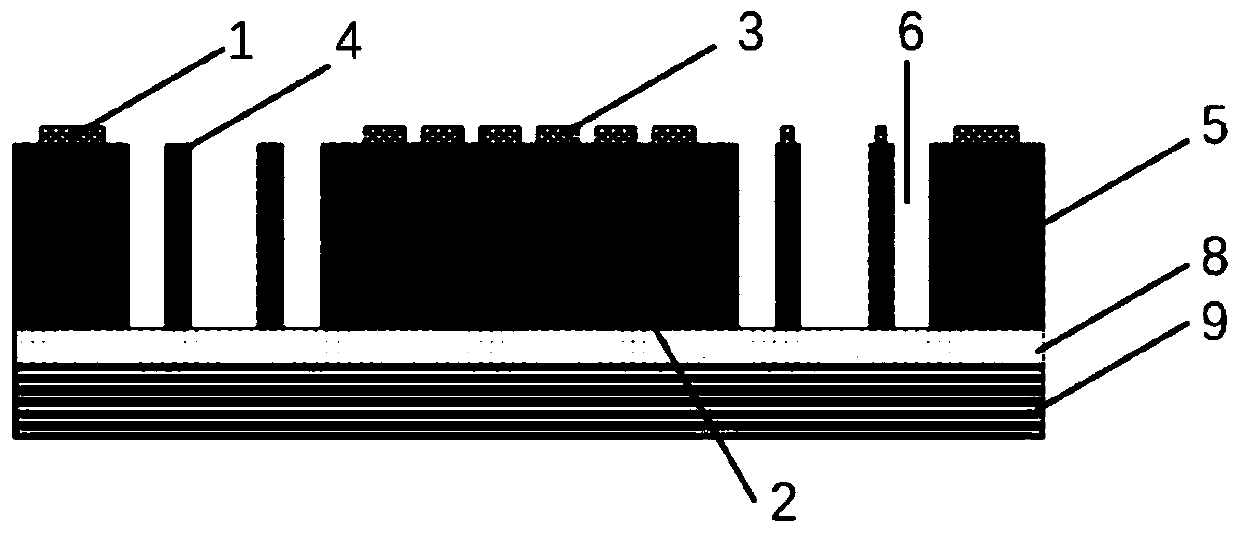

[0045] The material used is an SOI wafer, the thickness of the device layer 7 is 500 μm, the thickness of the sacrificial layer 8 is 1 μm, and the thickness of the supporting layer 9 is 100 μm. The device layer 7 can be a silicon layer, and the sacrificial layer 8 can be SiO 2 layer, the supporting layer 9 may be a silicon layer.

[0046] The realization technique of a kind of high-precision MEMS inertial sensor provided by the present invention comprises the following steps:

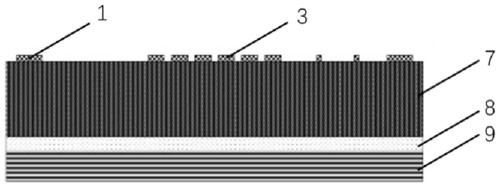

[0047] (1) complete the making of metal capacitor pole plate 3 and package contact point 1 on SOI silicon chip device layer 7, as Figure 2a shown. Further include the following steps:

[0048] (1-1) Carry out organic cleaning and oxygen plasma cleaning to the silicon wafer;

[0049] (1-2) Electron beam evaporation is used to plate titanium 40nm and gold 200nm on the surface of the silicon wafer (both refer to the thickness);

[0050] (1-3) performing photolithography on the surface of the metal la...

Embodiment 2

[0075] The material used is an SOI wafer, the thickness of the device layer 7 is 400 μm, the thickness of the sacrificial layer 8 is 2 μm, and the thickness of the supporting layer 9 is 50 μm.

[0076] The realization technique of a kind of high-precision MEMS inertial sensor provided by the present invention comprises the following steps:

[0077] (1) On the device layer 7 of the SOI silicon wafer, the fabrication of the metal capacitor plate 3 and the packaging contact point 1 is completed. Further include the following steps:

[0078] (1-1) Carry out organic cleaning and oxygen plasma cleaning to the silicon wafer;

[0079] (1-2) Evenly apply double-layer glue on the surface of the silicon wafer, after exposure and development, rinse with flowing deionized water for 5 minutes;

[0080] (1-3) Surface treatment of the sample, such as oxygen plasma cleaning, to ensure the cleanliness of the sample surface;

[0081] (1-4) Electron beam evaporation is used to plate titanium 40n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com