Elastic current collector, preparation method of elastic current collector, battery electrode plate, and flexible lithium ion battery

A technology for lithium-ion batteries and battery electrodes, applied in battery electrodes, electrode carriers/current collectors, secondary batteries, etc., can solve the problem of shedding of the active material film layer, the high flexibility of the current collector cannot be achieved, and the active material film layer cannot be guaranteed Combination with metal current collectors and other issues to achieve the effect of increasing the interface contact area, improving cycle stability, and good tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

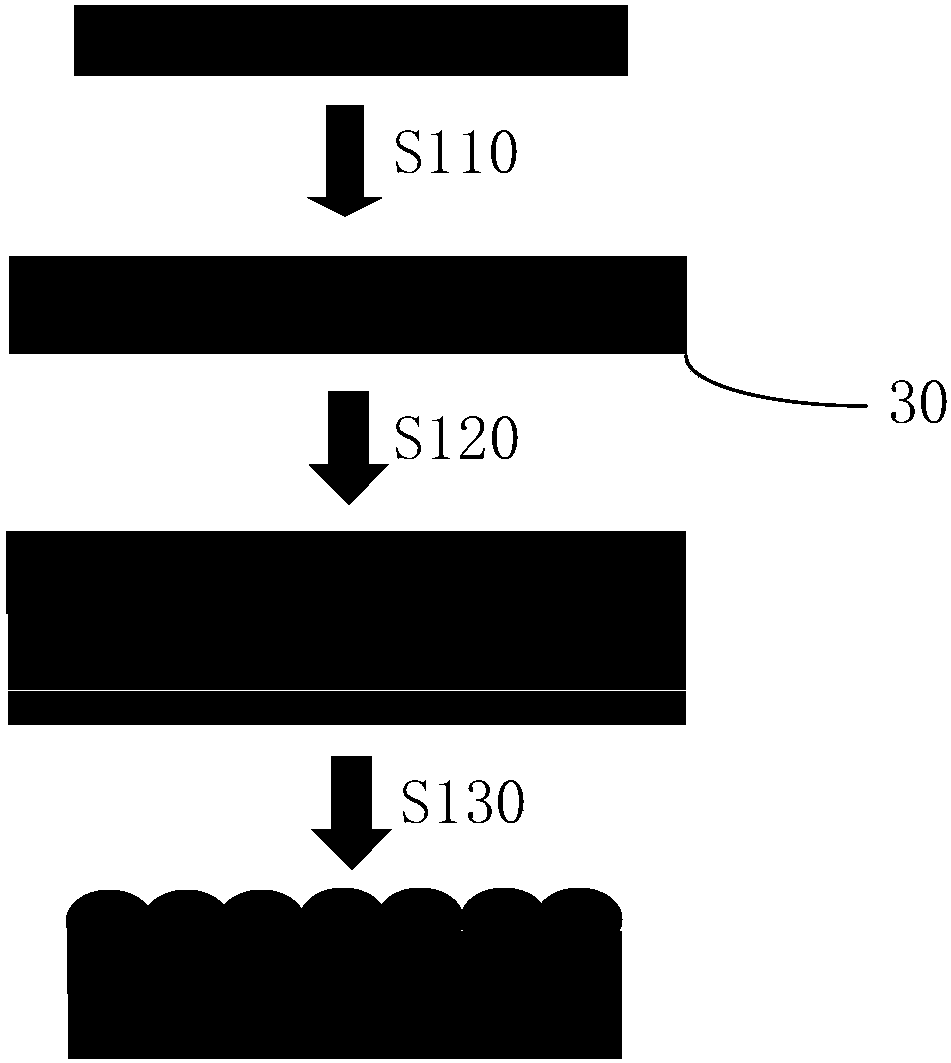

[0050] Correspondingly, an embodiment of the present invention provides a method for preparing an elastic current collector, including the following steps:

[0051] S10, stretch the elastic polymer substrate from the transverse direction and the longitudinal direction and fix it on the rigid base;

[0052] S20, depositing and preparing a conductive layer on the surface of the stretched elastic polymer substrate, the material of the conductive layer includes metal and / or carbon material;

[0053] S30. Peel the elastic polymer substrate deposited with the conductive layer from the rigid base, release the tensile force to return to the original size of the elastic polymer substrate, and the conductive layer is formed on the elastic polymer substrate A corrugated structure is an elastic current collector. The elastic current collector includes an elastic polymer substrate and a conductive layer disposed on the elastic polymer substrate. The conductive layer has a corrugated structure, an...

Embodiment 1

[0069] A method for preparing an elastic current collector includes the following steps:

[0070] S110: The purified polyimide film substrate is stretched in the transverse direction and the longitudinal direction at an elongation of 30% and then fixed on the rigid base;

[0071] S120: Place the rigid substrate fixed with the polyimide film on the substrate holder of the vacuum chamber, and extract the gas in the vacuum chamber. When the vacuum degree in the vacuum chamber reaches -7 Evaporation starts at Torr, and the metal copper is sputtered with an electron beam with a power of 600W, and the metal copper starts to evaporate when heated; the sputtering rate is measured with the crystal oscillator of the film thickness meter, when the rate can reach stably When, open the baffle of the vacuum chamber, rotate the substrate holder at a speed of 20 revolutions per minute, evaporate for 30 minutes, and then cool down to form a continuous and bright metal copper conductive layer on the ...

Embodiment 2

[0082] A method for preparing an elastic current collector includes the following steps:

[0083] S210: The purified polydimethylsiloxane (PDMS) substrate is stretched in the transverse and longitudinal directions at an elongation of 200% and then fixed on the rigid substrate;

[0084] S220: Then the PDMS substrate fixed on the rigid substrate is subjected to copper immersion treatment for 15 minutes, the pH of the copper immersion solution is 11-13, and the temperature is 25°C-45°C; after washing with water, the nickel immersion treatment is performed for 3.5 minutes, and the pH of the nickel precipitation solution is It is 4.5-6.3, the temperature is 65℃-78℃; after washing, electroplating nickel is carried out for 11 minutes. The treatment conditions are: stainless steel as anode, elastic polymer as cathode, direct current or pulsed electricity, metal nickel plating solution pH It is 3.3-5.1, and the temperature is 35℃-52℃, forming a metal nickel copper conductive layer;

[0085] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Amine equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com