Plum flower shaped jujube crisps and processing technology thereof

A processing technology, jujube flower technology, applied in baking, dough processing, baked food, etc., can solve the problems of reducing the nutritional value of jujube flower crisps, threatening consumers' health, affecting consumer health, etc., and improving antioxidant performance , rich taste and extended shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

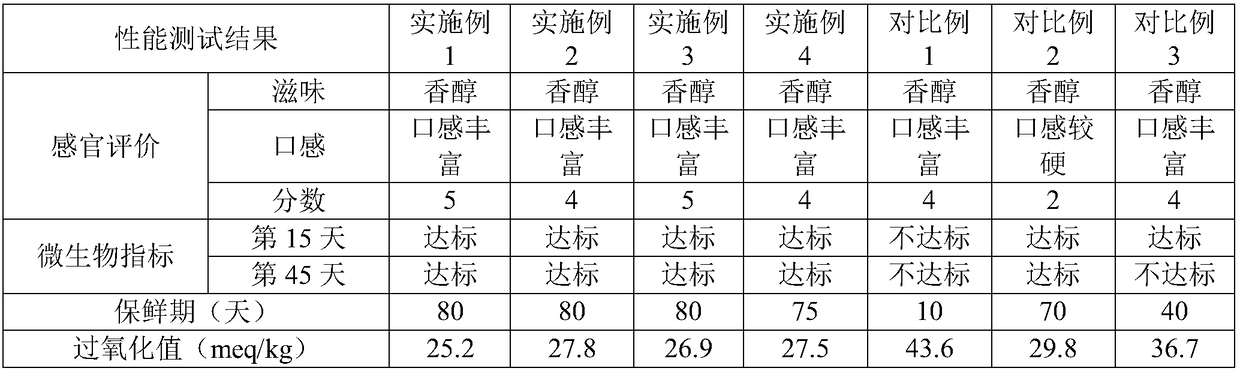

Examples

Embodiment 1

[0039] Pretreatment of rich and strong powder: pass the rich and strong powder through a 70-mesh sieve;

[0040] Extraction of active substances from jujube peels: Take fresh jujubes of uniform size and clean them, separate the jujube peels of the fresh jujubes, and smash the jujube peels for later use; take 12 g of jujube peels and put them in 110 g of a mixed solution of ethanol and ethyl acetate , wherein the volume fraction of the mixed solution of ethanol and ethyl acetate is 95%, and the mass ratio of ethanol to ethyl acetate is 1:2; after 2250W ultrasonic extraction for 22min, centrifugation for 12min at a speed of 5250r / min, take The supernatant was obtained to obtain a mixed solution containing the active substance of jujube peel; then ethanol and ethyl acetate were rotary evaporated under the condition of 37 ° C, and deionized water was added to 55 mL to obtain the active extract of jujube peel;

[0041] Hepi noodles: take 3kg of jujube peel active extract, 12.5kg of...

Embodiment 2

[0049] Pretreatment of rich and strong powder: pass the rich and strong powder through a 60 mesh sieve;

[0050]Extraction of active substances from jujube peels: Take fresh jujubes of uniform size and clean them, separate the jujube peels of the fresh jujubes, and smash the jujube peels for later use; take 14g of jujube peels and put them in 100g of a mixed solution of ethanol and ethyl acetate , wherein the volume fraction of the mixed solution of ethanol and ethyl acetate is 95%, and the mass ratio of ethanol to ethyl acetate is 1:2; after 24min of ultrasonic extraction at 2500W, centrifugation at a rate of 5000r / min for 12min, take The supernatant was obtained to obtain a mixed solution containing the active substance of jujube peel; then ethanol and ethyl acetate were rotary evaporated at 35°C, and deionized water was added to 50 mL to obtain the active extract of jujube peel;

[0051] Hepi noodles: take 2kg of jujube peel active extract, 10kg of lard, and 18kg of water, ...

Embodiment 3

[0058] Pretreatment of rich and strong powder: pass the rich and strong powder through an 80-mesh sieve;

[0059] Extraction of active substances from jujube peels: Clean fresh jujubes of uniform size, separate the jujube peels of the fresh jujubes, smash the jujube peels for later use; take 10 g of jujube peels and put them in 100 g of a mixed solution of ethanol and ethyl acetate , wherein the volume fraction of the mixed solution of ethanol and ethyl acetate is 95%, and the mass ratio of ethanol to ethyl acetate is 1:2; after 20min of ultrasonic extraction at 2500W, centrifugation at a rate of 5500r / min for 14min, take The supernatant is obtained to obtain a mixed solution containing the active substance of jujube peel; then ethanol and ethyl acetate are rotary evaporated under the condition of 39 ° C, and deionized water is added to 50 mL to obtain the active extract of jujube peel;

[0060] Hepi noodles: take 4kg of active extract of jujube peel, 10kg of lard, and 18kg of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com