Method for preparing dried apples through combination of ultrasonic osmotic dehydration and microwave drying

A technology of microwave drying and osmotic dehydration, which is applied in the directions of food ultrasonic treatment, food drying, and the function of food ingredients, can solve problems such as unfavorable human health and health preservation needs, and achieve the advantages of short interval time, high moisture content and food safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

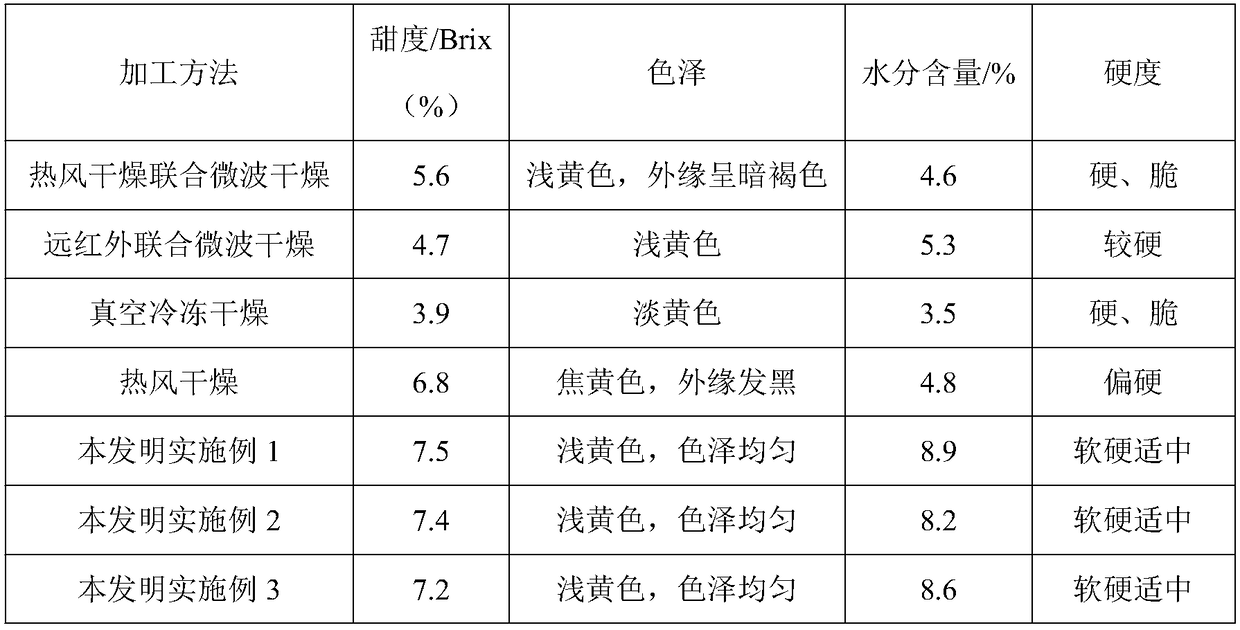

Embodiment 1

[0033] The method for preparing dried apples by means of ultrasonic osmotic dehydration combined with microwave drying comprises the following steps:

[0034] S1: Pre-treatment: Fresh, healthy and disease-free apples are washed, peeled and cored, and cut into thin slices with a thickness of 0.3 cm and a width of 2 cm;

[0035] S2: Enzyme inhibition and color protection treatment: after 15 minutes, soak the apple slices obtained in step S1 in a 0.1 mmol / L glutathione solution for 10 minutes, and then evacuate for 10 minutes at 20 kPa;

[0036] S3: Sterilization: after 12 minutes, the apple slices obtained in step S2 were sterilized by ultraviolet rays at a temperature of 25° C. and an ultraviolet wavelength of 270 nm for 15 minutes;

[0037] S4: Soaking: After 8 minutes, soak the apple thin slices obtained in step S3 according to the mass ratio of 2.5:20 to the 50% wt sucrose solution, and the soaking time is 20 minutes;

[0038] S5: Ultrasonic osmotic dehydration: the materia...

Embodiment 2

[0041] The method for preparing dried apples by means of ultrasonic osmotic dehydration combined with microwave drying comprises the following steps:

[0042] S1: Pre-treatment: Fresh, healthy and disease-free apples are washed, peeled, and cored, and cut into thin slices with a thickness of 0.5 cm and a width of 5 cm;

[0043] S2: Enzyme inhibition and color protection treatment: after 13 minutes, soak the apple slices obtained in step S1 in 0.4 mmol / L glutathione solution, perform color protection treatment for 10 minutes, and then perform evacuation treatment at 30 kPa for 5 minutes;

[0044] S3: Sterilization: After 9 minutes, the apple slices obtained in step S2 were sterilized by ultraviolet rays at a temperature of 35° C. and at a wavelength of ultraviolet rays of 290 nm for 8 minutes;

[0045] S4: Soaking: After 6 minutes, soak the apple slices obtained in step S3 at a mass ratio of 1:20 to 65% wt sucrose solution, and the soaking time is 50 minutes;

[0046] S5: ultr...

Embodiment 3

[0049]The method for preparing dried apples by means of ultrasonic osmotic dehydration combined with microwave drying comprises the following steps:

[0050] S1: Pre-treatment: fresh, healthy and disease-free apples are cut into thin slices with a thickness of 0.4 cm and a width of 3 cm after being killed, cleaned, peeled, and cored;

[0051] S2: Enzyme inhibition and color protection treatment: after 10 minutes, soak the apple slices obtained in step S1 in a glutathione solution with a concentration of 0.3 mmol / L, perform color protection treatment for 8 minutes, and then perform evacuation treatment at 25 kPa for 8 minutes;

[0052] S3: Sterilization: after 11 minutes, the apple slices obtained in step S2 were sterilized by ultraviolet rays at a temperature of 30° C. and a wavelength of ultraviolet rays of 280 nm for 12 minutes;

[0053] S4: Soaking: after 5 minutes, soak the apple slices obtained in step S3 for 60 minutes according to the mass ratio of 1:10 with 60% wt sucr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com