Anti-foaming agent for wet-process phosphoric acid production and preparation method thereof

A wet-process phosphoric acid and defoamer technology, applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc., can solve the problems of increasing the viscosity of phosphoric acid production slurry, unfavorable filtration process treatment, general defoaming effect, etc. To achieve the effect of improving diffusion capacity, improving foam suppressing capacity, and improving foam suppressing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

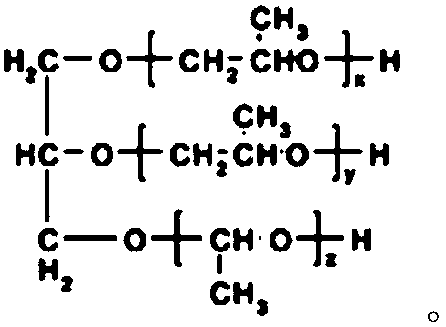

Method used

Image

Examples

Embodiment 1

[0023] Preparation of defoamer: In a closed reactor, add 6g allyl polyether (molecular weight 1200, where EO:PO=1:1), add 2g hydrogen-containing silicone oil (hydrogen content 1.6%) and 1g iso Propanol, add catalyst chloroplatinic acid, the reactor is repeatedly replaced with nitrogen and stirred, heated to 120 ℃ for 3 hours, add 3g magnesium stearate and 50g polyether A (molecular weight 2100, hydroxyl value: 50 ~ 60mgKOH / g), heat preservation and maturation reaction for 0.5 hours, and finally add 6 g of coconut oil fatty acid diethanolamide, 30 g of ethanol and 60 g of water into the reactor, continue to stir uniformly, and finally cool and discharge the defoamer I.

Embodiment 2

[0025] Preparation of defoamer: In a closed reactor, add 6g allyl polyether (molecular weight 800, where EO:PO=1:1), add 2g hydrogen-containing silicone oil (hydrogen content 1.6%) and 1g iso Propanol, add catalyst chloroplatinic acid, the reactor is repeatedly replaced with nitrogen and stirred, heated to 115°C and reacted for 2.5 hours, add 3g magnesium stearate and 50g polyether A (molecular weight 2500, hydroxyl value: 50-60mgKOH / g), heat preservation and maturation reaction for 0.5 hours, and finally add 6g coconut oil fatty acid diethanolamide, 30g ethanol and 60g water into the reactor, continue to stir uniformly, and finally cool and discharge the defoamer II.

Embodiment 3

[0027] Preparation of defoamer: In a closed reactor, add 6g of allyl polyether (molecular weight 1200, where EO:PO=1:1), add 2g of hydrogen-containing silicone oil (hydrogen content of 1.6%), and 1g Isopropanol, add catalyst chloroplatinic acid, the reactor is repeatedly replaced with nitrogen and stirred, heated to 120 ℃ for 3 hours, add 3g magnesium stearate and 50g polyether A (molecular weight 2100, hydroxyl value: 50-60mgKOH / g), heat preservation and maturation reaction for 0.5 hours, and finally 6g dioctyl sulfosuccinate sodium salt, 30g methanol and 60g water are added into the reactor, continue to stir uniformly, and finally cool the material to obtain defoamer III.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com