Preparation method for super-hydrophilic ultrafiltration membrane with photocatalytic performance

An ultra-filtration membrane and super-hydrophilic technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problem of low TiO content and water in ultrafiltration membranes Insufficient flux, small water contact angle on the membrane surface, etc., to achieve the effect of increasing anti-pollution, improving water flux, and improving water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

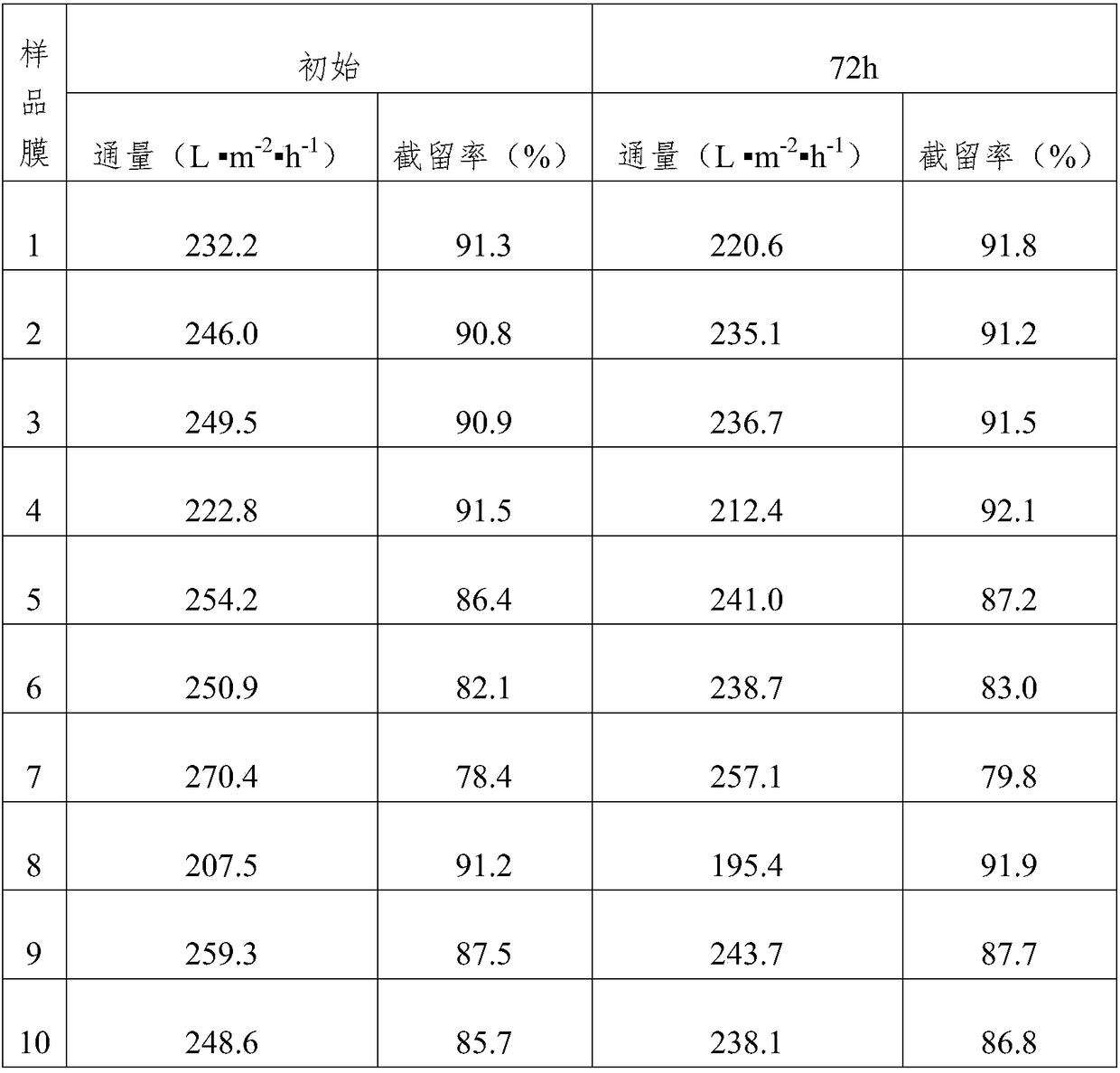

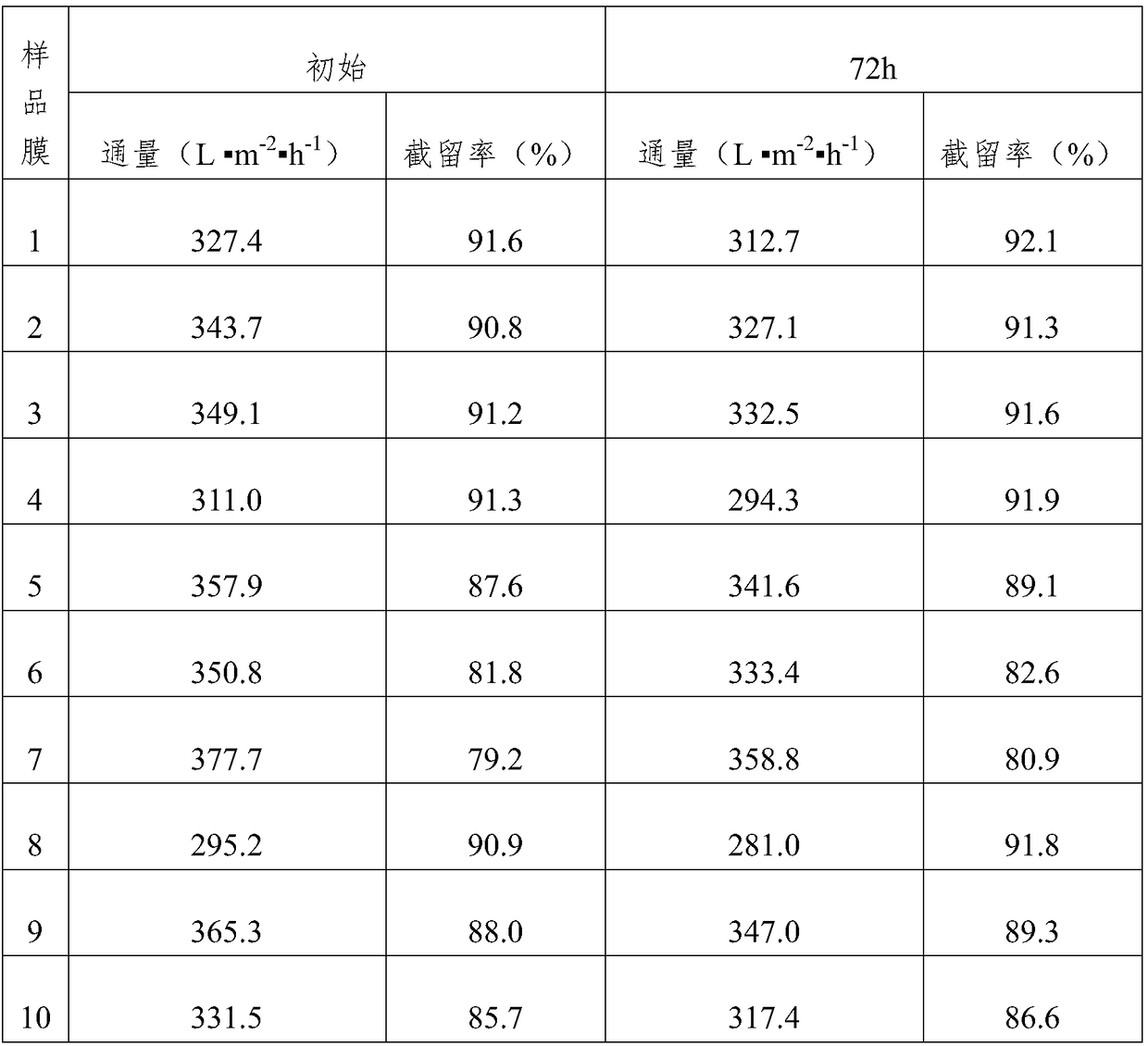

Examples

Embodiment 1

[0024] A preparation method of an ultra-hydrophilic ultrafiltration membrane with photocatalytic properties, comprising the following steps:

[0025] (1) Preparation of TiO 2 Sol solution: Add tetrabutyl titanate and glacial acetic acid to N,N-dimethylacetamide to obtain mixed solution a; add deionized water and concentrated hydrochloric acid with a mass concentration of 36% to N,N-dimethylacetamide In acetamide, a mixed solution b is obtained; under the condition of ultrasonic vibration of the mixed solution a, the mixed solution b is added to the mixed solution a, and the pH is adjusted to 4 with concentrated hydrochloric acid with a mass concentration of 36%, to obtain TiO 2 sol solution, and keep TiO 2 The sol solution is in a state of ultrasonic vibration and is ready for use; among them, the tetrabutyl titanate, glacial acetic acid, and N,N-dimethylacetamide in the mixed solution a are mixed at a volume ratio of 30:1:50, and the mixed solution b is mixed with Deionized...

Embodiment 2

[0030] A preparation method of an ultra-hydrophilic ultrafiltration membrane with photocatalytic properties, comprising the following steps:

[0031] (1) Preparation of TiO 2 Sol solution: Add tetrabutyl titanate and glacial acetic acid to N,N-dimethylacetamide to obtain mixed solution a; add deionized water and concentrated hydrochloric acid with a mass concentration of 36% to N,N-dimethylacetamide In acetamide, a mixed solution b is obtained; under the condition of ultrasonic vibration of the mixed solution a, the mixed solution b is added to the mixed solution a, and the pH is adjusted to 4 with concentrated hydrochloric acid with a mass concentration of 36%, to obtain TiO 2 sol solution, and keep TiO 2 The sol solution is in a state of ultrasonic vibration and is ready for use; among them, the tetrabutyl titanate, glacial acetic acid, and N,N-dimethylacetamide in the mixed solution a are mixed at a volume ratio of 30:1:50, and the mixed solution b is mixed with Deionized...

Embodiment 3

[0036] A preparation method of an ultra-hydrophilic ultrafiltration membrane with photocatalytic properties, comprising the following steps:

[0037] (1) Preparation of TiO 2 Sol solution: Add tetrabutyl titanate and glacial acetic acid to N,N-dimethylacetamide to obtain mixed solution a; add deionized water and concentrated hydrochloric acid with a mass concentration of 36% to N,N-dimethylacetamide In acetamide, a mixed solution b is obtained; under the condition of ultrasonic vibration of the mixed solution a, the mixed solution b is added to the mixed solution a, and the pH is adjusted to 4 with concentrated hydrochloric acid with a mass concentration of 36%, to obtain TiO 2 sol solution, and keep TiO 2 The sol solution is in a state of ultrasonic vibration and is ready for use; among them, the tetrabutyl titanate, glacial acetic acid, and N,N-dimethylacetamide in the mixed solution a are mixed at a volume ratio of 30:1:50, and the mixed solution b is mixed with Deionized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com