Platinum/platinum dichloride composite material having cubic crystal structure, and nonlinear synthesis method and application thereof

A platinum dichloride, cubic crystal technology, applied in the field of composite materials and its preparation, to achieve excellent hydrogen production performance, huge application potential and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

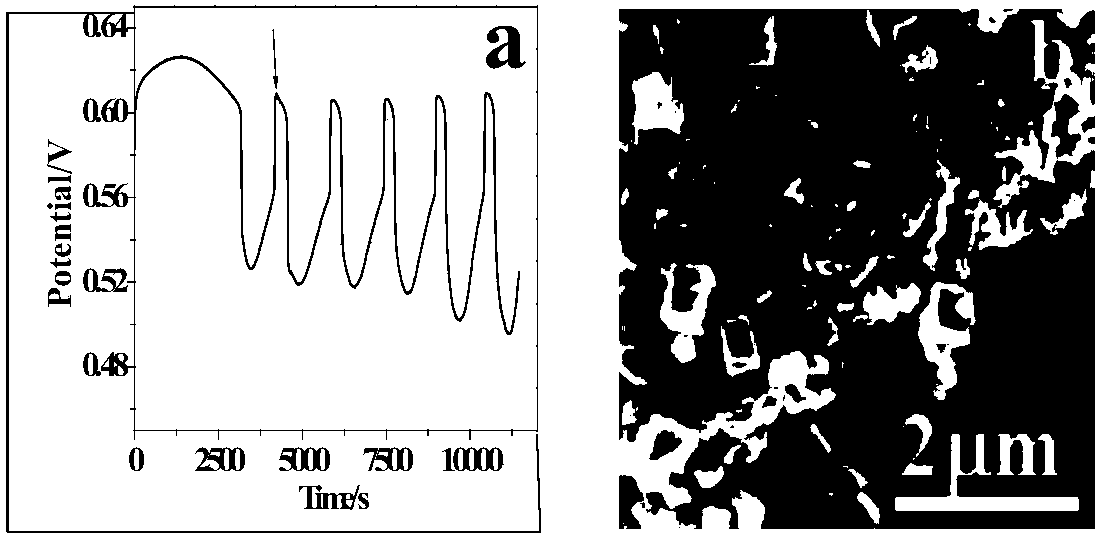

[0054] S1: Put p-nitrophenol, sodium bromate and sulfuric acid in a single water bath electrolytic cell, react at 25.0°C and atmospheric pressure, and monitor its chemical oscillation curve with the open circuit potential-time in the CHI electrochemical workstation, in which p-nitrophenol The concentration ratio of phenol, sodium bromate and sulfuric acid is 1:3:100.

[0055] S2: At the top of the first cycle of the chemical oscillation curve, add 0.0025 g of platinum dichloride ultrasonically dispersed with 5 mL of deionized water at one time, and react for 2.0 hours to obtain a reaction solution;

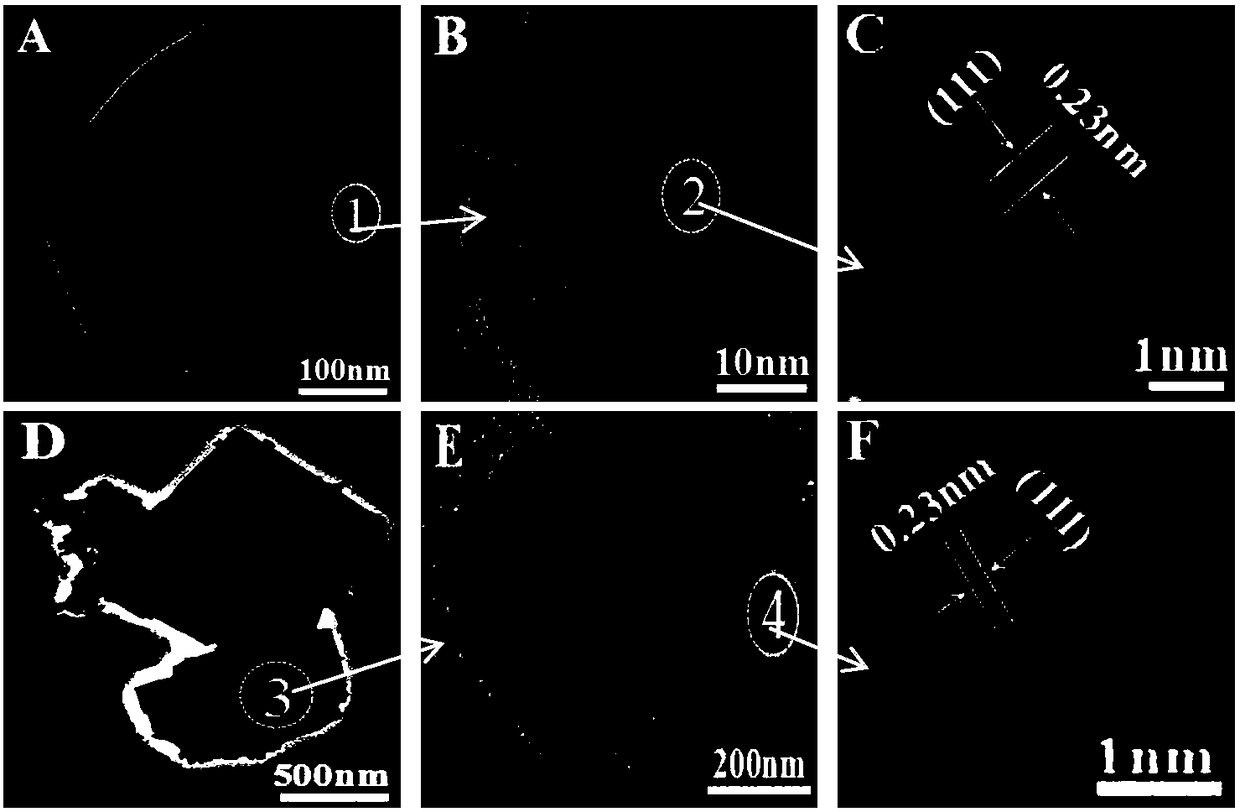

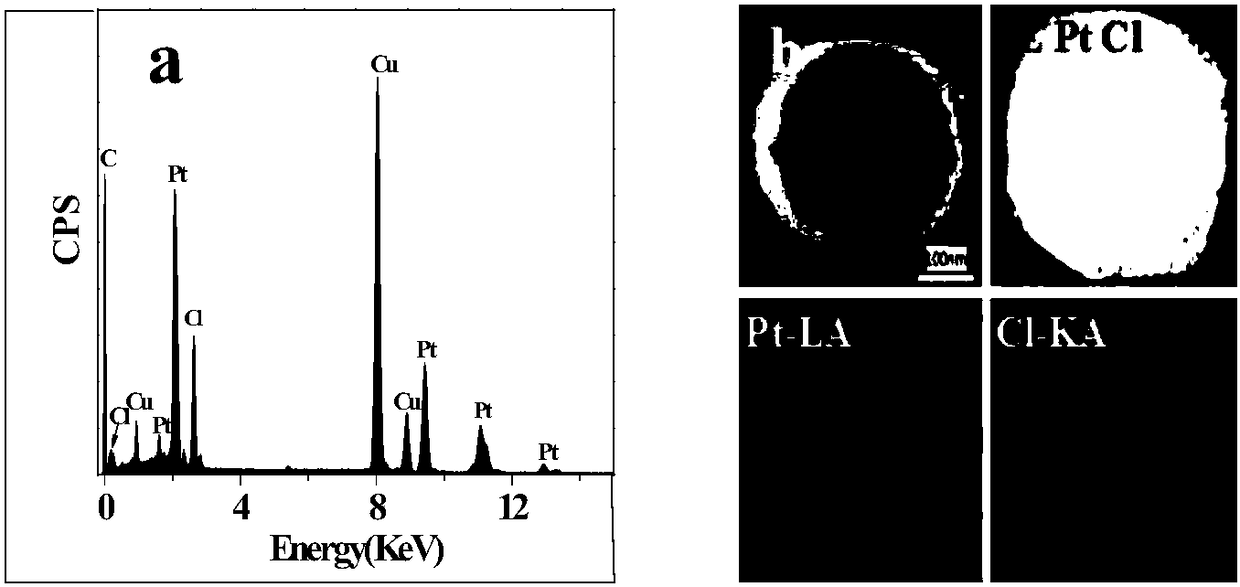

[0056] S3: Centrifuge the reaction solution at a centrifugal speed of 18000 rpm for 5 minutes, wash the obtained precipitate with deionized water, acetone, and absolute ethanol successively for 2-3 times, and then add absolute ethanol for storage to obtain the cubic Crystal structure platinum / platinum dichloride catalytic composite material, which is named as M1.

Embodiment 2-4

[0057] Embodiment 2-4: the investigation of dichloride add-on amount in the step S2

[0058] Except that the platinum dichloride consumption in step S2 is respectively replaced by (a) 0.0015g, (c) 0.0035g, (d) 0.0045g, other operations are all the same, thereby carried out embodiment 2-4 successively, They are named C2-C4 respectively.

Embodiment 5-7

[0059] Embodiment 5-7: the investigation of reaction time in step S2

[0060] Except that after adding platinum dichloride in step S2, the reaction time is replaced by (a) 0.5h, (c) 3.0h, (d) 10.0h respectively, other operations are all the same, thereby repeat operation embodiment 1, thereby Embodiments 5-7 were carried out sequentially, and the obtained composite materials were named C5-C7 in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com