Composite pressing block type phase change heat storage gas-solid hydrogen storage reactor

A technology of phase change heat storage and reactor, which is applied in chemical/physical/physicochemical fixed reactor, reactant parameter control, hydrogen, etc. It can solve the problems of easily damaged heat pipe, inconvenient to carry, bulky, etc. Achieve the effects of easy replacement, light weight, and simplified device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

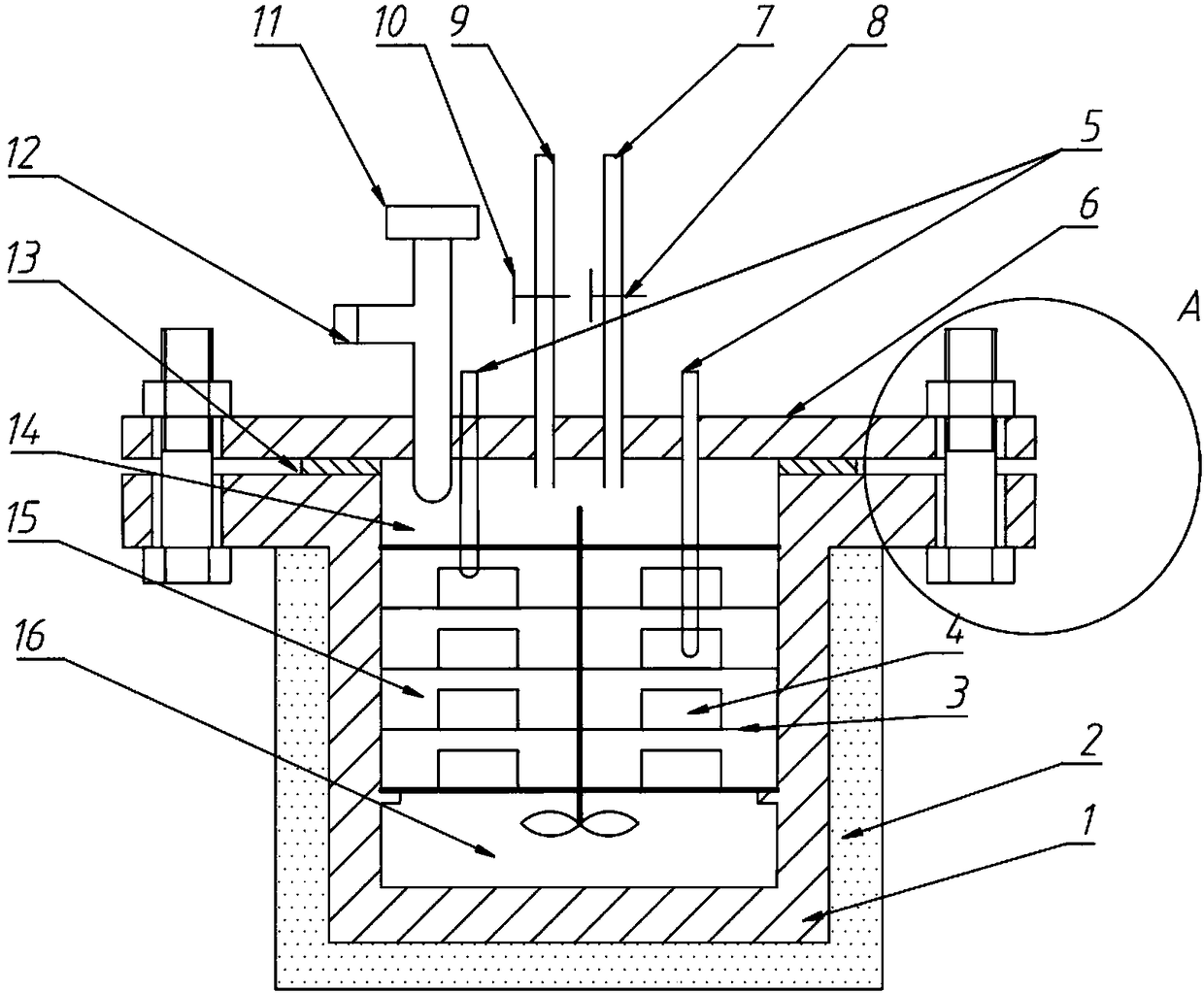

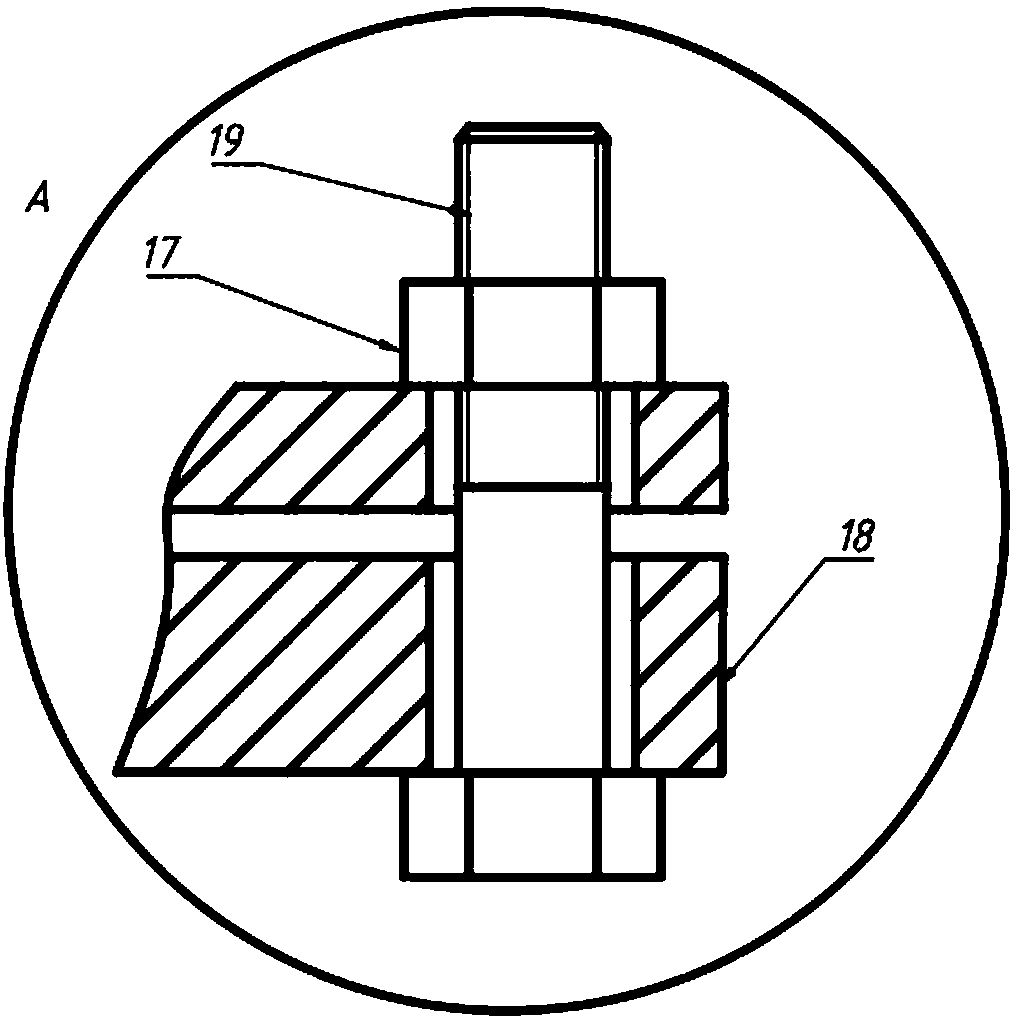

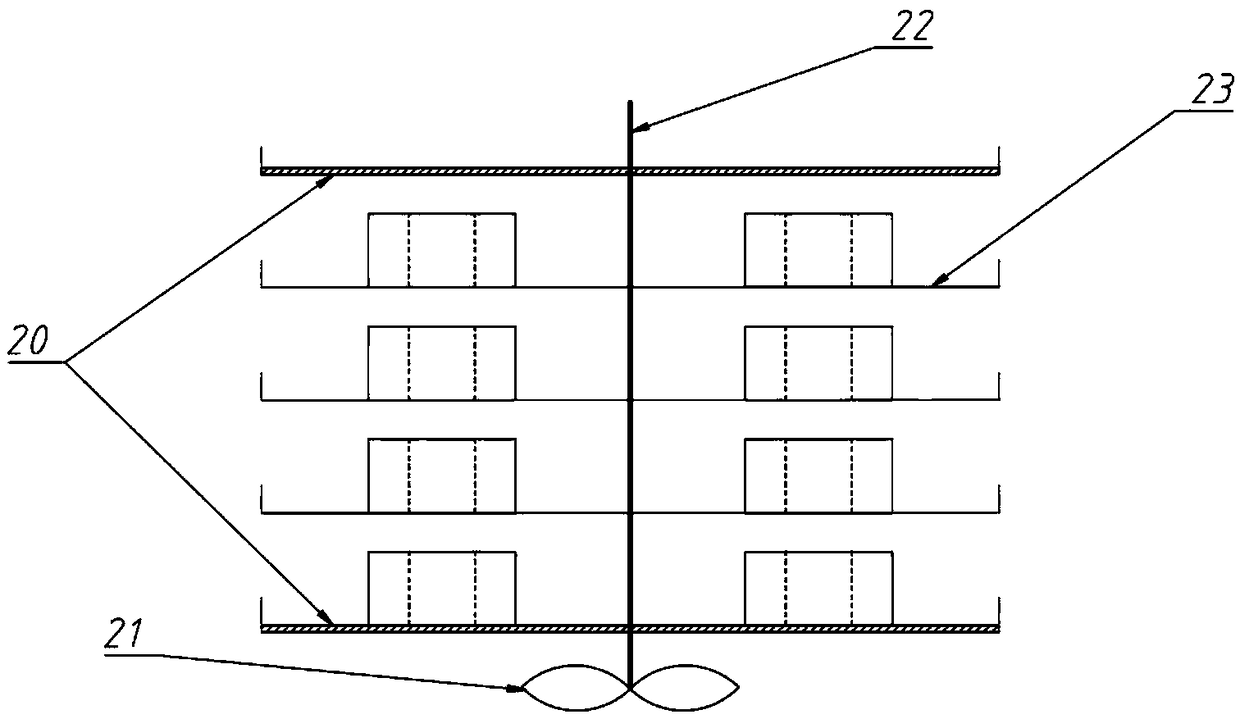

[0034] The invention relates to a gas-solid hydrogen storage reactor of composite briquette type phase change heat storage, and the overall structure of the reactor is a cylindrical shell. The outside of the reactor is covered with an insulating layer to prevent heat loss. Inside the reactor is a hierarchical porous tray that is easy to install and disassemble. The cavity between the top of the tray and the top of the reactor forms a gas phase buffer tank, and the bottom of the tray is fixed with stirring blades. It constitutes an air flow agitator, and multiple layers of concentric briquettes composed of hydrogen storage materials and phase change materials are placed in the hierarchical porous tray; the top of the reactor is sealed with a flange, which is used as the inlet and outlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com