Reaction type copolymerized flame-retardant furan-based polyester and preparation method thereof

A furan-based polyester, copolymerized flame-retardant technology, applied in the field of polyester and its preparation, can solve the problem of furandicarboxylic acid-based polyester being flammable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

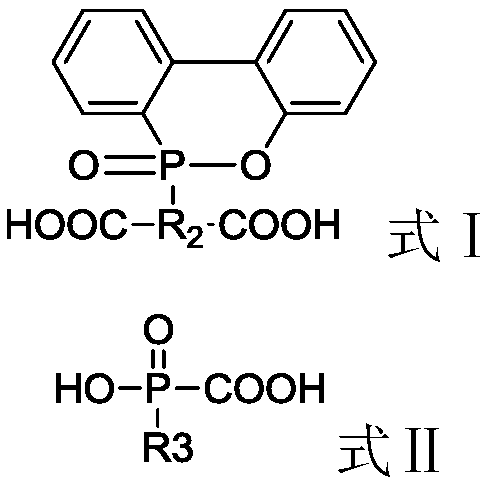

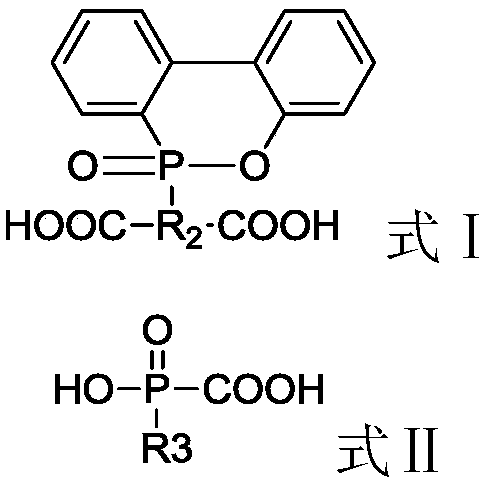

[0042] The present invention also provides a preparation method of reactive copolymerized flame-retardant furyl polyester, the method comprising:

[0043] Step 1: React the reactive phosphorus-containing flame retardant, diol and catalyst under nitrogen atmosphere at 150-200°C for 0.5-3 hours, preferably at 150-160°C for 1-2 hours, to obtain a prepolymerization solution;

[0044] Step 2: Under a nitrogen atmosphere, add furandicarboxylic acid or dimethyl furandicarboxylate to the prepolymerization solution obtained in step 1, react at 180-280°C for 0.5-3h, and react at 210-250°C for 2-3h to obtain a prepolymer ;

[0045] Step 3: Vacuumize the reaction system to -0.06~0.1MPa, preferably 0.09~0.1MPa, react the prepolymer obtained in step 2 at 180~280°C for 2~8h, and react at 220~250°C for 6~8h to obtain the reactive type Copolymerized flame retardant furyl polyester.

[0046] Because the phosphorus-containing dibasic acid is unstable at high temperature, the method of esterify...

Embodiment 1

[0049] (1) 20 parts of flame retardant 2-carboxyethylphenyl hypophosphorous acid, 200 parts of 1,6-hexanediol, 0.1 part of butyl titanate, under the protection of nitrogen, stirred at 150oC for 2 hours to obtain a flame retardant Prepolymer;

[0050] (2) Add 100 parts of furandicarboxylic acid into the above-mentioned flame retardant prepolymer, under nitrogen atmosphere, stir and react at 235oC for 3h to generate the prepolymer;

[0051] (3) Then evacuate to -0.090MPa, and stir the above prepolymer at 235oC for 8 hours to generate flame-retardant copolyfuryl polyester.

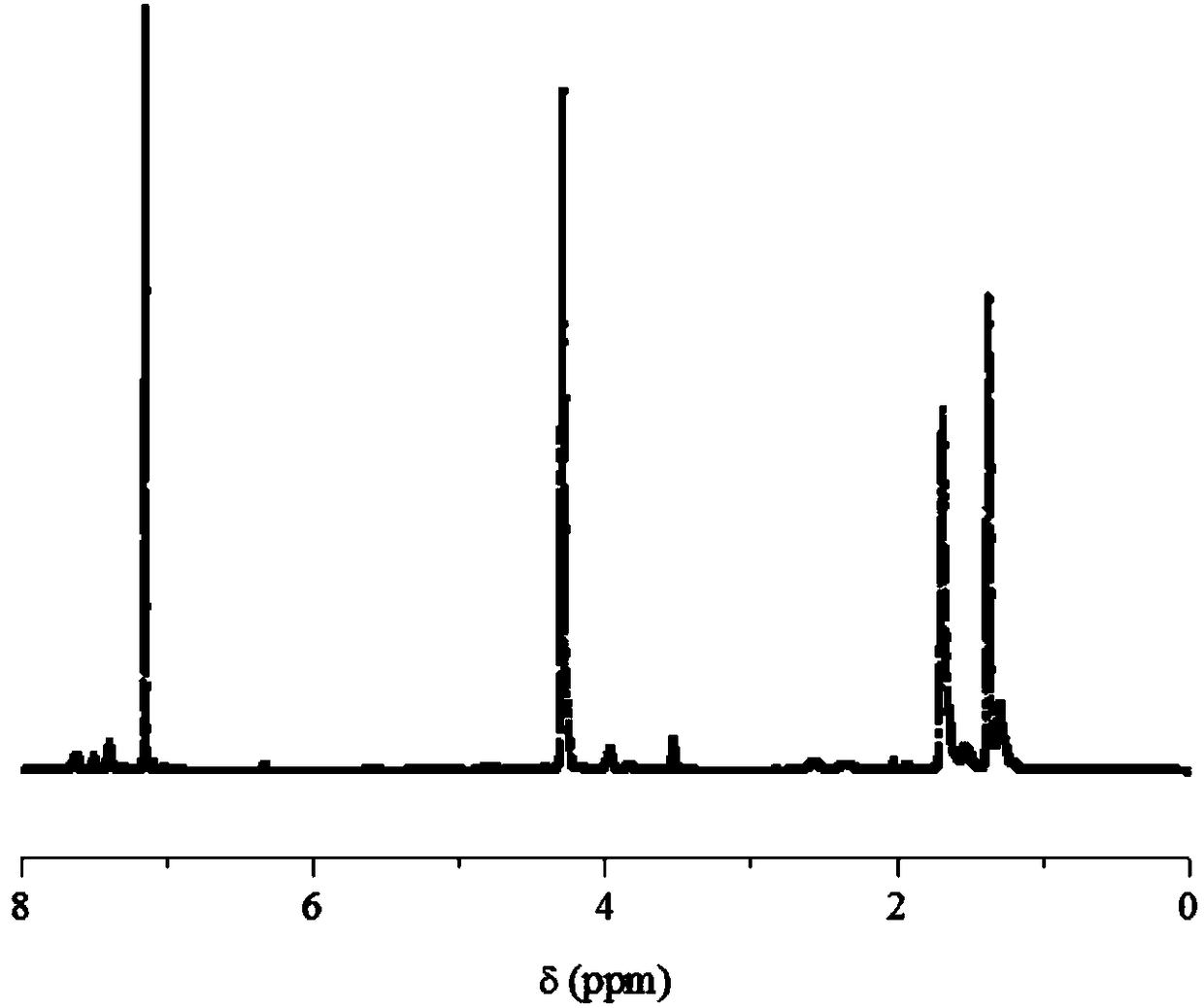

[0052] figure 1 It is the H NMR spectrum of the copolyfuryl polyester prepared in Example 1 of the present invention.

[0053] figure 1 It shows that the present invention has successfully prepared flame-retardant copolyfuryl polyester.

[0054] The experimental results show that: the limiting oxygen index of the flame retardant copolyester prepared in Example 1 is 28, and the vertical burning test level ...

Embodiment 2

[0056] A preparation method of flame-retardant copolymerized furyl polyester, specifically comprising the following steps:

[0057](1) 25 parts of flame retardant 2-carboxyethylphenylphosphinic acid, 150 parts of 1,3-propanediol, 0.05 part of stannous octoate, under the protection of nitrogen, stirred at 160oC for 1 hour to obtain a flame retardant prepolymer ;

[0058] (2) Add 100 parts of furandicarboxylic acid into the above-mentioned flame retardant prepolymer, under nitrogen atmosphere, stir and react at 250oC for 2h to generate the prepolymer;

[0059] (3) Then evacuate to -0.095MPa, and stir the above-mentioned prepolymer at 250°C for 6 hours to generate flame-retardant co-polyfuryl polyester.

[0060] The experimental results show that the limiting oxygen index of the flame-retardant copolyester prepared in Example 2 is 29, and the vertical burning test grade reaches UL94V-2 grade.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com