System and technology for disposing and recycling transferring waste barrels by utilizing pyrolysis gasification furnace

A pyrolysis gasification and pyrolysis technology, applied in the field of gasifier incineration, can solve the problems of improper handling and incomplete disposal of transfer waste barrels, which is beneficial to control and operation, avoids positive pressure tempering, and increases contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

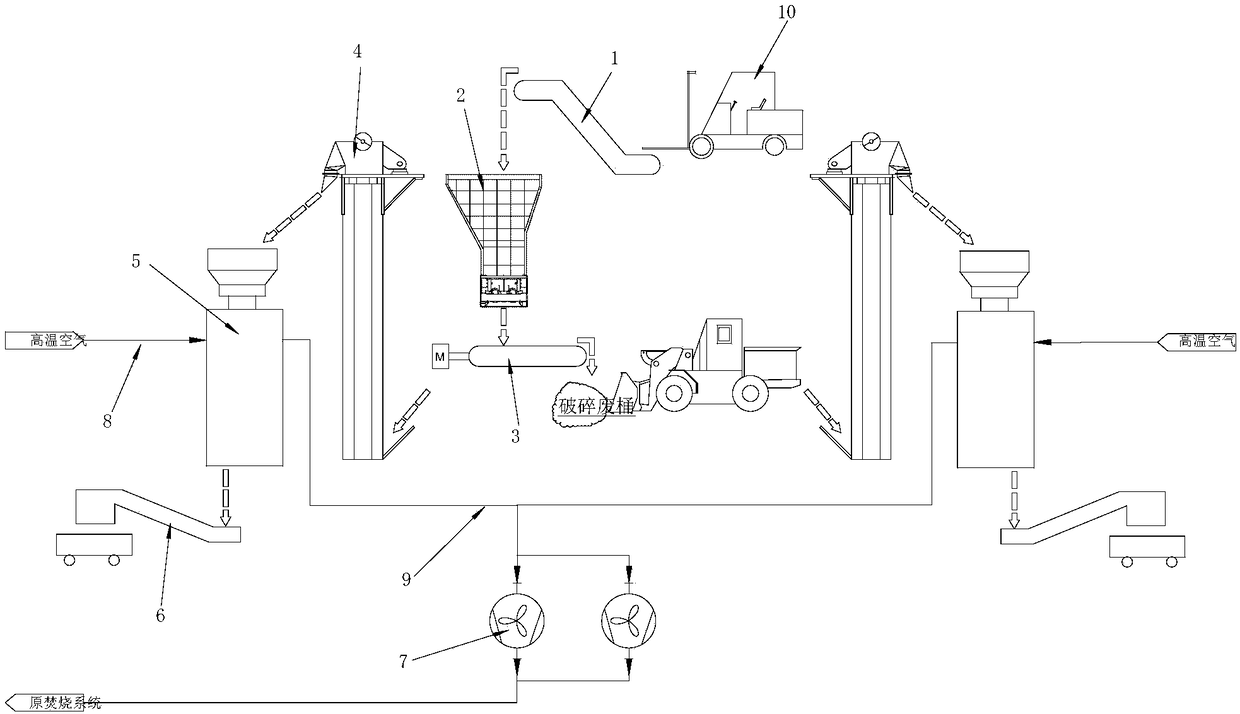

[0041] Such as figure 1 As shown, the present invention provides a waste barrel treatment and recycling system using a pyrolysis gasifier, which includes a waste barrel pretreatment system, a feeding system, a pyrolysis system, a slag removal system and an original incineration system.

[0042]The waste barrel pretreatment system includes a chain plate feeder 1 and an iron barrel crusher 2, the feeding system includes a belt discharge machine 3 and a bucket elevator 4, and the pyrolysis system includes a pyrolysis gasifier 5. The slag discharge system includes an iron sheet conveyor 6, and the chain plate feeder 1 is set directly above the feed port of the iron barrel crusher 2, and transports waste barrels to the iron barrel crusher 2 for crushing; The iron pieces crushed by the iron bucket crusher 2 are sent to the bucket elevator 4 through the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com