Cathode grid assembly of cold cathode X-ray tube for screen printing process and manufacturing method thereof

A technology of X-ray tube and silk screen printing process, which is applied in the direction of X-ray tube electrodes, X-ray tube parts, X-ray tubes, etc., which can solve the problems of easily damaged cathode materials, difficulties in fixing and aligning, and inability to ensure the distance between cathode grids and other problems to achieve the effect of solving errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions and beneficial effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

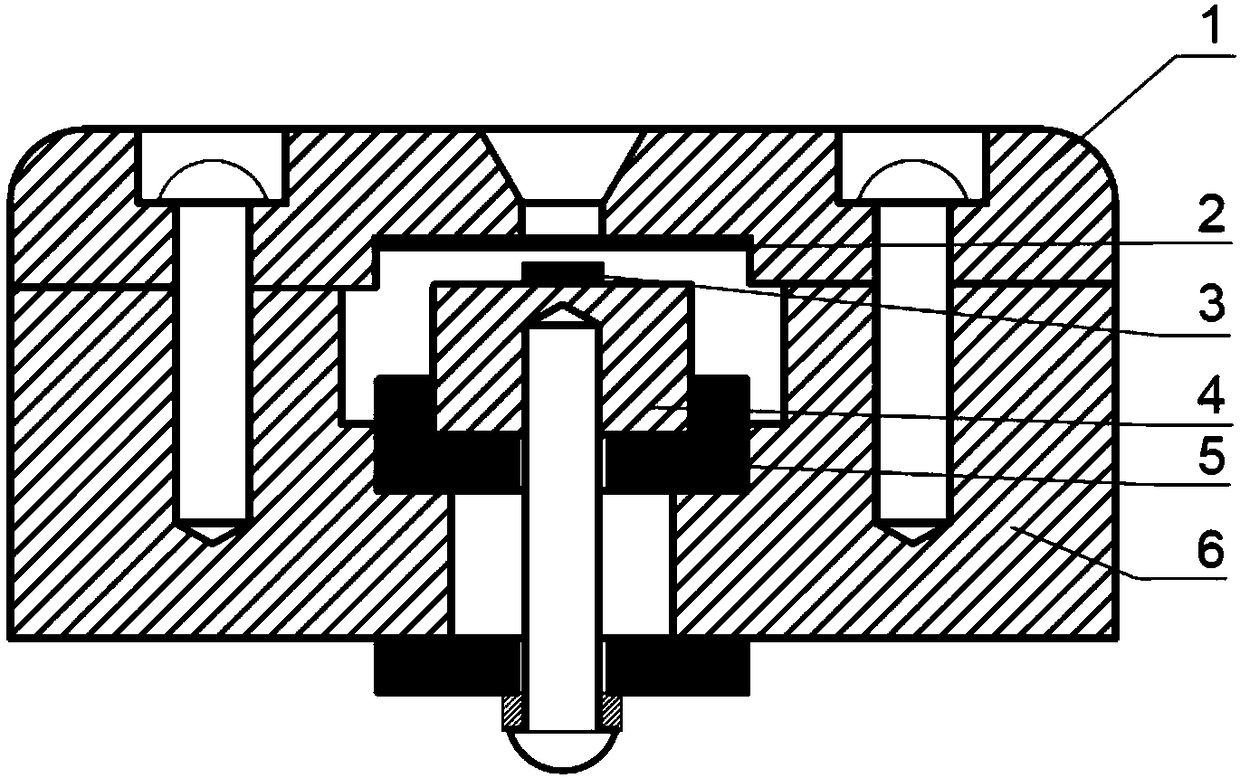

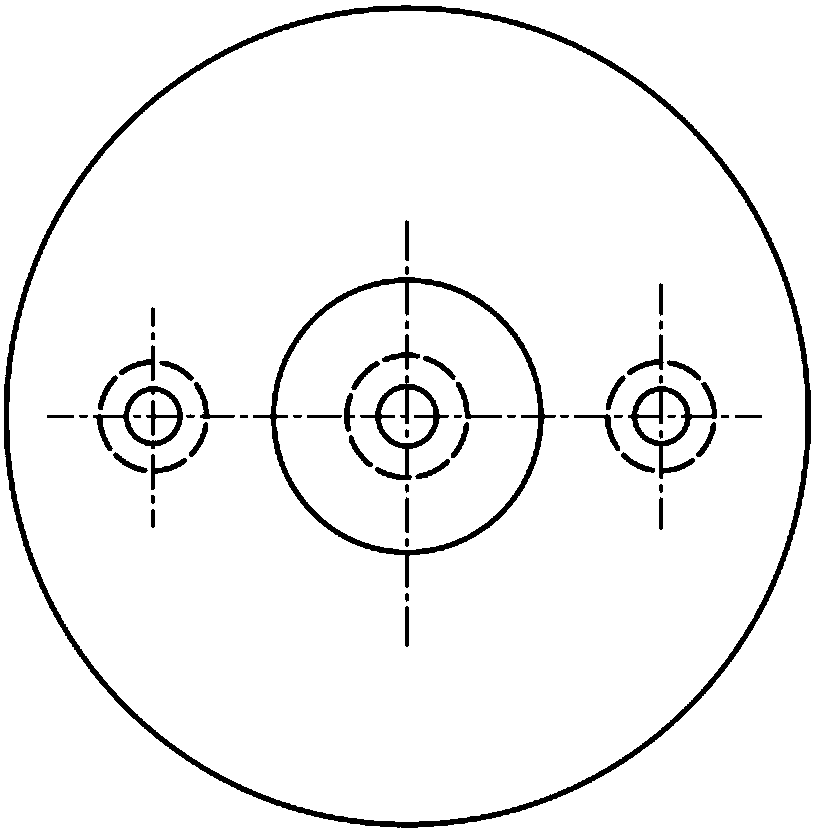

[0029] Such as Figure 1 to Figure 3 As shown, the present invention provides a cold cathode X-ray tube negative grid assembly suitable for silk screen printing, including grid base 6, cathode base 4, ceramic gasket 5, cold cathode 3, grid 2 and engraved with grooves The grid flange 1 is assembled, wherein the grid base 6, the cathode base 4 and the grid flange 1 are all stainless steel and other homogeneous metal parts suitable for vacuum, and the grid 2 is made of stainless steel or molybdenum.

[0030] Wherein, the thickness of the cold cathode 3 is 10-30 microns, and the diameter is less than 1 mm.

[0031] Wherein, the thickness of the grid 2 is 50 microns.

[0032] Wherein, the groove depth of the grid flange 1 is 0.3-0.5 mm.

[0033] The present invention also provides a method for manufacturing the above-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com