3D printed vaginal drug delivery device

A vaginal drug delivery and 3D printing technology, applied in the field of medical products, can solve the problem of no vaginal device, achieve good application prospects and market value, save the mold making process, and be convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

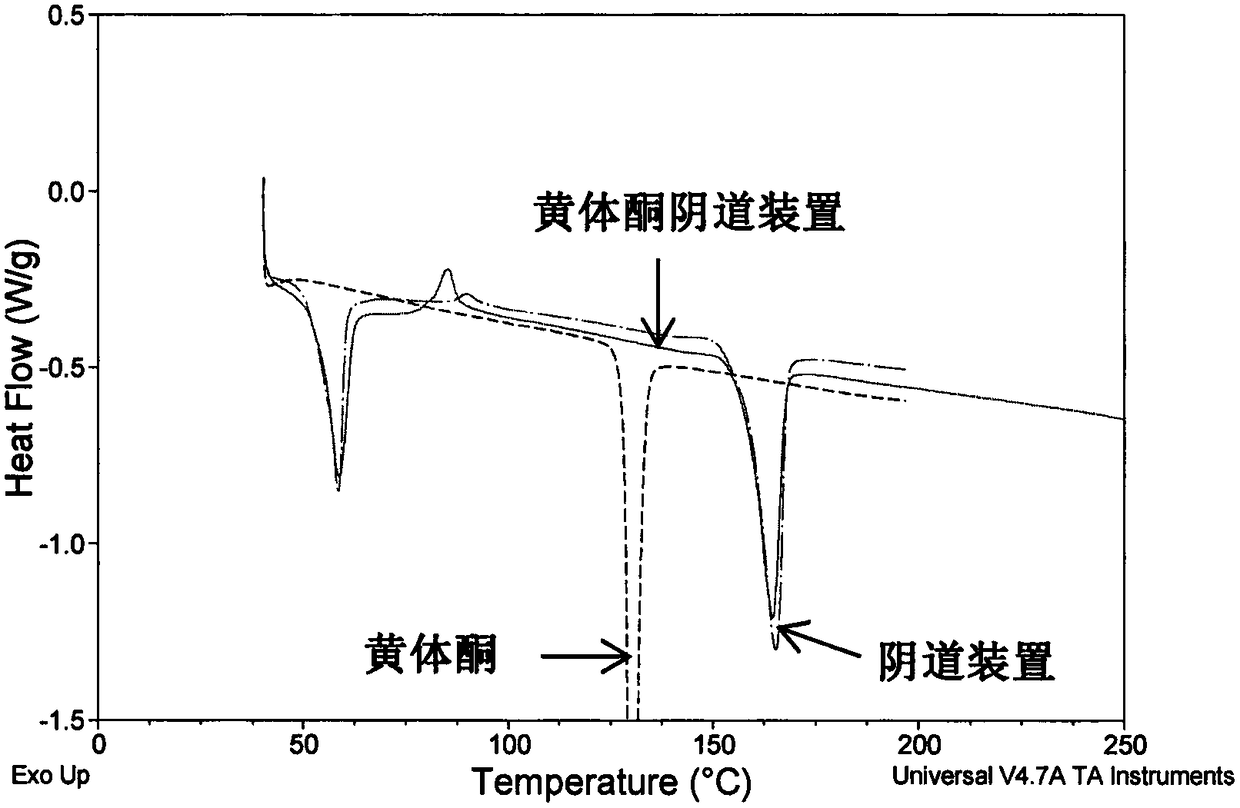

[0029] Example 1. 3D printed progesterone vaginal device

[0030] 1. Materials

[0031] Progesterone, purchased from Jiangsu Yuanda Xinyi Pharmaceutical Co., Ltd., batch number: 20170216; polyethylene glycol-4000, purchased from Tianjin Tiantai Fine Chemical Co., Ltd., batch number: 19920705; polylactic acid (PLA), model: 2002D, purchased from American NatureWorks company, batch number: 20160924; Polycaprolactone, model: 6800, purchased from American Solvay Company, batch number: 20160722; Tween-80, purchased from Shanghai Dazhong Pharmaceutical Factory, batch number: 2011923; Hot melt extruder, Model: WellzoomB, purchased from Shenzhen Mistar Technology Co., Ltd.; 3D shape design software, AutoCAD 2007; fused deposition 3D printer, model: CF-12410B, purchased from Hong Kong Renaissance Technology Group.

[0032] 2. Method results

[0033] Weigh 1.5g of progesterone and sieve it, stir and mix with 3g of crushed polyethylene glycol-4000, then put it into a beaker, heat and st...

Embodiment 2

[0036] Example 2. 3D printed estradiol vaginal device

[0037] 1. Materials

[0038] Estradiol, purchased from Guangzhou Yangye Biotechnology Co., Ltd., batch number: 20160524; polyethylene glycol-4000, purchased from Tianjin Tiantai Fine Chemical Co., Ltd., batch number: 19920705; polylactic acid (PLA), model: 2002D, purchased From NatureWorks, USA, batch number: 20160924; polycaprolactone, model: 6800, purchased from Solvay, USA, batch number: 20160722; Tween-80, purchased from Shanghai Dazhong Pharmaceutical Factory, batch number: 2011923; hot melt extruder , model: WellzoomB, purchased from Shenzhen Mistar Technology Co., Ltd.; 3D shape design software, AutoCAD 2007; fused deposition 3D printer, model: CF-12410B, purchased from Hong Kong Renaissance Technology Group.

[0039] 2. Method results

[0040] Take 0.6g of estradiol and 2g of polyethylene glycol-4000 in a small beaker and mix evenly with a vortex mixer; stir it with a glass rod in a water bath at 70°C to dissolv...

Embodiment 3

[0043] Example 3. 3D printed oxytetracycline vaginal device

[0044] Oxytetracycline was purchased from Henan Tianfu Chemical Co., Ltd. Other materials are the same as in Example 1.

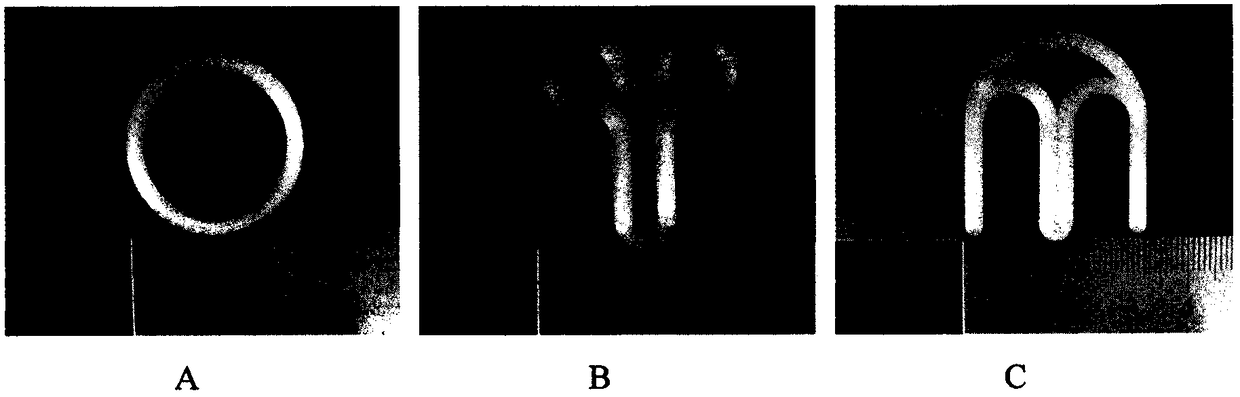

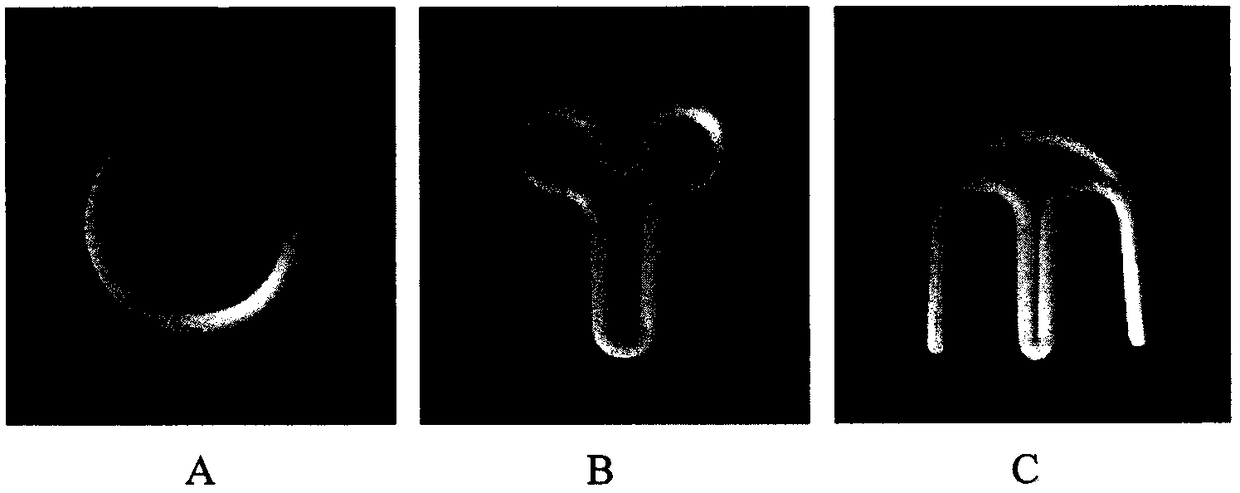

[0045] Take oxytetracycline 0.5g and polyethylene glycol-4000 2.0g in a small beaker and mix evenly; stir in a 70°C water bath to melt, then pour it on a stainless steel plate and let it spread naturally. After solidification, cut Form into granules with a diameter of about 3 mm, and set aside; take 0.8 g of Tween-8, 13.0 g of polylactic acid, 3.0 g of polycaprolactone and the above solid dispersion, mix them evenly, put them in the hopper of a desktop extruder, and melt them at 180 ° C Blend and extrude to obtain extruded strips, use the obtained extruded strips to print O-shaped, Y-shaped, M-shaped, U-shaped, and twist-shaped oxytetracycline vaginal devices with a fused deposition 3D printer under heating conditions of 180°C .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com