Iron oxide red pigment two-step oxidation process waste gas treatment method

An oxidation process, iron oxide red technology, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problem that exhaust gas treatment devices and methods cannot meet the emission requirements, and achieve the goal of improving absorption efficiency and oxidation degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

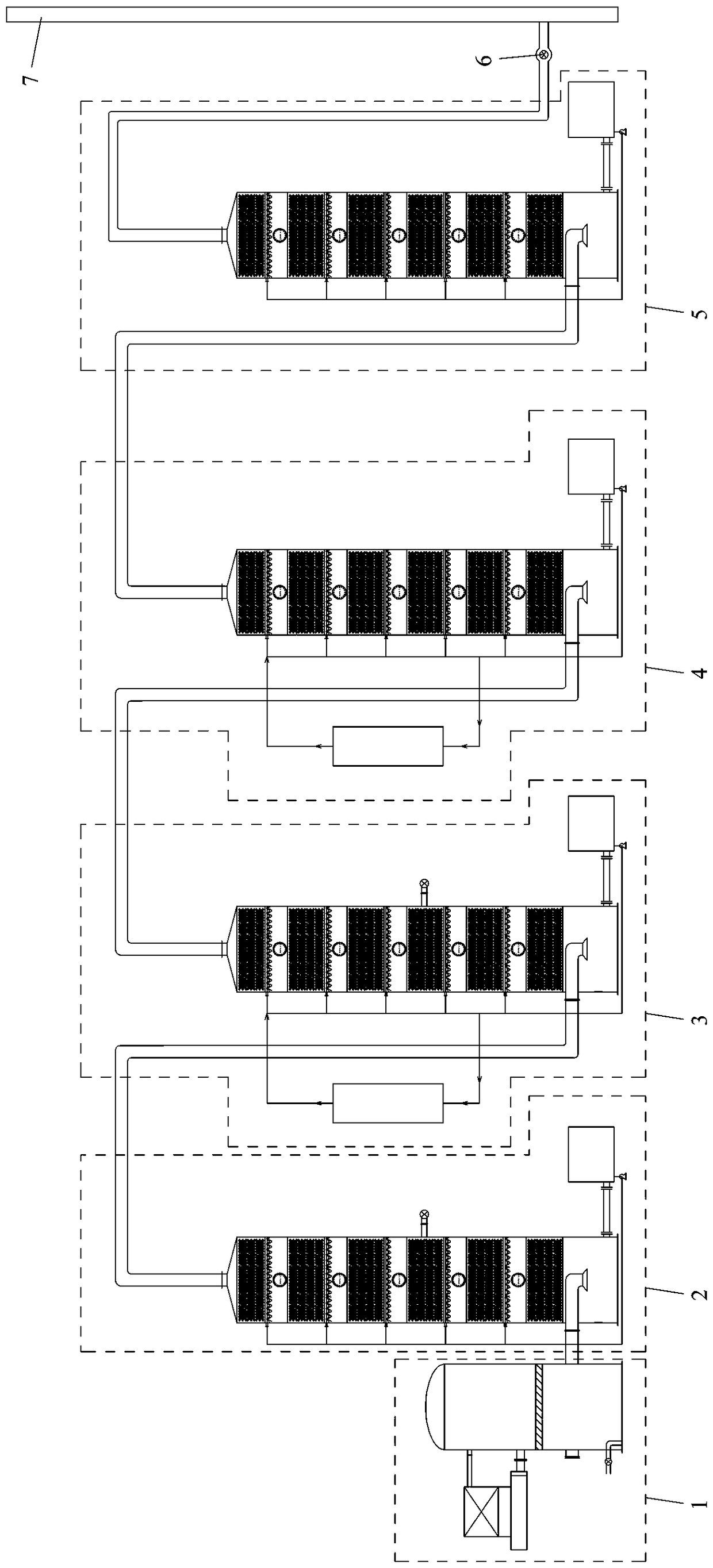

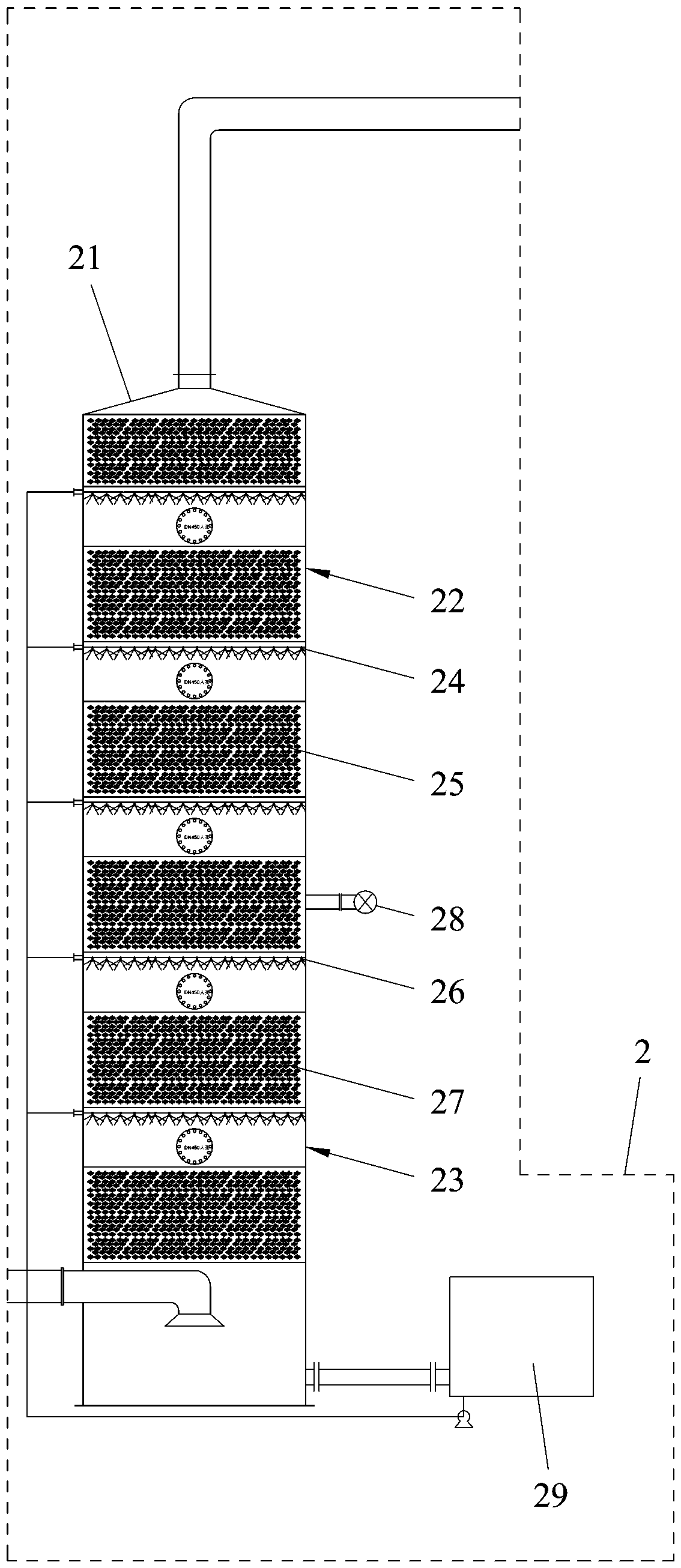

[0043] Embodiment one: the exhaust gas produced by the two-step oxidation process of iron oxide red pigment (also can be referred to as NO X The main components of exhaust gas) include steam, air, nitrogen oxides and trace iron red particles. An iron oxide red pigment two-step oxidation process waste gas treatment device for treating the above waste gas is as attached figure 1 As shown, it includes a tubular heat exchanger 1, a concentrated nitric acid oxidation tower 2, a dilute nitric acid absorption tower 3, a sodium hydroxide absorption tower 4, and a urea solution absorption tower 5 connected in sequence.

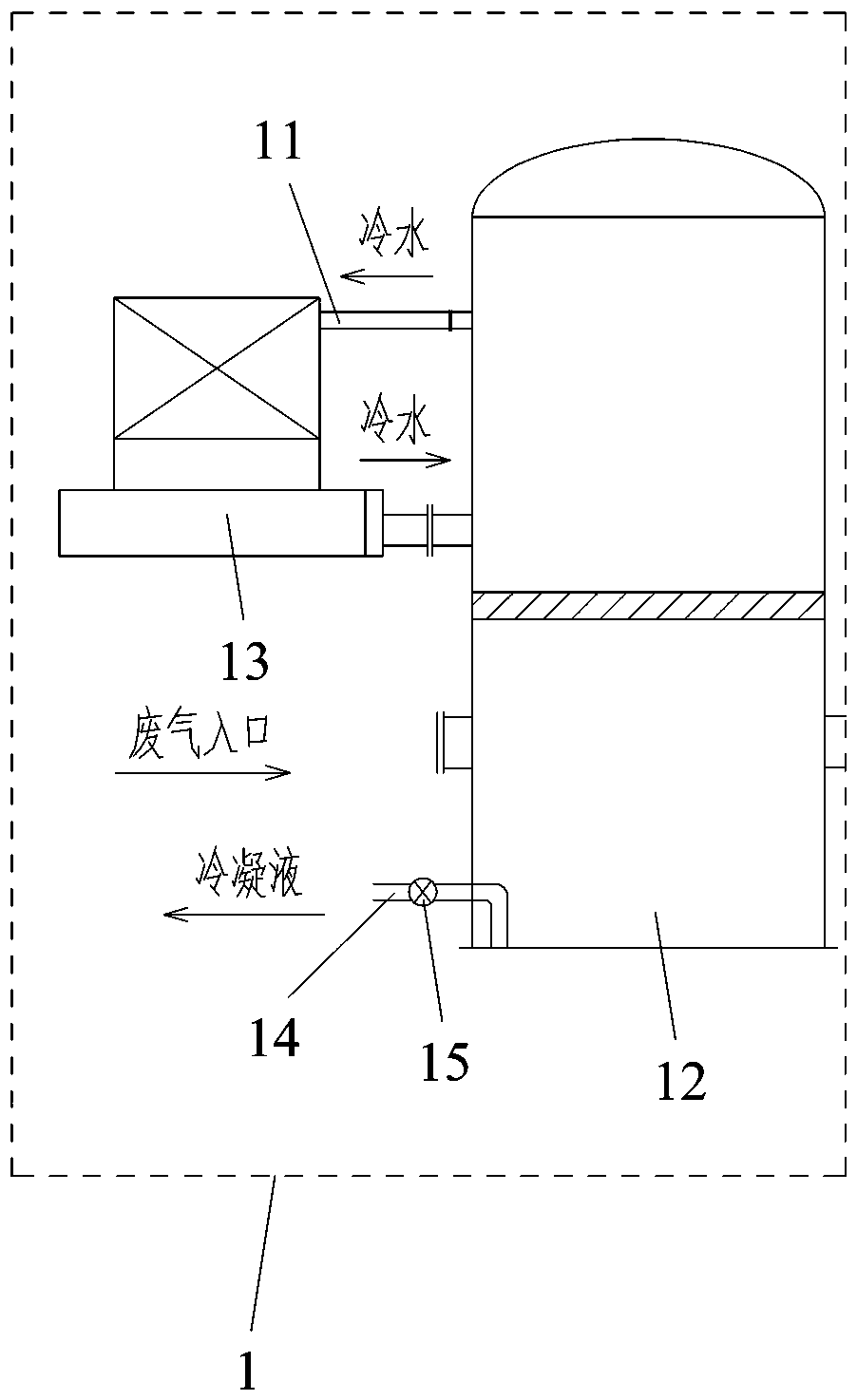

[0044] as attached figure 2As shown, the tubular heat exchanger 1 is connected to the device for the two-step oxidation process, that is, the oxidation barrel, and input the exhaust gas to be treated, which is used to remove the steam and iron red particles in the exhaust gas by heat exchange and cooling to generate a level exhaust gas. The tubular heat exchanger 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com