Diamond coating drill bit and preparation method thereof

A diamond coating, diamond technology, applied in metal material coating process, coating, twist drill and other directions, can solve the problems of poor wear resistance, large chip discharge resistance, long service life, etc., to achieve wear resistance and chip discharge. Excellent performance, improve work efficiency, improve the effect of grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

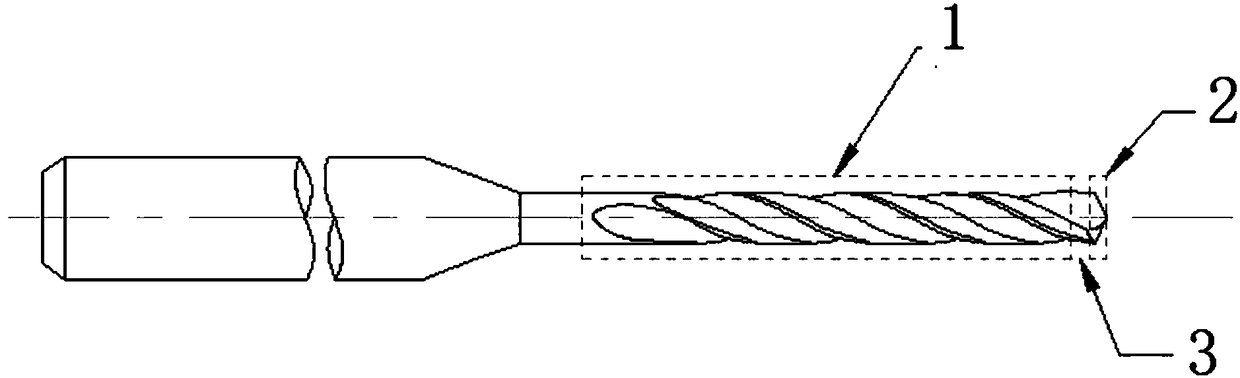

[0054] This embodiment provides a diamond coated drill bit, such as figure 1 As shown, the drill bit includes a drill body 1 and a drill tip 2, the drill body 1 is coated with a nanocrystalline diamond coating, and the coating thickness is 10 μm; the drill tip 2 is coated with a microcrystalline diamond coating, and the coating is coated with a nanocrystalline diamond coating. The thickness of the layer is 10.5 μm; there is a transition zone 3 whose length is 1.2 times the diameter of the drill bit between the drill body 1 and the drill tip 2, and the grain size of the diamond coating coated on the transition zone 3 is between that of the diamond coating coated on the drill body 1. Between the nanocrystals and the microcrystals coated with the drill tip 2, the average thickness of the coating is 10.2 μm; the base of the drill bit is WC-Co alloy.

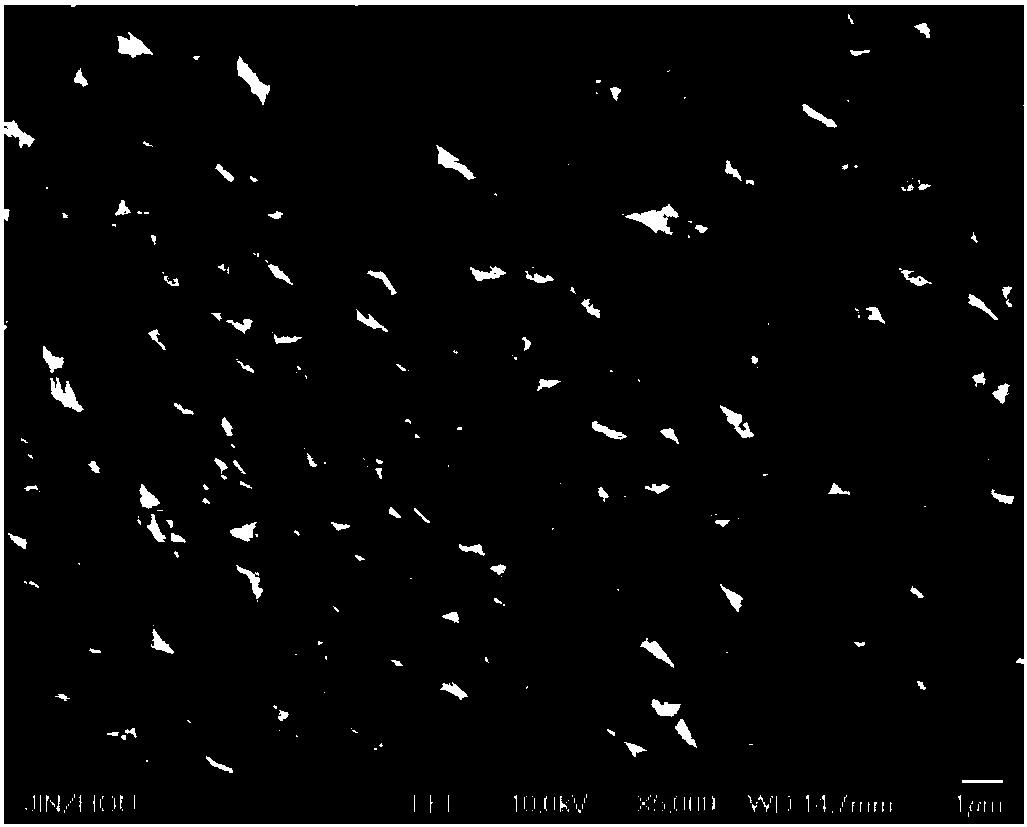

[0055] Carry out SEM scanning respectively to the drill body and drill point of the drill bit that present embodiment obtains, as ...

Embodiment 2

[0060] The present embodiment provides a diamond-coated drill bit, the drill bit comprises a drill body 1 and a drill tip 2, the drill body 1 is coated with a nanocrystalline diamond coating with an average grain size of about 20-150nm, and the thickness of the coating is The drill tip 2 is coated with a microcrystalline diamond coating with an average grain size of about 1-2 μm, and the coating thickness is 20 μm; the length between the drill body 1 and the drill tip 2 is 1.5 mm in diameter of the drill bit. times the transition zone 3, the grain size of the diamond coating coated in the transition zone 3 is between the nano crystals coated on the drill body 1 and the micro crystals coated on the drill tip 2, and the average thickness of the coating is 19.2 μm; The base body of the drill bit is WC-Co alloy.

[0061] The method for preparing a diamond-coated drill bit is the same as in Example 1. By adjusting the substrate temperature and deposition time, a nanocrystalline dia...

Embodiment 3

[0063] The present embodiment provides a diamond-coated drill bit, the drill bit includes a drill body 1 and a drill tip 2, the drill body 1 is coated with a nanocrystalline diamond coating with an average grain size of about 20-200nm, and the thickness of the coating is 8 μm; the drill bit 2 is coated with a microcrystalline diamond coating with an average grain size of about 0.5-3 μm, and the coating thickness is 12 μm; the length between the drill body 1 and the drill tip 2 is 1 times the diameter of the drill bit The transition zone 3, the grain size of the diamond coating coated in the transition zone 3 is between the nano crystals coated on the drill body 1 and the micro crystals coated on the drill tip 2, and the average thickness of the coating is 10.5 μm; The base of the drill bit is WC-Co alloy.

[0064] The method for preparing the diamond-coated drill bit is the same as in Example 1. By adjusting the substrate temperature and deposition time, a nanocrystalline diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com