Diamond anvil cell sample temperature measuring method

A technology of diamond anvil and measurement method, which is applied in thermometers, measuring devices, measuring heat, etc., can solve the problems of unfavorable arrangement of thermocouples and small size, and achieve the effects of easy implementation, simple method and good experimental repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

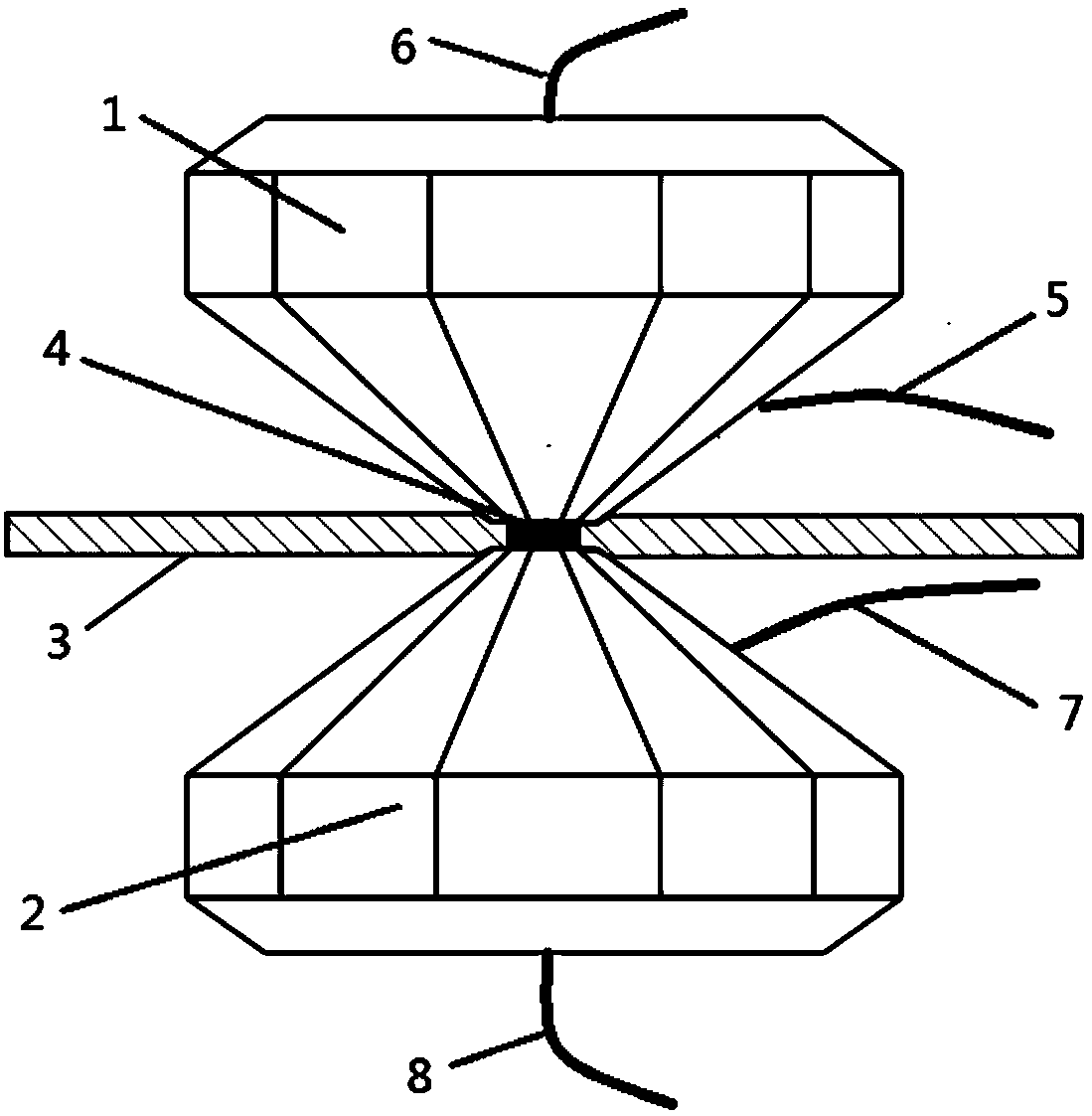

[0026] Embodiment 1 is combined with attached figure 1 The device structure and assembly of the present invention will be described.

[0027] figure 1Among them, 1 is the upper diamond anvil, 2 is the lower diamond anvil, 5 is the thermocouple on the upper side, 6 is the thermocouple on the upper bottom, 7 is the thermocouple on the lower side, and 8 is the thermocouple on the lower bottom. The temperature measuring points of the thermocouples can be fixed sequentially at the center of the bottom surface of the two diamond anvils and 1 / 2 of the side edges of the diamond anvils by using silver paste. The four thermocouples are K-type thermocouples with a diameter of 100 μm. The cold ends of the thermocouples are connected to the Keithley2700 data acquisition instrument. The temperature of the 4 temperature measuring points at the center and 1 / 2 of the side edge are measured simultaneously. The anvil surface of the upper diamond anvil 1 and the anvil surface of the lower diam...

Embodiment 2

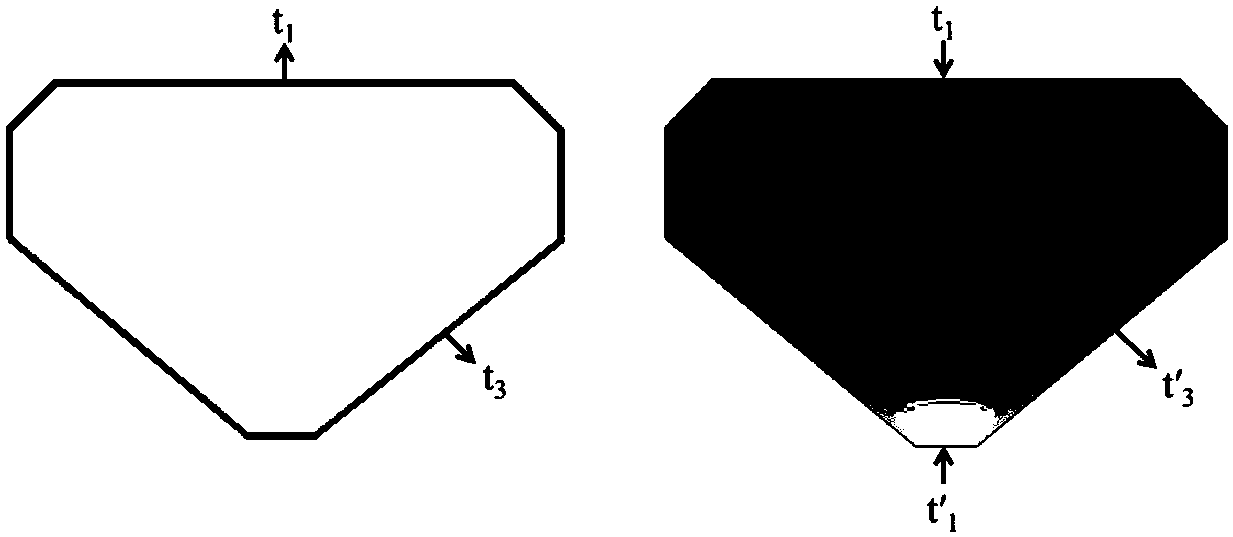

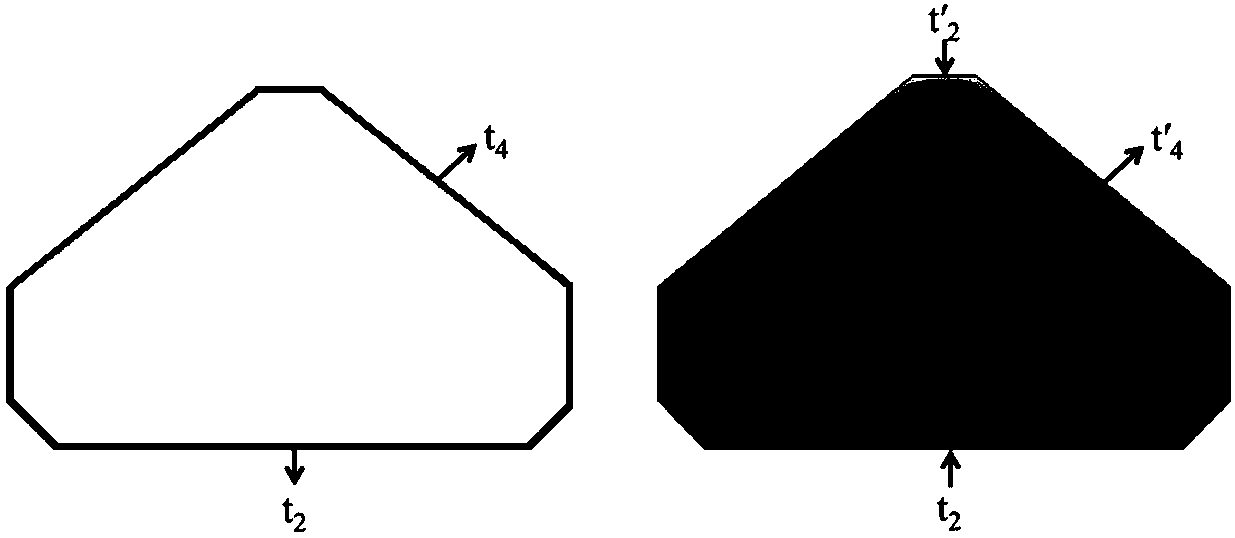

[0034] Embodiment 2 combines attached figure 2 , 3 , 4 Explain the measurement principle of the sample temperature.

[0035] figure 2 , 3 In the experiment, through the thermocouples (upper bottom thermocouple 6, lower bottom thermocouple 8, upper edge thermocouple 5, lower Edge thermocouple 7) read the temperature value t of the corresponding temperature measuring point respectively 1 , t 2 , t 3 , t 4 , the center temperature t of the bottom surface of the upper and lower diamond anvils 1 , t 2 and the input temperature t′ of the upper and lower diamond anvil surfaces 1 , t' 2 Input the thermal boundary conditions into the two finite element models respectively, because the thermal conductivity of the diamond anvil and the gasket 3 are known, and the temperature of the bottom surface of the diamond anvil is known, so only the temperature of the diamond anvil surface needs to be input. To obtain the overall temperature distribution of the diamond anvil, at this t...

Embodiment 3

[0036] Example 3 The example 1 of using the finite element software to realize the temperature measurement of the sample in the anvil by the diamond.

[0037] As the finite element software, well-known ANSYS software was used. According to the geometric dimensions of the upper and lower diamond anvils 1 and 2, the diameter of the bottom surface is 3 mm, the diameter of the anvil surface is 400 μm, and the height is 2.3 mm to construct two finite element models.

[0038] As in the device structure given in Example 1, the thermal conductivity of the upper and lower diamond anvils 1 and 2 is 1500 W / m·K. The gasket 3 is made of T301 steel sheet, the thermal conductivity corresponds to 17W / m·K, the diameter of the gasket 3 is 6mm, and the thickness is 0.25mm, and the sample 4 of potassium chloride material is placed in the sample cavity formed by pre-pressing and punching. The thermal conductivity of sample 4 is 10 W / m·K, the thickness of sample 4 is 50 μm, and the diameter of sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com