Preparation method and application of Ag/AgCl (silver/silver chloride) micro-electrode packaging film based on PDMS (polydimethylsiloxane)

A technology of encapsulating film and microelectrode, which is applied in the field of electrochemistry, can solve the problems of unresolved supporting electrolyte storage, easy falling off of the Ag/AgCl layer, short sustainable and stable working time, etc., and achieve stable work, low cost and high sensitivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of Ag / AgCl electrode:

[0022] The electrode substrate is prepared by mixing 90wt% PDMS and 10wt% silane coupling agent and curing at 100°C for 2 hours, and then hydrophilically modifying the electrode substrate. The modification solution consists of 5wt% (Gly) and 2wt% (PVA) Composition, soak the PDMS substrate in the modification solution for 20 minutes, take it out and dry it at 60°C for 2 hours and repeat the operation three times, and finally coat the silver nanowires evenly, dry at 60°C for 2 hours, then perform electrode oxidation treatment, soak in NaClO (20mg / mol) In the process, the Ag / AgCl electrode was obtained as the electrode working layer after being rinsed with deionized water and dried at 60 °C for 2 h.

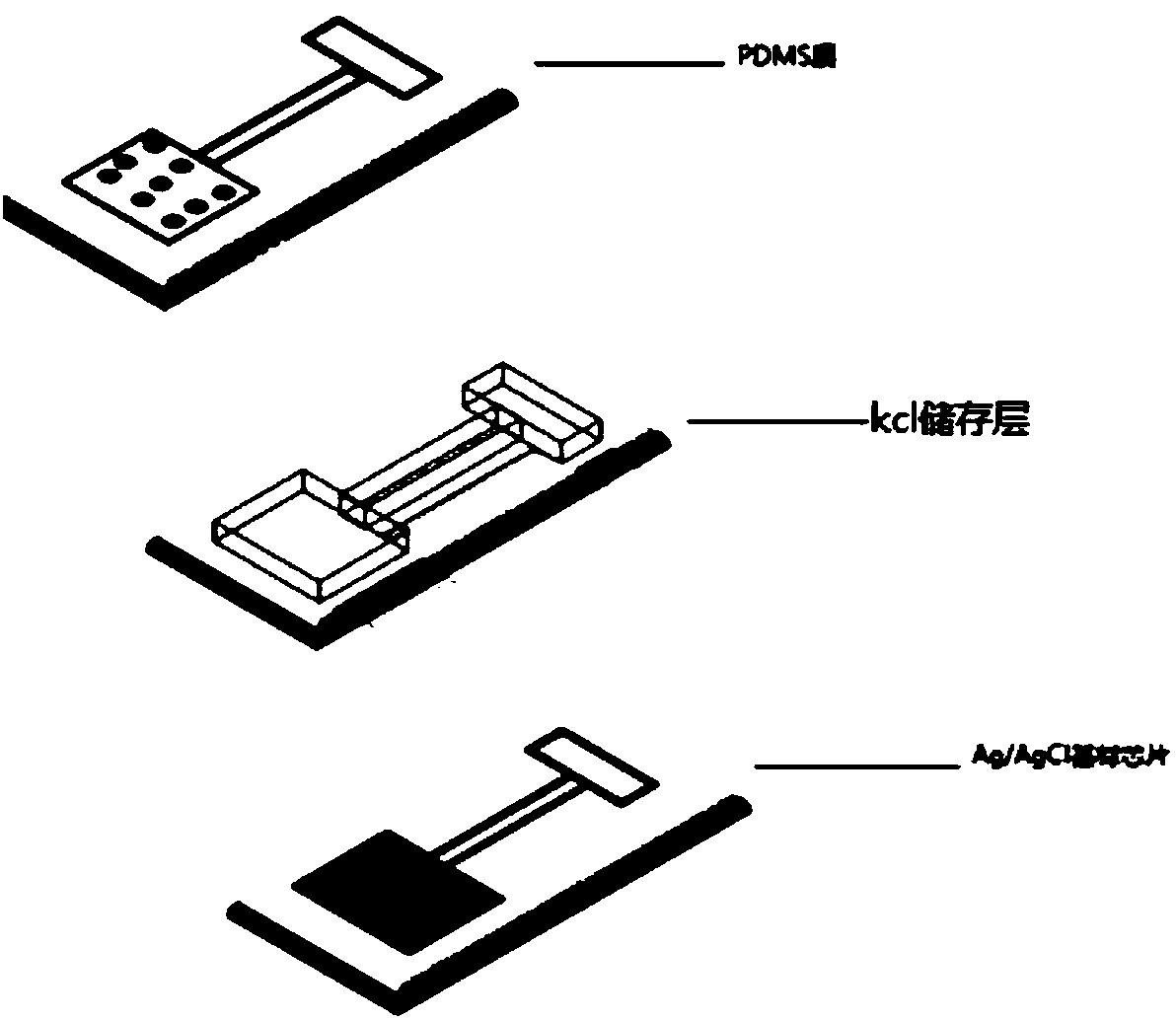

[0023] The middle layer adopts PDMS (prepared by mixing 90wt% PDMS and 10wt% silane coupling agent and curing at 100°C for 2h, and finally hollows out according to the shape of the electrode. The upper layer is a PDMS film (made of 80wt% PD...

Embodiment 2

[0025] The three-electrode system consists of a glassy carbon electrode as the working electrode, Ag / AgCl as the reference electrode, and platinum wire as the auxiliary electrode.

[0026] Pretreatment of glassy carbon electrodes: Grinding and activating glassy carbon electrodes, using Al with different particle sizes 2 0 3 The powder, from large to small, is placed on the buckskin and dripped with less than deionized water to polish the electrode.

[0027] Adopt the three-electrode system of this embodiment to carry out electrode test:

[0028] The three-electrode system is placed in the PBS (10×) buffer solution. Under the three-electrode system, the chronopotentiometry is used to set the cathodic current to 2 μA, the anode current to 2 μA, the cathodic time to 2 s, and the anodic time to 2 μA. is 600s, the initial polarity is anode, the data storage interval is 0.01s, the number of segments is 2, and the electrode polarity switching method is time.

[0029] For the selec...

Embodiment 3

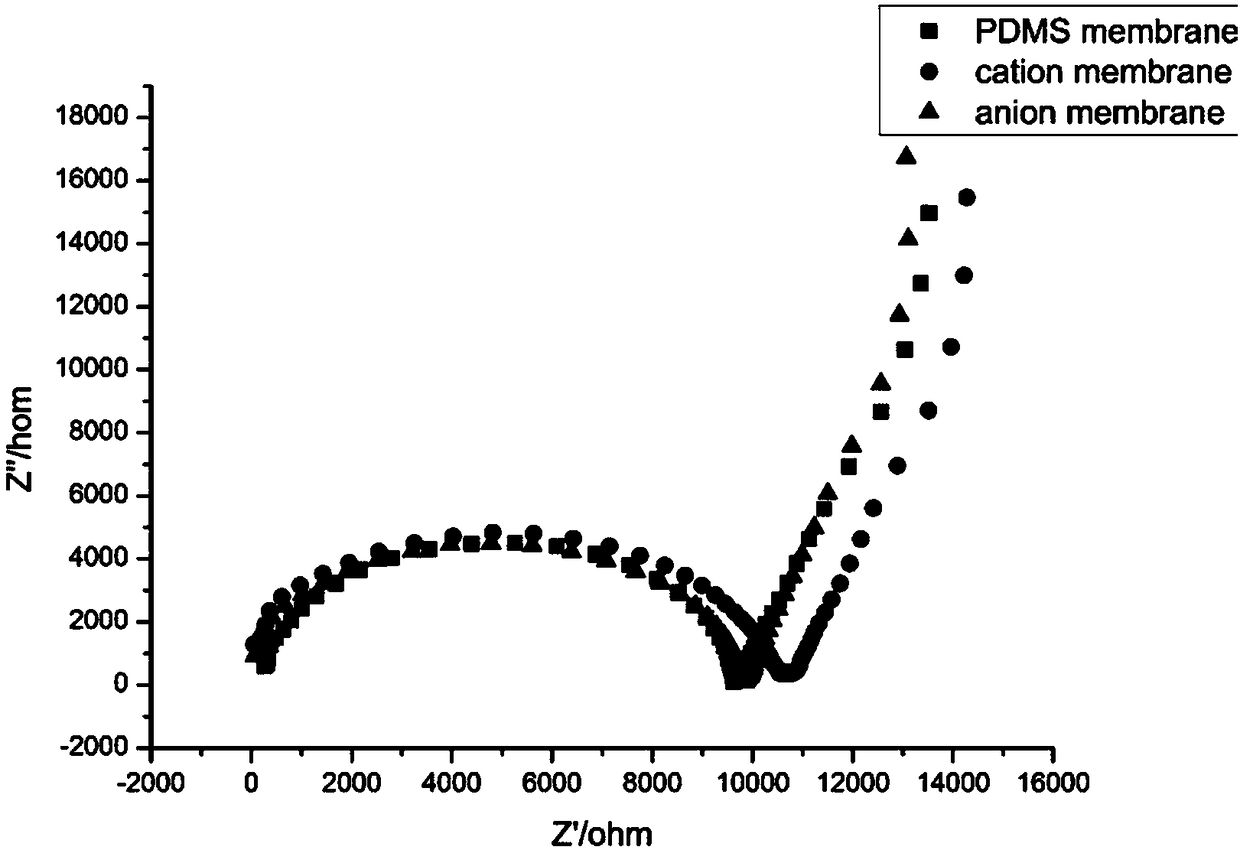

[0032] The anion and cation exchange membranes were used as the reference electrode encapsulation material to carry out the impedance test, and the influence of different encapsulation materials on the working performance of the electrode was compared.

[0033] The test system is a three-electrode system, which consists of a glassy carbon electrode as a working electrode, an Ag / AgCl microelectrode as a reference electrode, and a platinum wire as an auxiliary electrode.

[0034] The three-electrode system was placed in KCl (10 -4 mol / L) solution, under the three-electrode system, adopt the impedance method, set the test time as 600s, the upper limit frequency as 10Hz, and the lower limit frequency as 100000Hz. The test results are attached image 3 .

[0035] like image 3 It is shown that the PDMS encapsulation membrane prepared by the present invention has the smallest impedance radius and the smallest resistance value in the low frequency region, compared with the anion e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com