Aluminum-lithium alloy composite negative electrode sheet for solid-state battery and preparation method and application thereof

An aluminum-lithium alloy and solid-state battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high-temperature resistance of metal Li, difficulty in battery assembly and application, and reduction of lithium content, and achieve high power density and structure Tight, long shelf life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

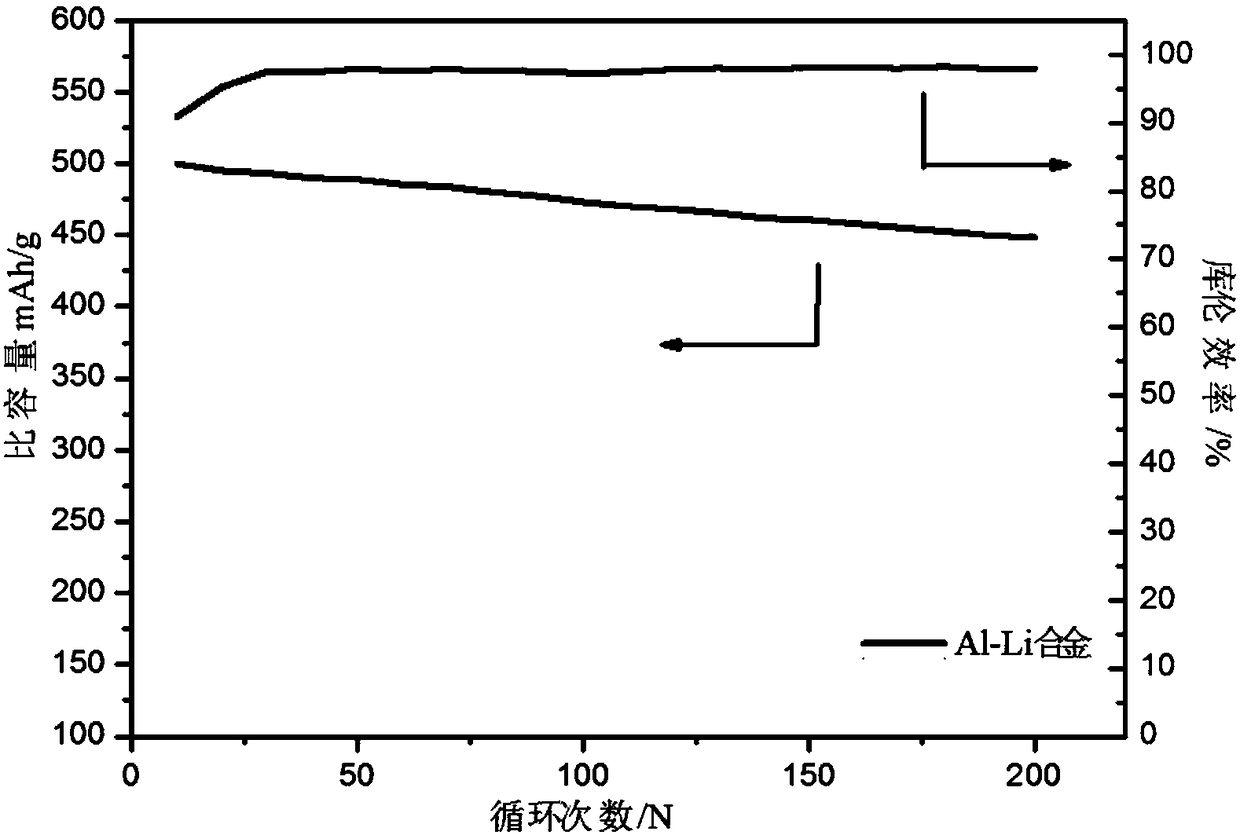

[0021] The invention discloses an aluminum-lithium alloy composite negative electrode sheet for a solid-state battery. The aluminum-lithium alloy composite negative electrode is composed of aluminum-lithium alloy powder, propylene carbonate, Surpe-P, polyvinylidene fluoride, polyethylene oxide and LiTFSI.

[0022] A method for preparing an aluminum-lithium alloy composite negative electrode sheet for a solid-state battery, step 1: in an inert atmosphere, soak aluminum-lithium alloy powder in a propylene carbonate solution for 0.5 hours according to a mass ratio of 1:10, and then soak the The mixed material of aluminum-lithium alloy powder and propylene carbonate is taken out;

[0023] Step 2: Blending the mixed material of 75 parts by mass of aluminum-lithium alloy powder and propylene carbonate and 3 parts by mass of Surpe-P in a vacuum mixer;

[0024] Step 3: uniformly disperse the blended mixed powder and 4 parts by mass of polyvinylidene fluoride in the NMP solution, and t...

Embodiment 2

[0030] The invention discloses an aluminum-lithium alloy composite negative electrode sheet for solid-state batteries. The aluminum-lithium alloy composite negative electrode is composed of aluminum-lithium alloy powder, fluoroalkyl phosphate, acetylene black, polytetrafluoroethylene, polyethylene oxide and LiClO4.

[0031] A method for preparing an aluminum-lithium alloy composite negative electrode sheet for a solid-state battery, step 1: in an inert atmosphere, soak aluminum-lithium alloy powder in a propylene carbonate solution for 1 hour according to a mass ratio of 1:10, and then soak the The mixed material of aluminum-lithium alloy powder and fluoroalkyl phosphate is taken out;

[0032] Step 2: Blending the mixed material of 78 parts by mass of aluminum-lithium alloy powder and fluoroalkyl phosphate and 3 parts by mass of acetylene black in a vacuum mixer;

[0033] Step 3: uniformly disperse the blended mixed powder and 4 parts by mass of polytetrafluoroethylene in the ...

Embodiment 3

[0039] The present invention is an aluminum-lithium alloy composite negative electrode sheet for a solid-state battery. The aluminum-lithium alloy composite negative electrode is composed of aluminum-lithium alloy powder, cresol diphenyl phosphate, KS-6, carboxymethyl cellulose, polyethylene oxide and LiBF4 .

[0040] A preparation method of an aluminum-lithium alloy composite negative electrode sheet for a solid-state battery, step 1: in an inert atmosphere, according to a mass ratio of 1:10, the aluminum-lithium alloy powder is soaked in a propylene carbonate solution for 1.5 hours, and then the soaked The mixed material of aluminum-lithium alloy powder and cresol diphenyl phosphate is taken out;

[0041] Step 2: Blending the mixed material of 81 parts by mass of aluminum-lithium alloy powder and cresol diphenyl phosphate and KS-6 of 2 parts by mass in a vacuum mixer;

[0042] Step 3: uniformly disperse the blended mixed powder and 3 parts by mass of carboxymethyl cellulose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com