Hydroxypropyl methyl cellulose hollow capsule with high oxygen isolation rate and preparing method of hydroxypropyl methyl cellulose hollow capsule

A technology of hollow capsules and hydroxypropylmethyl, which is applied in capsule delivery, pharmaceutical formula, powder delivery, etc. It can solve the problems of broken capsule fragments, reduce friability, improve oxygen barrier and toughness, and reduce oxygen oxidation. risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~20

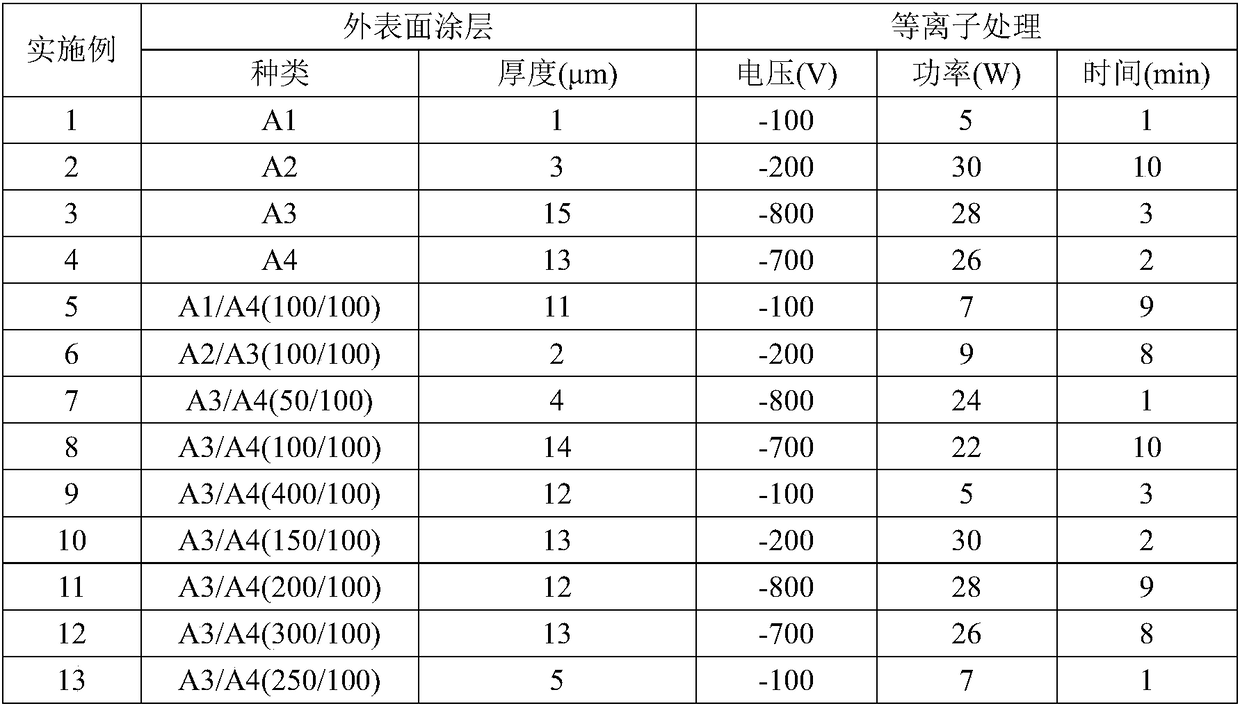

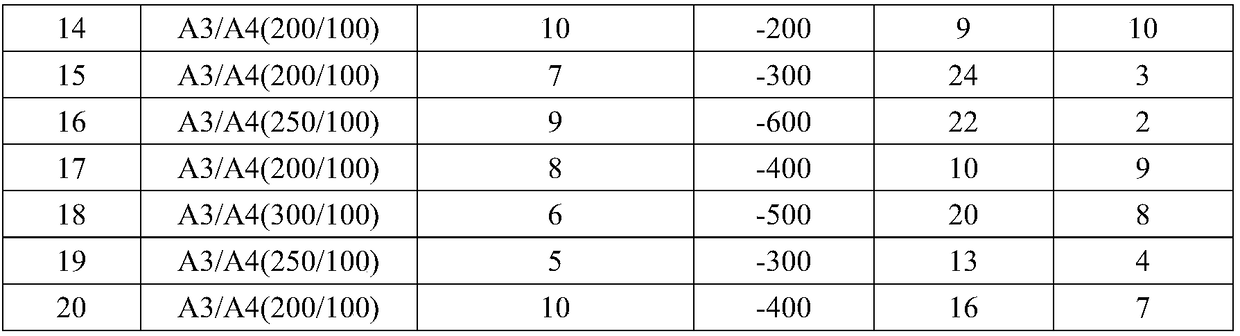

[0042] According to the raw materials and proportions of the outer surface coating shown in Table 1, and the conditions of plasma treatment, the hypromellose hollow capsules of the present invention are prepared according to the following steps.

[0043] Step 1. Dissolve hydroxypropyl methylcellulose (produced in Lotte Korea, AN6) in water to make an aqueous solution, immerse the 3# hollow capsule mold in the hydroxypropyl methylcellulose solution and dip it in glue, take it out and dry it on the surface of the capsule mold Form a layer of hypromellose film;

[0044] Step 2. Uniformly disperse the raw materials of the outer surface coating in ethanol according to the proportion shown in Table 1 to obtain the outer surface coating mixed solution. Dip the mold containing the cellulose film in step 1 into the outer surface coating mixture, dry to remove ethanol and cool to room temperature.

[0045] Step 3, applying bias plasma treatment according to the conditions shown in Table ...

Embodiment 21

[0051] Hypromellose hollow capsules with the same thickness were prepared by using the raw materials and proportions of the hydroxypropylmethylcellulose and the outer surface coating in Example 20, but without the plasma treatment in step 3 in the example.

Embodiment 22

[0053] Hypromellose hollow capsules with the same thickness were prepared by using the raw materials and proportions of the hydroxypropylmethylcellulose and the outer surface coating in Example 4, but the plasma treatment was carried out in a nitrogen atmosphere.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com