Polyamide composite reverse osmosis membrane with high flux and high rejection rate and preparation method thereof

A technology of reverse osmosis membrane and polyamide, which is applied in the field of membrane separation and can solve the problems of the influence of salt rejection rate and the reduction of desalination rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

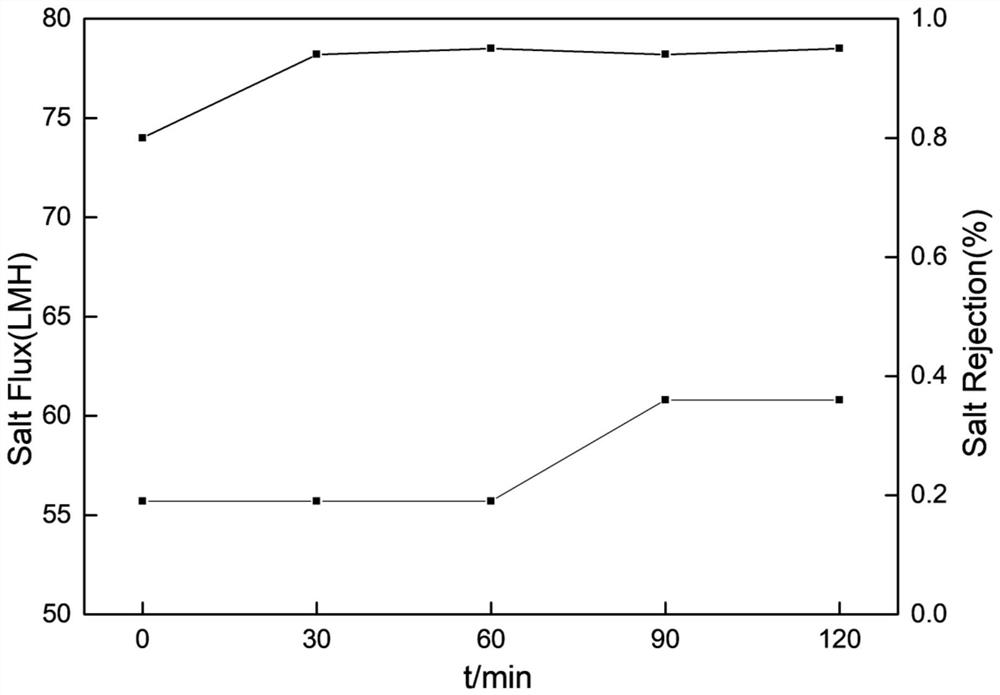

Image

Examples

Embodiment 1

[0038] This embodiment discloses a method for preparing a polyamide composite reverse osmosis membrane with high flux and high rejection rate, comprising the following steps:

[0039] 1) Preparation of nanofiber membrane: take the PVA-co-PE nanofiber suspension and coat it on the surface of PP, and the quality of the prepared nanofiber membrane is 30g / m 2 .

[0040] 2) Preparation of aqueous phase solution: 0.05% by mass of sodium dodecylsulfonate, 0.1% by mass of camphorsulfonic acid, 0.1% by mass of triethylamine and 0.1% by mass of m-phenylenediamine monomer, were dissolved into In deionized water, a mixed solution is obtained, and 2% urea by mass percentage is also added in the mixed solution as a cosolvent to prepare an aqueous phase solution;

[0041] 3) Prepare an oil phase solution: Dissolve trimesoyl chloride monomer in n-hexane to prepare an oil phase solution with a mass percentage of 0.01%;

[0042] 4) Preparation of polyamide composite reverse osmosis membrane: ...

Embodiment 2

[0044] 1) Preparation of nanofiber membrane: take the PVA-co-PE nanofiber suspension and coat it on the surface of PP, and the quality of the prepared nanofiber membrane is 50g / m 2 .

[0045] 2) Prepare the aqueous phase solution: take sodium dodecylsulfonate as 1% by mass, 5% by mass of camphorsulfonic acid, 4% by mass of triethylamine and 5% by mass of m-phenylenediamine monomer, dissolve to In deionized water, a mixed solution was obtained, and 5% p-aminobenzoic acid was added in the mixed solution as a cosolvent by mass percentage to prepare an aqueous phase solution;

[0046] 3) Prepare an oil phase solution: Dissolve trimesoyl chloride monomer in n-hexane to prepare an oil phase solution with a mass percentage of 5%;

[0047]4) Preparation of polyamide composite reverse osmosis membrane: take the nanofiber membrane prepared in step 1) and immerse it in the aqueous phase solution of step 2) to react for about 10 minutes, remove excess aqueous phase solution, and then add...

Embodiment 3

[0049] 1) Preparation of nanofiber membrane: take the PVA-co-PE nanofiber suspension and coat it on the surface of PP, and the quality of the prepared nanofiber membrane is 80g / m 2 .

[0050] 2) Preparation of aqueous phase solution: take sodium dodecylsulfonate mass percentage as 0.2%, camphorsulfonic acid mass percentage 2%, triethylamine mass percentage 1% and m-phenylenediamine monomer mass percentage as 2% and dissolve into In deionized water, a mixed solution was obtained, and 8% salicylic acid was added in the mixed solution as a cosolvent by mass percentage to prepare an aqueous phase solution;

[0051] 3) Prepare an oil phase solution: Dissolve trimesoyl chloride monomer in n-hexane to prepare an oil phase solution with a mass percentage of 3%;

[0052] 4) Preparation of polyamide composite reverse osmosis membrane: take the nanofiber membrane prepared in step 1) and immerse it in the aqueous phase solution of step 2) to react for about 10 minutes, remove excess aque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com