Laser welding method for steel/aluminum dissimilar material

A technology of laser welding and dissimilar materials, which is applied in laser welding equipment, welding/cutting media/materials, welding media, etc., can solve problems such as cracking, limited strength improvement of welded joints, and difficulty in reaching them, so as to improve metallurgical reactions and reduce protection Gas costs and welding environmental requirements, the effect of reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

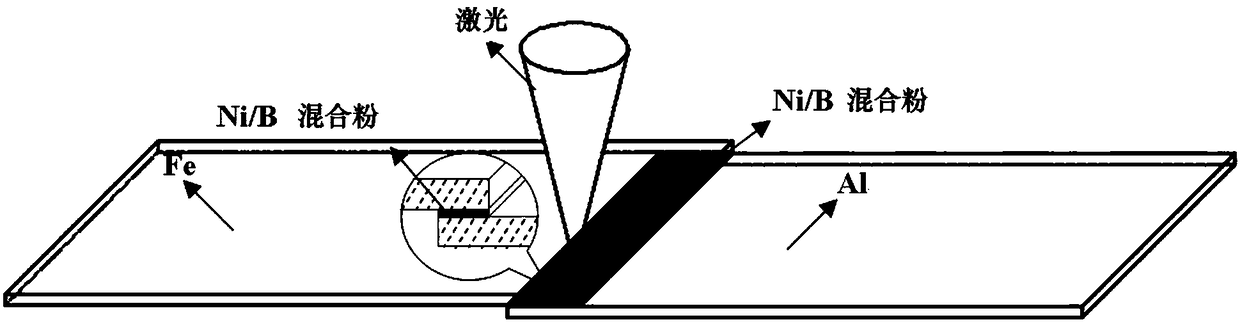

[0027] A laser welding method for steel / aluminum dissimilar materials, comprising the steps of:

[0028] Step (1): Select 1.5mm thick DP590 and AA6061 aluminum alloys, and use acetone to degrease;

[0029] Step (2): Pre-preparing Ni / B mixed powder with a thickness of 0.06mm on the surface of the cleaned AA6061 aluminum alloy, with a particle size of 20nm to 200μm;

[0030] Step (3): Place the treated steel plate and aluminum alloy on the workbench in the form of a steel upper aluminum lower overlap, and use a special welding fixture to make the two steel plates closely contact.

[0031] Step (4): Use the IPG-6kW fiber laser to perform lap welding on the test plate, and the shielding gas is 95% Ar+5% CO 2 / O 2 mixed composition.

[0032] After welding, the macroscopic appearance of the weld was observed to be excellent, without obvious spatter, Ni-Al intermetallic compound was precipitated at the interface, the thickness of the Fe-Al intermetallic compound layer was about 20...

Embodiment 2

[0034] Step (1): Select 1.5mm thick DP590 and AA6061 aluminum alloys, and use acetone to degrease;

[0035] Step (2): Pre-preparing Ni / B mixed powder with a thickness of 0.1 mm on the surface of the cleaned AA6061 aluminum alloy, with a particle size of 20 nm to 200 μm;

[0036] Step (3): Place the treated steel plate and aluminum alloy on the workbench in the form of a steel upper aluminum lower overlap, and use a special welding fixture to make the two steel plates closely contact.

[0037] Step (4): Use the IPG-6kW fiber laser to perform lap welding on the test plate, and the shielding gas is 85% Ar+15% CO 2 / O 2 mixed composition.

[0038] After welding, the macroscopic appearance of the weld seam is excellent, there is no obvious spatter, the precipitation of Ni-Al intermetallic compound at the interface increases significantly, the thickness of the Fe-Al intermetallic compound layer is about 10 μm, and the strength of the welded joint reaches 120MPa

[0039]The main p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com