Migration-free low-Mooney rebound reclaimed rubber and preparation method thereof

A technology of reclaimed rubber and low Mooney, applied in the field of reclaimed rubber, can solve the problems of large pollution, Mooney rebound, oil loss on the surface of rubber materials, etc., and achieve the effect of improving compatibility, excellent performance and inhibiting precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

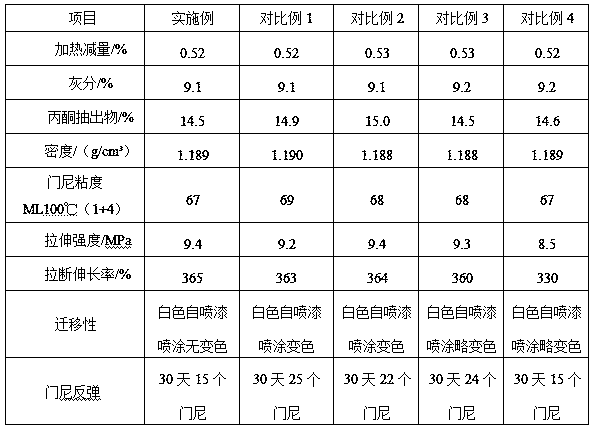

[0041] A reclaimed rubber with no migration and low Mooney rebound, comprising the following components in parts by mass:

[0042] 40 mesh truck tire full tire rubber powder 100 parts

[0043] Bulking agent castor oil 10 parts

[0044] Regeneration activator B910 0.25 parts

[0045] Tackifier wood rosin 2.5 parts

[0046] Reinforcing resin RE resin 1.5 parts

[0047] Deodorant montmorillonite nano-reaction additive 3 parts

[0048] Adsorbent white carbon black 1.5 parts

[0049] Mooney control agent CTP 0.5 parts

[0050] Friedel-Craftene 1 part.

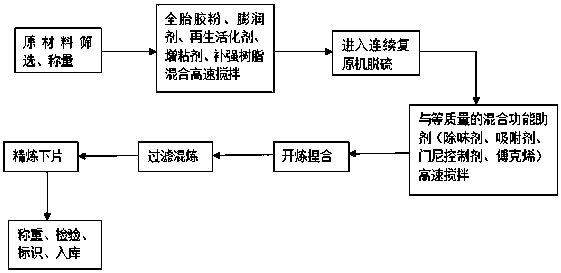

[0051] A method for preparing reclaimed rubber with no migration and low Mooney rebound, specifically comprising the following technical process:

[0052] (1) Screening and weighing of raw materials.

[0053] (2) Whole tire rubber powder for truck tires, swelling agent castor oil, regeneration activator B910, tackifier wood rosin, reinforcing resin RE resin in a mixing tank at a temperature of 120°C for 225 seconds at high s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com