Concrete waterproof agent

A technology of concrete waterproofing agent and sodium methyl silicate, which is applied in the field of concrete waterproofing agent, can solve the problems of poor adhesion between waterproofing agent and foundation surface, time-consuming and laborious surface treatment, long maintenance time, etc., and achieve good waterproof effect and enhanced Good original strength and self-healing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

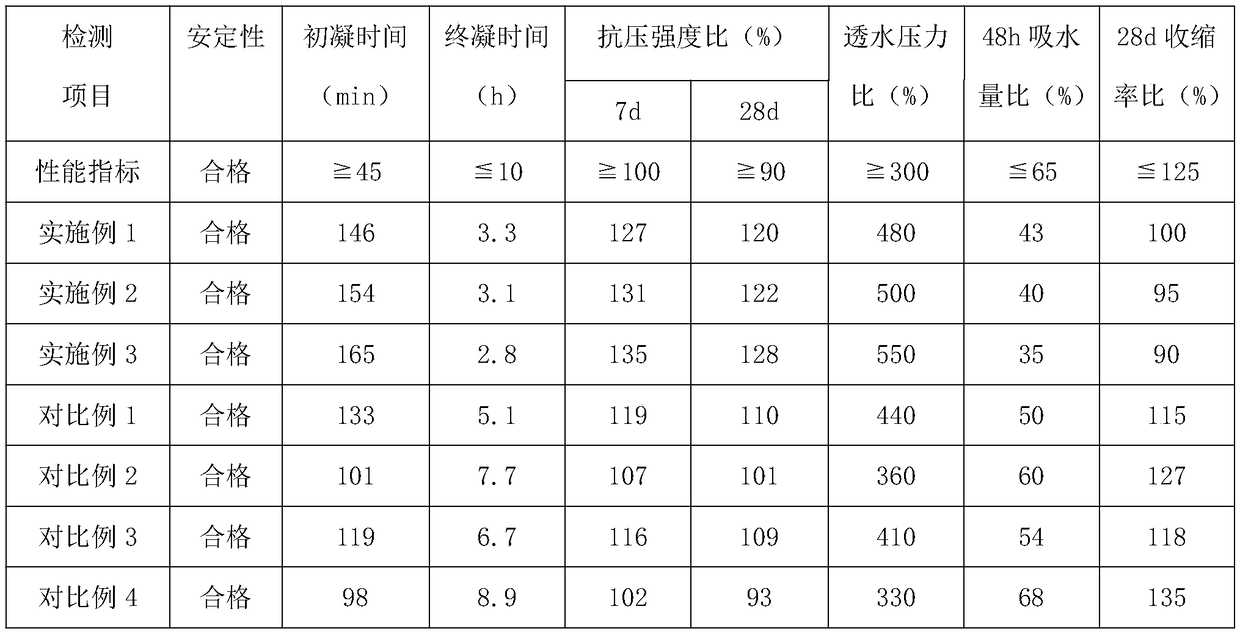

Examples

Embodiment 1

[0037] A concrete waterproofing agent, comprising the following components in mass percentage: 50% sodium methyl silicate-calcium hydroxide composite solution, 30% sodium silicate solution, 3% sodium citrate, 2% triethanolamine, hydroxyl Propyl methyl cellulose 2%, tackifier 80A5 10.6%, pectin 3%, JX anti-crack silicon water repellent 5%, aluminum sulfide 1%, tert-butyldiphenylchlorosilane 0.4%, rosin base Hyperbranched epoxy resin 3%. Wherein the viscosity of hydroxypropyl methylcellulose is 120000-180000mPa·s, the solid content of the sodium silicate solution is 40%, and the modulus of the sodium silicate solution is 2.2-3.2.

[0038] The preparation method of the sodium methyl silicate-calcium hydroxide composite solution is as follows: Weigh 80% of the sodium methyl silicate solution with a solid content of 10% and 20% of the calcium hydroxide, stir in the reaction kettle until there is no agglomeration, Let it stand for 1 day, and take the supernatant liquid.

[0039] P...

Embodiment 2

[0041] A concrete waterproofing agent, comprising the following components in mass percentage: 60% sodium methyl silicate-calcium hydroxide composite solution, 20% sodium silicate solution, 1% sodium citrate, 3% triethanolamine, hydroxyl Propyl methyl cellulose 5%, tackifier 80A5 10.3%, pectin 2.5%, JX anti-crack silicon water repellent 5%, aluminum sulfide 2%, tert-butyldiphenylchlorosilane 0.2%, rosin base Hyperbranched epoxy resin 1%. Wherein the viscosity of hydroxypropyl methylcellulose is 160000mPa·s, the solid content of the sodium silicate solution is 50%, and the modulus of the sodium silicate solution is 2.2-3.2.

[0042] The preparation method of sodium methyl silicate-calcium hydroxide composite solution is as follows: Weigh 90% of sodium methyl silicate solution and 10% of calcium hydroxide with a solid content of 10%, stir in the reaction kettle until there is no agglomeration, Let it stand for 1 day, and take the supernatant liquid.

[0043] Preparation method...

Embodiment 3

[0045] A concrete waterproofing agent, comprising the following components in mass percentage: 55% sodium methyl silicate-calcium hydroxide composite solution, 25% sodium silicate solution, 3% sodium citrate, 3% triethanolamine, hydroxyl Propyl methyl cellulose 3%, tackifier 80A5 10.5%, pectin 2%, JX anti-crack silicon water repellent 5%, aluminum sulfide 1%, tert-butyldiphenylchlorosilane 0.5%, rosin base Hyperbranched epoxy resin 2%. Wherein the viscosity of hydroxypropyl methylcellulose is 180000mPa·s, the solid content of the sodium silicate solution is 45%, and the modulus of the sodium silicate solution is 2.2-3.2.

[0046] The preparation method of sodium methyl silicate-calcium hydroxide composite solution is as follows: Weigh 85% of sodium methyl silicate solution and 15% of calcium hydroxide with a solid content of 10%, stir in the reaction kettle until there is no agglomeration, Let it stand for 1 day, and take the supernatant liquid.

[0047] Preparation method: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com