Method for continuously preparing 2-methylallyl alcohol

A technology of methallyl alcohol and methallyl chloride, which is applied in the field of continuous preparation of 2-methallyl alcohol, can solve problems such as troublesome operation, achieve less by-products, high reaction selectivity, and high yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

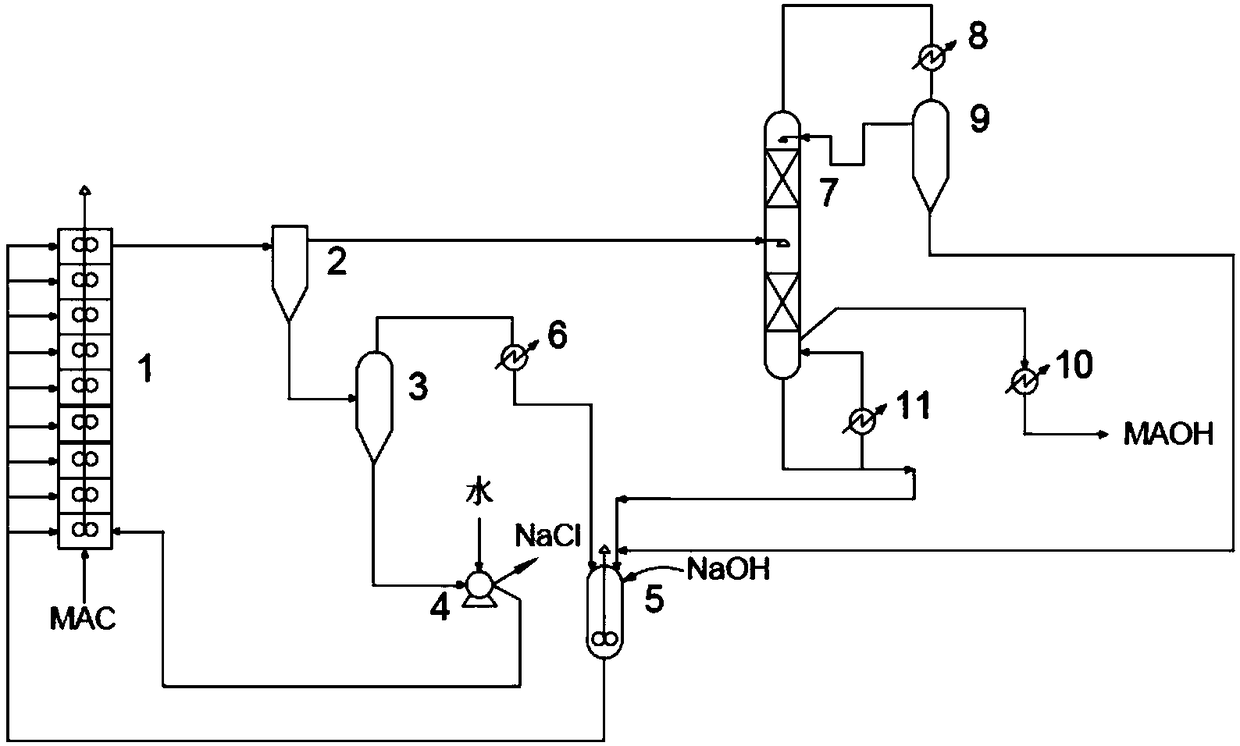

[0046] exist figure 1 Shown total volume is 6 stages of stirring series reactor 1 bottoms of 500L with 136Kg / hour to pass through the sodium acetate solution (containing sodium acetate 36.0%, sodium chloride 7.5%, about 75 ℃ of temperature) that reaches balance through continuous mechanical application, simultaneously Pass into MAC with 9.05Kg / hour; Pass into the sodium hydroxide solution (containing sodium hydroxide 41%) that total amount is 9.8Kg / hour respectively in 6 stirring sections, the feeding amount of every section is controlled with pH meter (pH value is controlled at 11), at this moment, residence time is about 4 hours. At the outlet of the upper part of the reactor 1, the temperature of the reaction product is about 100° C., and the layer passes through the continuous stratifier 2. The oil layer enters the middle part of the continuous azeotropic distillation column 7, and the water layer enters the flasher 3.

[0047] Under the condition that the heat source ...

Embodiment 2

[0050] exist figure 1 Shown total volume is 10 stages of stirring series reactor 1 bottoms of 500L with 315Kg / hour to pass through the sodium acetate solution (containing sodium acetate 38.5%, sodium chloride 7.3%, about 89 ℃ of temperature) that reaches equilibrium through continuous mechanical application, simultaneously Feed MAC with 18.1Kg / hour; Feed the sodium hydroxide solution (containing sodium hydroxide 40%) that total amount is 20.0Kg / hour in 10 stirring sections respectively, the feeding amount of every section is controlled with pH meter (pH value is controlled at 10), at this moment, residence time is about 2 hours. At the outlet of the reactor 1, the temperature of the reaction product is about 110° C., and the layer passes through the continuous stratifier 2. The oil layer enters the middle part of the continuous azeotropic distillation column 7, and the water layer enters the flasher 3.

[0051] Under the condition that the heat source is provided by the re...

Embodiment 3

[0054] exist figure 1 Shown total volume is 500L 15 stages of stirred series reactor 1 bottoms with 597Kg / hour pass through the sodium acetate solution (containing sodium acetate 41.2%, sodium chloride 7.0%, about 101 ℃ of temperature) that reaches balance through continuous mechanical application, simultaneously Pass into MAC with 27.15Kg / hour; Feed in the sodium hydroxide solution (containing sodium hydroxide 39%) that total amount is 30.9Kg / hour in 15 stirring sections respectively, the feeding amount of every section is controlled with pH meter (pH value is controlled at 9), at this time, the residence time is about 1 hour. At the outlet of the reactor, the temperature of the reaction product is about 120° C., and the layer passes through the continuous stratifier 2 , the oil layer enters the middle part of the continuous azeotropic distillation column 7 , and the water layer enters the flasher 3 .

[0055] Under the condition that the heat source is provided by the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com