High-filling high toughness epoxy stone adhesive and preparation method thereof

A high-toughness, adhesive technology, applied in the direction of adhesives, epoxy resin glue, non-polymer adhesive additives, etc., can solve the problems of high cost and inability to meet the application of building materials, so as to reduce viscosity, improve wettability, avoid The effect of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the above-mentioned high-filling high-toughness epoxy stone adhesive comprises the following steps:

[0038] 1) Weigh 30 to 50 parts of epoxy resin, 1 to 5 parts of difunctional reactive diluent and 100 to 150 parts of composite filler in parts by weight;

[0039] 2) Stir the epoxy resin and the bifunctional active diluent evenly, then add the composite filler, stir evenly, and cool to obtain component A;

[0040] 3) Weighing 15-40 parts of self-catalyzed toughness curing agent composition and 50-200 parts of composite filler according to the ratio of parts by weight;

[0041] 4) Stir the self-catalyzed toughening agent composition evenly, then add it into the composite filler, stir evenly, and cool to obtain component B;

[0042] 5) Mix the two components A and B according to the above weight ratio to obtain a high-filling and high-toughness epoxy stone adhesive.

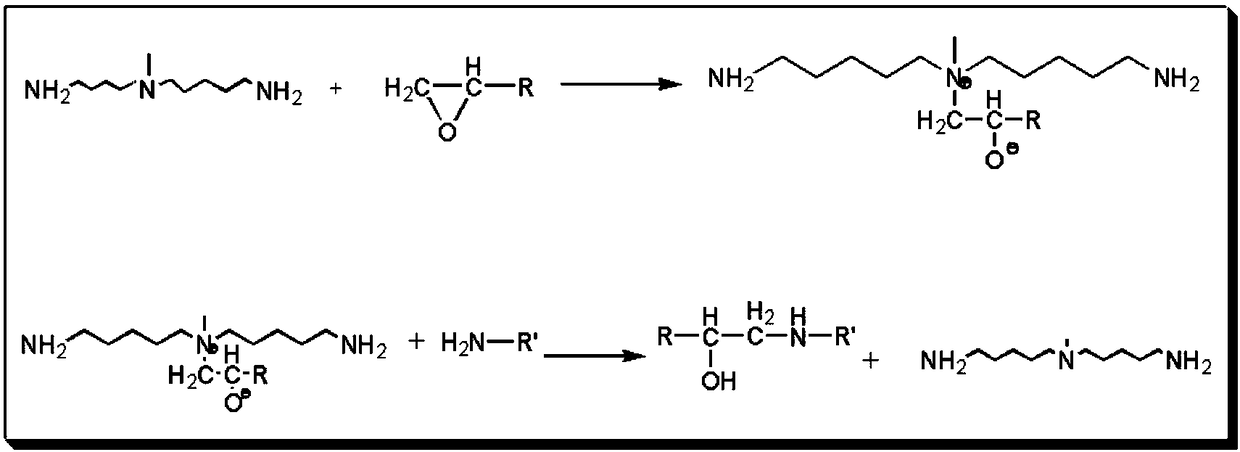

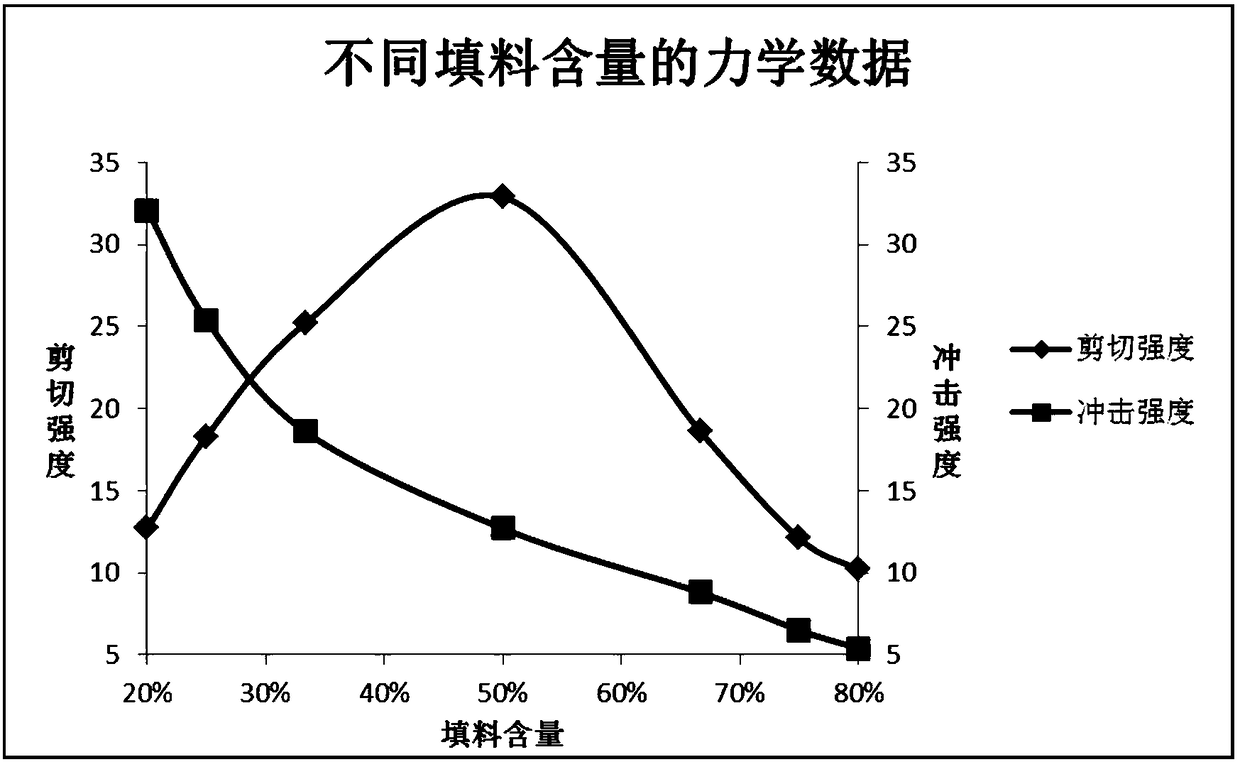

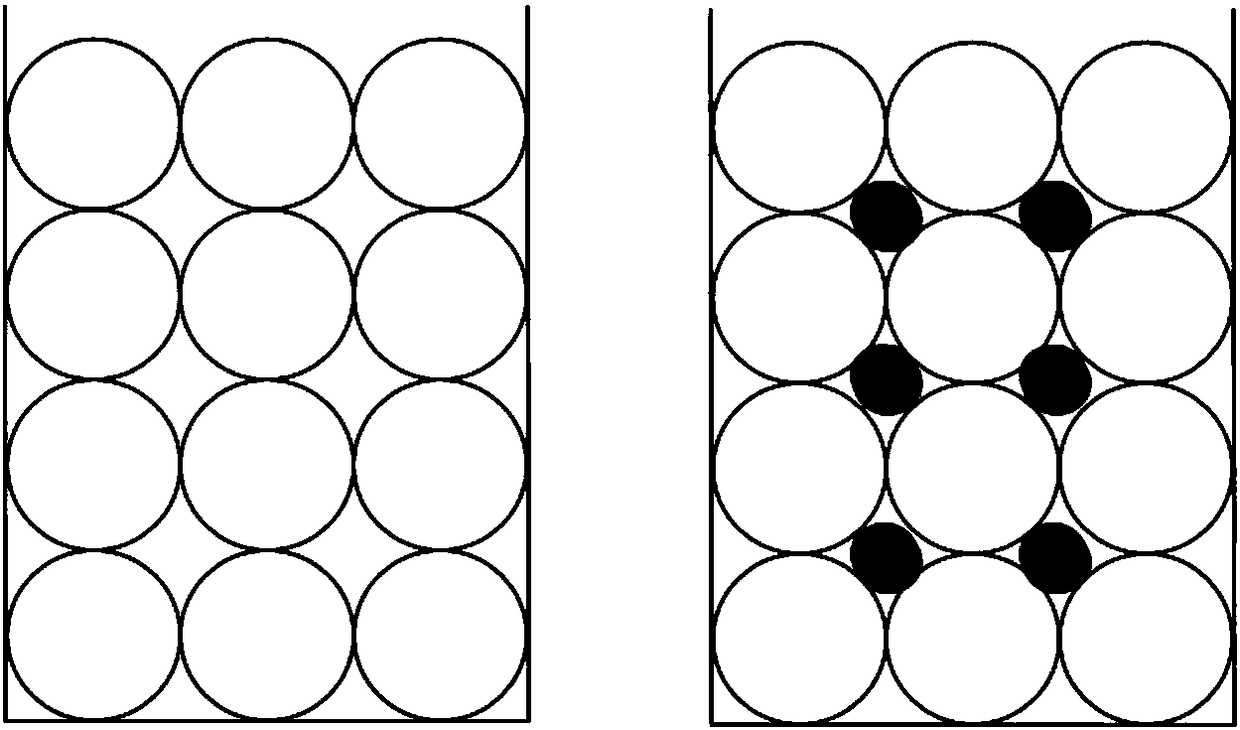

[0043] Theoretical basis of above-mentioned raw material and preparation meth...

Embodiment 1

[0072] Preparation of group A: Stir 30 parts of bisphenol A epoxy resin E44 and 1 part of polyethylene glycol diglycidyl ether evenly, and then add 100 parts of composite filler. First add 50 parts of lignin and stir for 20 minutes. After the lignin is evenly dispersed, add 50 parts of 400-mesh quartz powder, stir for another 10 minutes, cool to room temperature and discharge.

[0073] Preparation of Group B: Mix 3 parts of N-(6-aminohexyl)-N-methyl-1,6-hexanediamine and 12 parts of polyetheramine D230, and then add 50 parts of composite filler. First add 25 parts of lignin and stir for 20 minutes. After the lignin is evenly dispersed, add 25 parts of 400-mesh quartz powder and stir for another 10 minutes. Cool to room temperature and discharge.

[0074] Mix A and B components at a weight ratio of 1:1 to obtain highly filled and high toughness epoxy stone adhesive 1.

Embodiment 2

[0076] Preparation of group A: Stir 50 parts of bisphenol A epoxy resin E51 and 5 parts of diethylene glycol diglycidyl ether evenly, and then add 150 parts of composite filler. First add 7.5 parts of hydroxymethyl cellulose, stir for 20 minutes, after the hydroxymethyl cellulose is uniformly dispersed, then add 142.5 parts of 300 mesh quartz powder, stir for another 10 minutes, cool to room temperature and discharge.

[0077] Preparation of Group B: Stir evenly with 32 parts of N-(6-aminohexyl)-N-methyl-1,6-hexanediamine and 8 parts of polyetheramine T403 (functionality 3, molecular weight 400), and then add 200 Composite filler. First add 10 parts of hydroxymethylcellulose and stir for 20 minutes. After the hydroxymethylcellulose is evenly dispersed, add 190 parts of 300-mesh quartz powder, stir for 10 minutes, cool to room temperature and discharge.

[0078] Mix the two components A and B at a weight ratio of 1:1 to obtain a high-filling and high-toughness epoxy stone adhe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amine value | aaaaa | aaaaa |

| Amine value | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com