Self-repairing, low-damage and ultra-high temperature-resistant fracturing fluid

An ultra-high temperature, fracturing fluid technology, applied in the direction of production fluid, wellbore/well components, drilling composition, etc., can solve the problems affecting performance, fracturing fluid is easy to decompose, etc., to achieve convenient operation, low cost, The effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment adopts five kinds of monomers of acrylamide, acrylic acid, 2-acrylamido-2-methylpropanesulfonic acid, N-vinylpyrrolidone and dimethyl octadecyl allyl ammonium chloride in a weight ratio of 60:20:18:1.5:0.1 Initiate polymerization at 30°C, obtain a copolymer after polymerization for 10 hours, then shred the copolymer, dry it at 40°C, and finally pulverize it to pass through a 250-mesh sieve to obtain a polymer Thickener powder. The polymer thickener is formulated into a 0.4wt% solution, and 0.015wt% polyethyleneimine and 0.04wt% ammonium persulfate are added, and the fracturing fluid is obtained after thorough stirring.

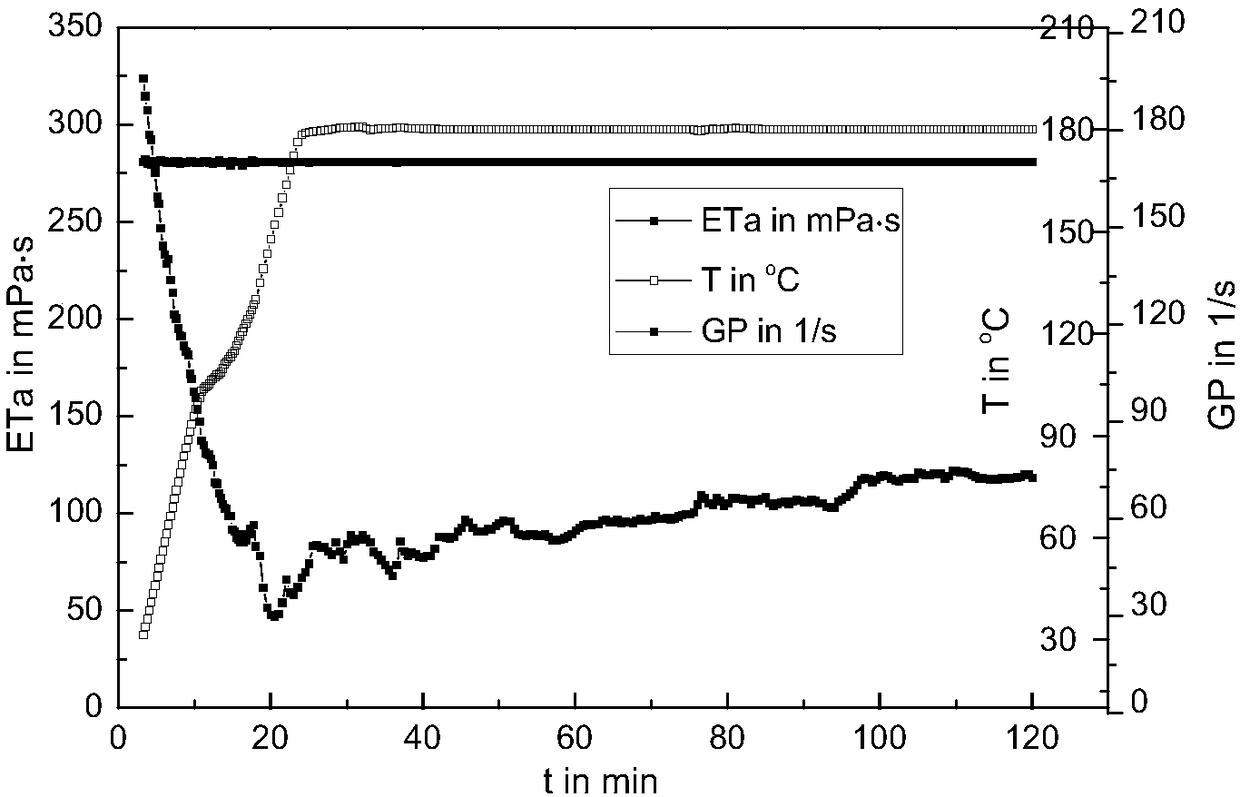

[0028] in the 170s -1 , The curve of the apparent viscosity of the high temperature resistant fracturing fluid system with time at 180°C, as shown in figure 1 shown. From figure 1 It can be seen that when the temperature rises, the apparent viscosity of the high-temperature resistant fracturing fluid drops sharply. When it reaches 18...

Embodiment 2

[0030] In this embodiment, five monomers of acrylamide, acrylic acid, 2-acrylamido-2-methylpropanesulfonic acid, N-vinylpyrrolidone and methyldiallyl ammonium chloride are used in a weight ratio of 65:20: 15:2.0:0.5 Initiate polymerization at 35°C, obtain a copolymer after polymerization for 10 hours, then shred the copolymer, dry it at 40°C, and finally pulverize it to pass through a 250-mesh sieve to obtain a polymer thickener powder . Next, the polymer was formulated into a 0.4wt solution, and 0.015wt% of polyethyleneimine and 0.04wt% of ammonium persulfate were added and fully stirred to obtain a fracturing fluid.

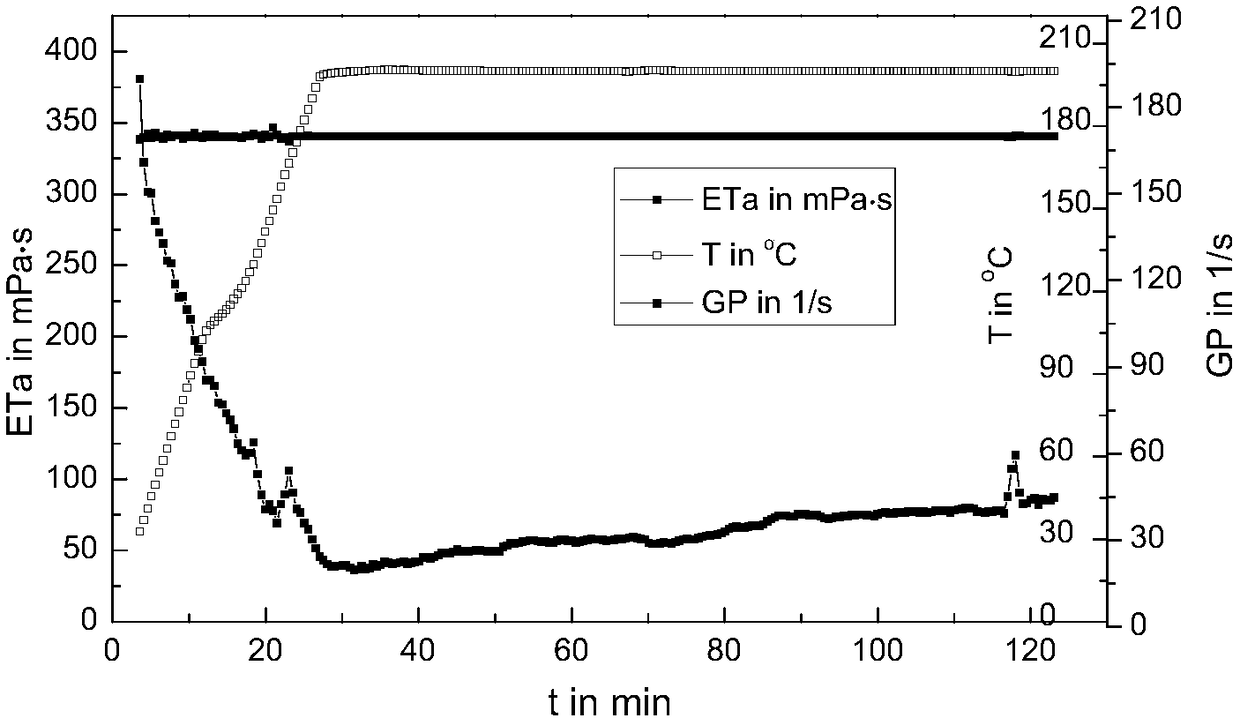

[0031] in the 170s -1 , The curve of the apparent viscosity of the high temperature resistant fracturing fluid system with time at 200°C, as shown in figure 2 shown. From figure 2 It can be seen that when the temperature rises, the apparent viscosity of the high-temperature resistant fracturing fluid drops sharply. When it reaches 200°C, the viscosity is ...

Embodiment 3

[0033] In this embodiment, five monomers of acrylamide, acrylic acid, 2-acrylamido-2-methylpropanesulfonic acid, sodium p-styrenesulfonate and methacryloxyethyltrimethylammonium chloride are used in weight ratio Initiate polymerization at 30°C at 65:17:15:2.0:1.0, obtain a copolymer after 10 hours of polymerization, then shred the copolymer, dry it at 40°C, and finally pulverize it to pass through a 200-mesh sieve to obtain a polymerization thickener powder. Next, the polymer is formulated into a 0.6wt% solution, and 0.02wt% polyethyleneimine and 0.06wt% ammonium persulfate capsules are added and fully stirred to obtain a fracturing fluid.

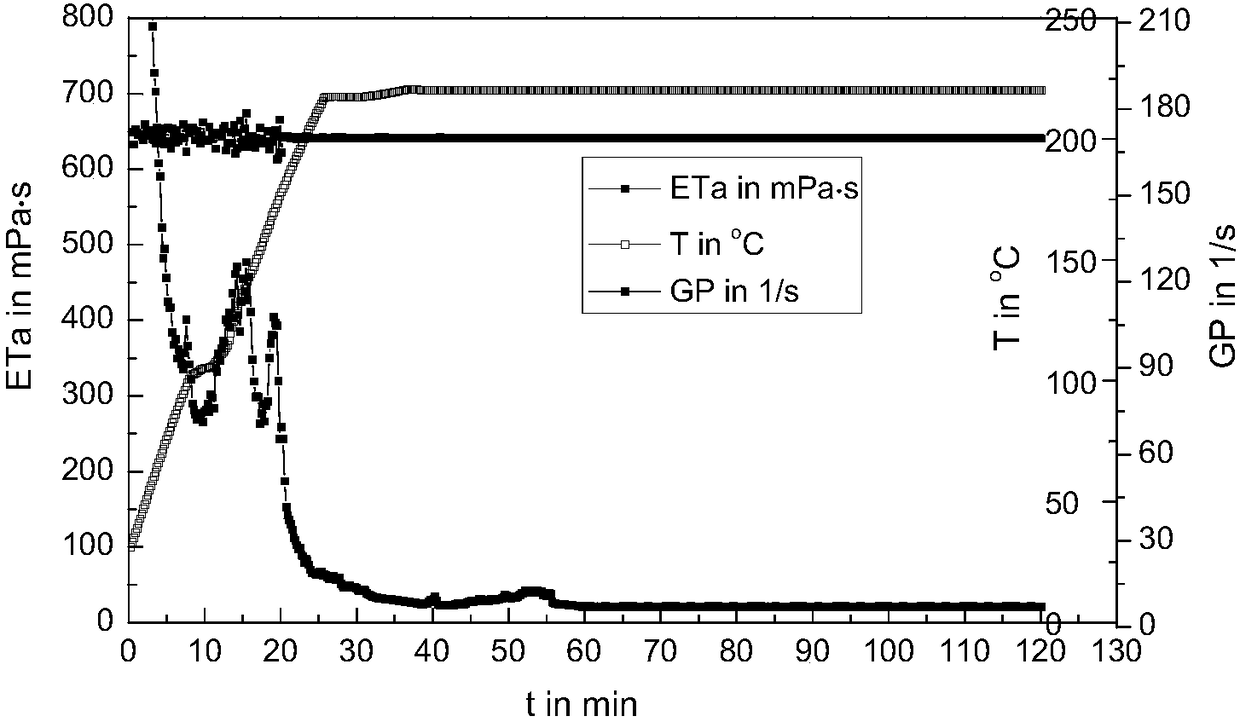

[0034] in the 170s -1 , The curve of the apparent viscosity of the high temperature resistant fracturing fluid system versus time was tested at 220°C, as shown in image 3 shown. From image 3 It can be seen that when the temperature rises, the apparent viscosity of the high-temperature resistant fracturing fluid drops sharply. When it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com