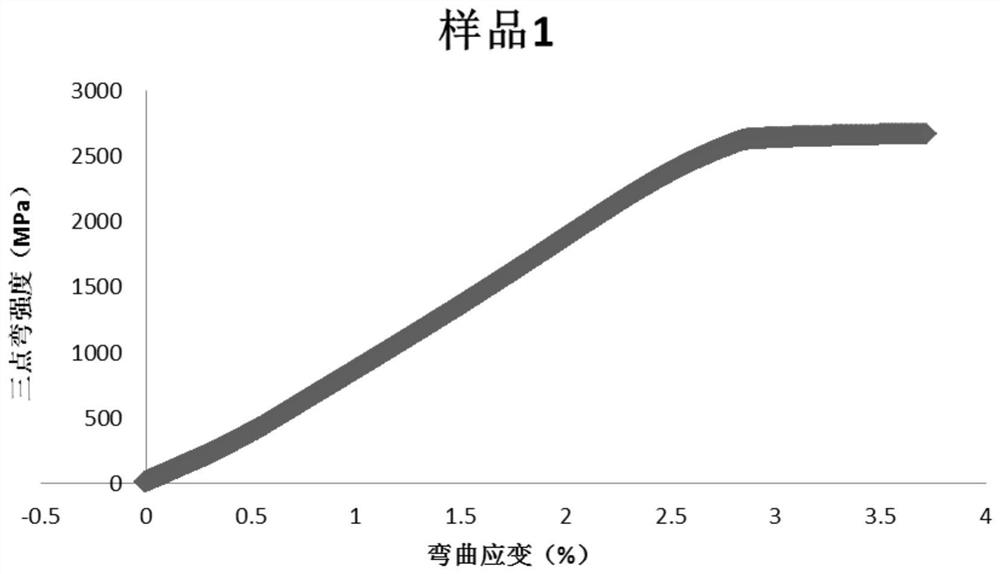

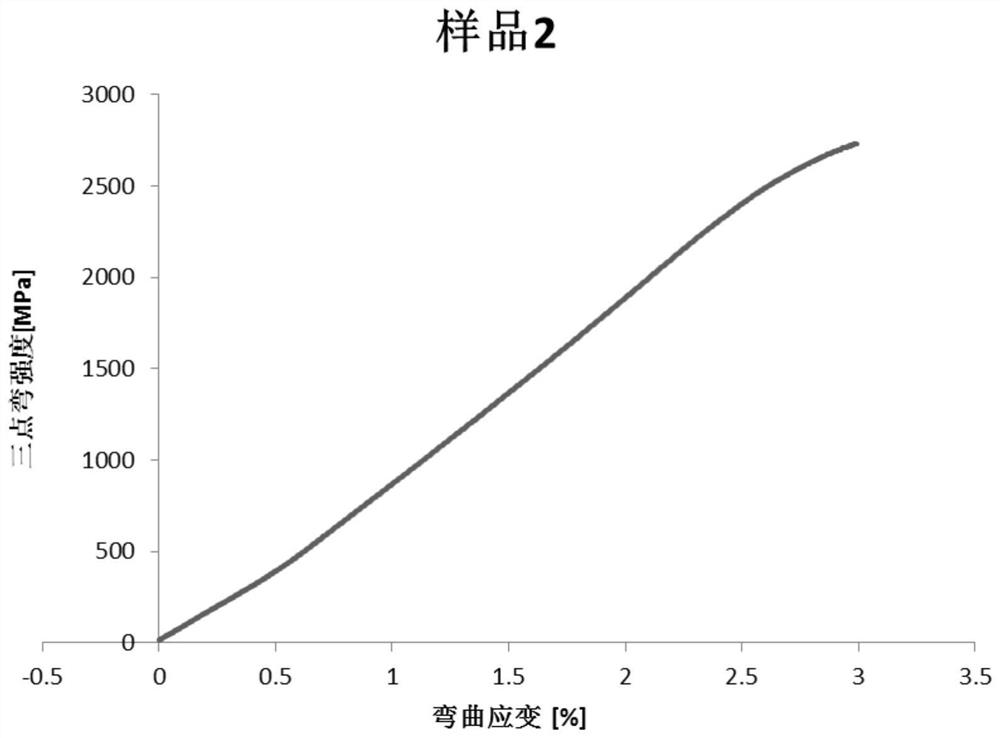

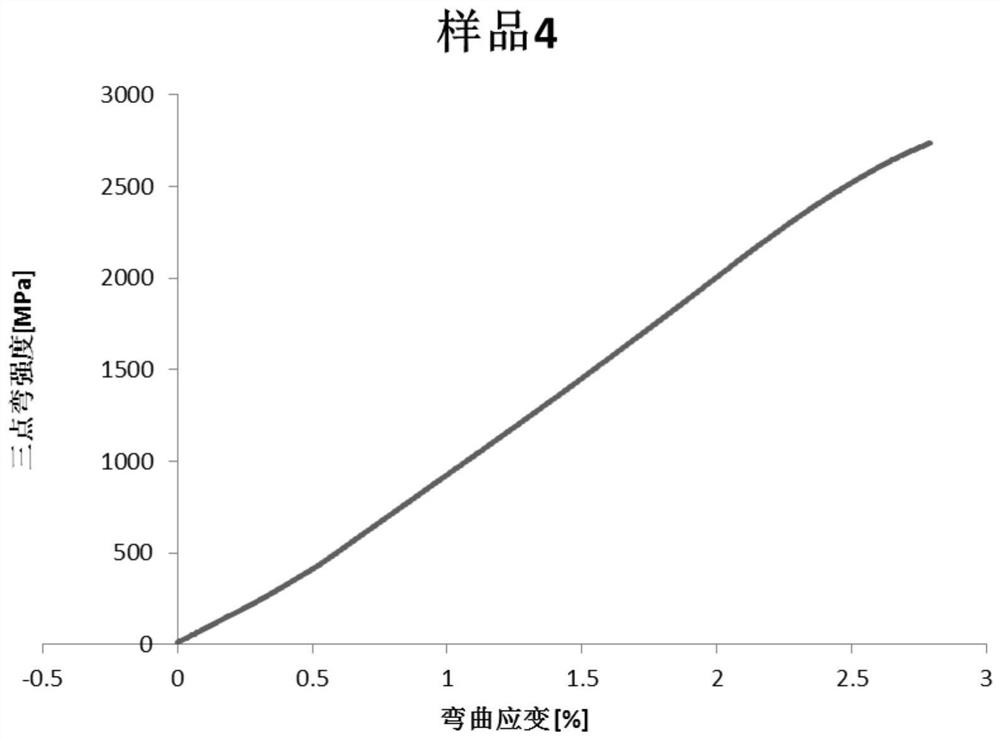

A high-toughness zirconium-based amorphous alloy material and its preparation method

A technology of zirconium-based amorphous alloy and amorphous alloy, which is applied in the field of high toughness and ultra-high strength zirconium-based amorphous alloy and its preparation, can solve the problems of low toughness and reliability test failure, and achieves the improvement of bending fracture strain. , The effect of improving glass forming ability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

[0048] The chemical composition of each Zr-based amorphous alloy is shown in Table 1.

[0049] The molar ratios of the elements of the Zr-based amorphous alloys in each embodiment are shown in Table 2.

[0050] The chemical composition of each element of table 1 embodiment

[0051]

[0052]

[0053] The molar ratio of each element of table 2 embodiment

[0054]

[0055] Alloy preparation method:

Embodiment 1

[0056] The preparation of embodiment 1 alloy

[0057] 1. According to the formula of chemical composition (Zr 0.9889 f 0.011 ) 55 (Cu 1-b-c-d Ni 0.1 al 0.22 Y 0.01 ) 40 Nb 3.5 Fe 1.5 , converted into atomic molar ratio is shown in the table below. Each formula needs to prepare 240g master alloy, one master alloy is prepared according to 60g, and a total of 4 master alloys need to be prepared. Convert to desired weighing weight according to atomic mass (total weight is 60 grams, 4 parts). Among them, the purity of zirconium is 99.4%, which is industrial-grade sponge zirconium, and the purity of other elements is 99.9%. The Hf element can also choose sponge zirconium with a certain Hf content, and the weight needs to be converted according to the atomic percentage.

[0058]

[0059] 2. Under the protection of argon, the ingot-shaped master alloy material is prepared by arc melting. The purpose of the whole process is to melt various elements into alloy materials....

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com