Metal interconnect structure and method of forming the same

A technology of metal interconnection structure and device structure, which is applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of metal interconnection failure, open circuit, thick insulating layer, etc., to ensure performance and prevent The effect of breaking the circuit and reducing the disc defect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

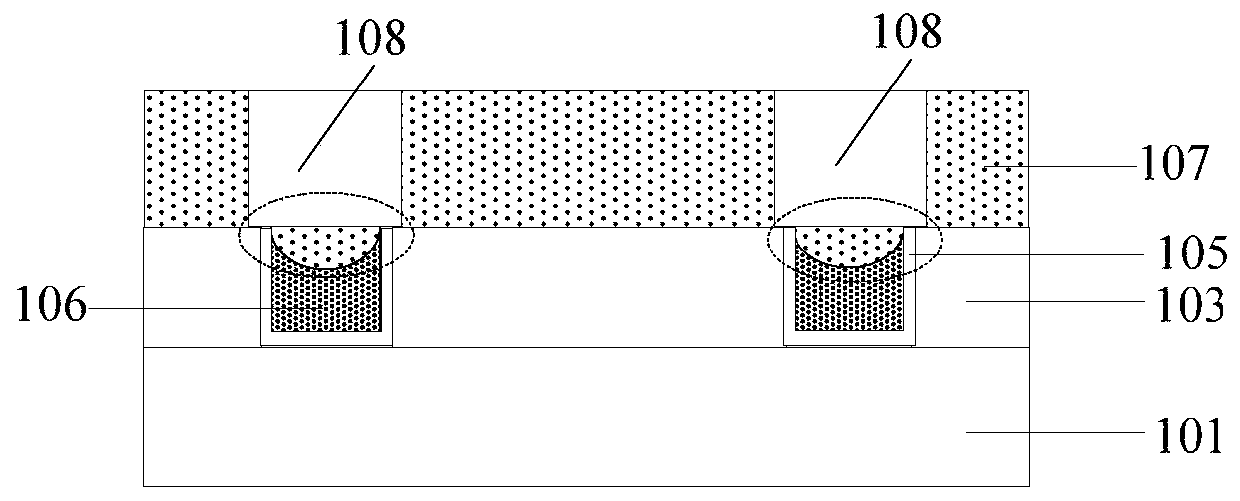

[0021] It can be seen from the background art that the metal interconnection structure with conductive plugs formed in the prior art has many open circuits, resulting in a problem of low yield of semiconductor devices. Now combine a metal interconnection structure to analyze the reasons for the poor electrical performance between metal interconnection structures:

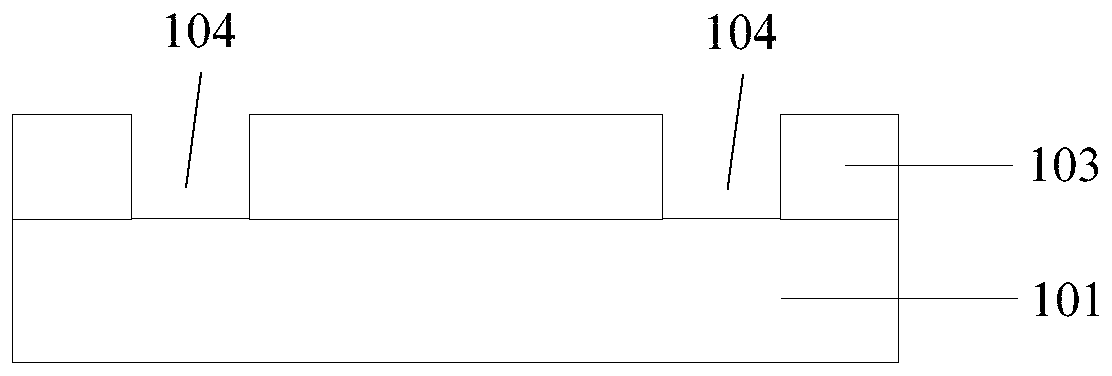

[0022] Figure 1 to Figure 3 A structural diagram corresponding to each step of the method for forming the metal interconnection structure is shown. Such as figure 1 As shown, a first insulating layer 103 is formed on the base layer 101 containing device structures such as driving circuits for isolation between film layers. The material of the first insulating layer 103 can be silicon oxide or silicon nitride; etching The first insulating layer 103 exposes the surface of the base layer 101 to form a contact hole 104 .

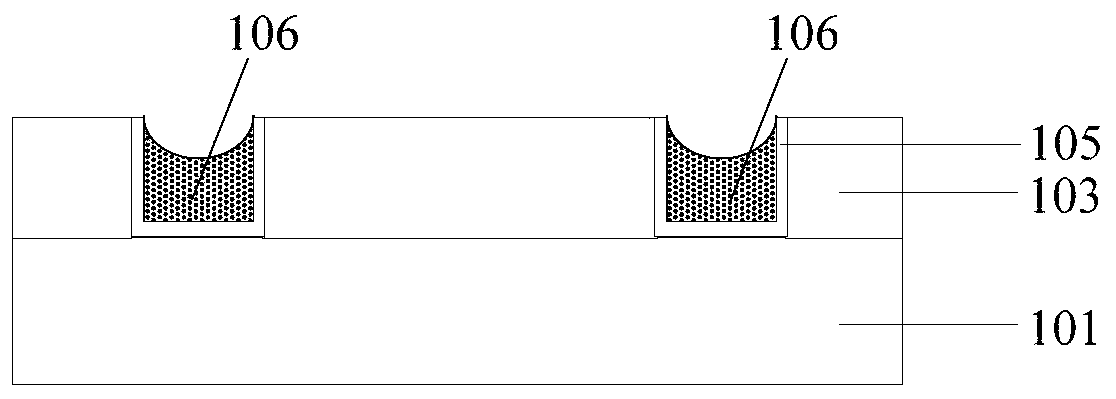

[0023] Such as figure 2 shown in figure 1 A barrier layer 105 is formed on the sidewall an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com