Low-ash lubricating oil composition

A technology of lubricating oil composition and ashless dispersant, which is applied in the direction of lubricating composition and petroleum industry to achieve good cleaning and dispersing properties, high temperature dispersibility, excellent viscosity-temperature characteristics, and excellent anti-wear effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

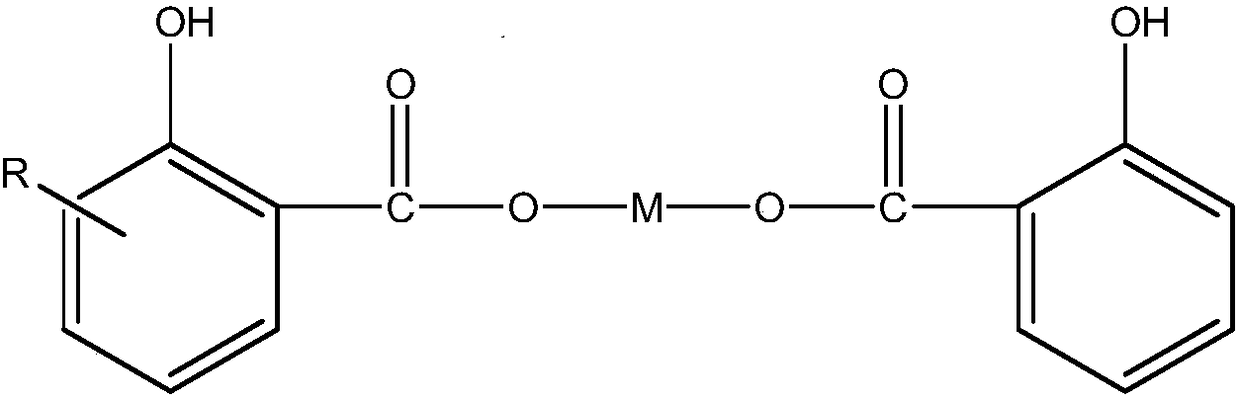

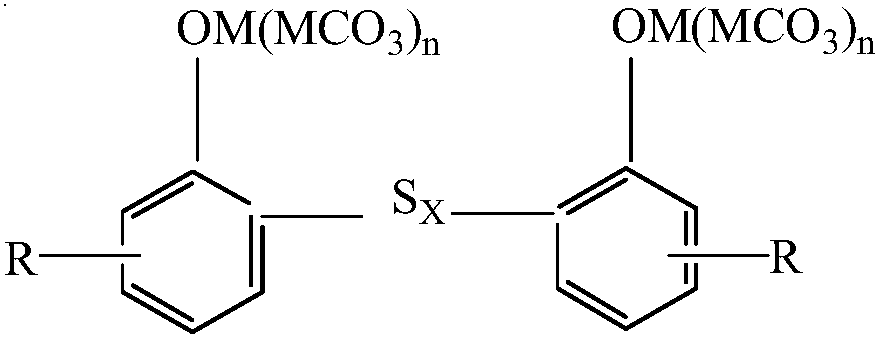

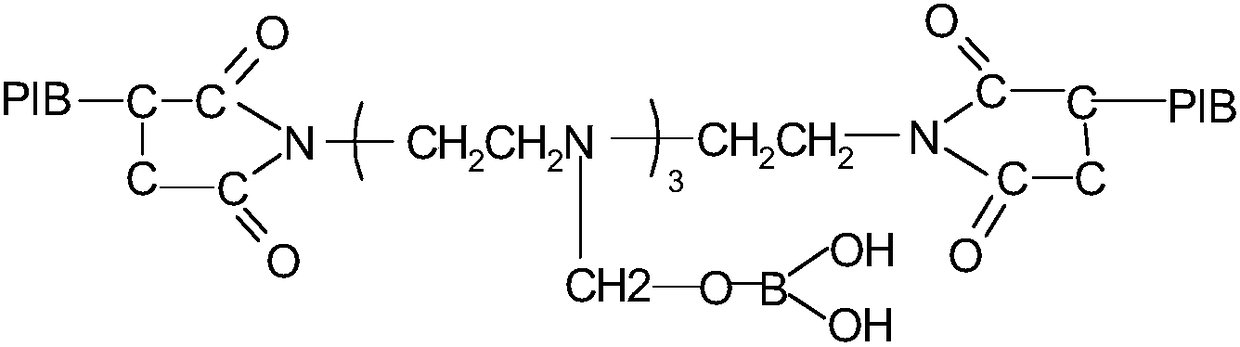

Method used

Image

Examples

Embodiment 1

[0079] Table 1 has provided the impact of different detergent formulation systems on CBT to further illustrate the present invention. In table 1, embodiment 11 and embodiment 12 are middle alkali value alkyl salicylate calcium and high alkali value sulfurized alkyl phenate calcium system, comparative example 11-comparative example 14 are other detergent systems, comparative example and embodiment all On the basis of meeting the requirements of sulfate ash and alkali value. Table 2 shows the results of the CBT test.

[0080] Table 1

[0081]

[0082] Table 2

[0083]

[0084]

[0085] As can be seen from Table 1 and Table 2, different detergent formulation systems have different influences on the anti-corrosion properties of oil products. What the embodiment adopted were medium-alkali value calcium alkyl salicylate and high-alkali value sulfurized alkylphenate calcium detergents. system, compared with other detergent systems, the CBT result of the oil is better, ind...

Embodiment 2

[0087] Table 3 shows the effect of specific corrosion inhibitors on CBT to further illustrate the invention. Examples 21 to 24 in Table 3 show the effects of adding different amounts of corrosion inhibitors on CBT. Table 4 shows the results of the CBT test.

[0088] table 3

[0089]

[0090] Table 4

[0091]

[0092] It can be seen from Table 3 and Table 4 that the addition of octadecylamine salt of isooctyl acid phosphate, which is usually used as an extreme pressure and antiwear agent, as a specific corrosion inhibitor can effectively improve the corrosion performance of oil products. Examples 22 and 23 When the addition amount of octadecylamine salt of isooctyl acid phosphate is 0.2 and 0.4, they all pass the CBT test. However, the addition amount increases again, and when it is 0.6, it cannot pass the CBT test, indicating that the addition amount of isooctyl acid phosphate octadecylamine salt cannot be too large.

Embodiment 3

[0094] Table 5 provides a series of experimental formulations to further illustrate the present invention. In Table 5, Comparative Example 31 is a commercial oil formulated with a commercially available compounding agent, which is currently the most widely used gas compounding agent in the world and is used as a standard for evaluating other oil products. Embodiment 31 and embodiment 32 are all-component 10W-40 low ash type gas engine lubricating oils of the present invention, and it contains middle base value alkyl salicylate, high base value sulfurized alkyl phenate, corrosion inhibitor, Borated dienyl succinimide ashless dispersant, polymer ashless dispersant, zinc dialkyldithiophosphate, phenolic auxiliary antioxidant and amine auxiliary antioxidant, etc. The components and contents are shown in Table 5, and the typical data thus obtained are listed in Table 6 and Table 7.

[0095] table 5

[0096]

[0097] Table 6

[0098]

[0099]

[0100] It can be seen from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com