Building fireproof and heat insulating hollow plate

A hollow and architectural technology, applied in fire protection, building components, heat preservation, etc., can solve the problems of poor fire and heat insulation performance of hollow boards, and achieve the effect of improving heat insulation and accelerating heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

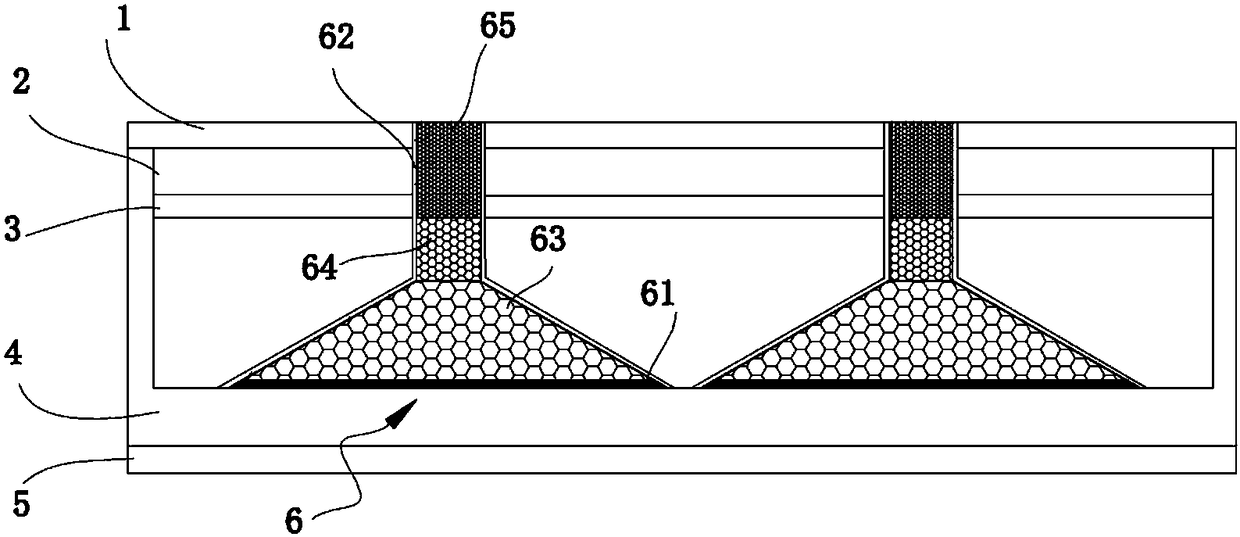

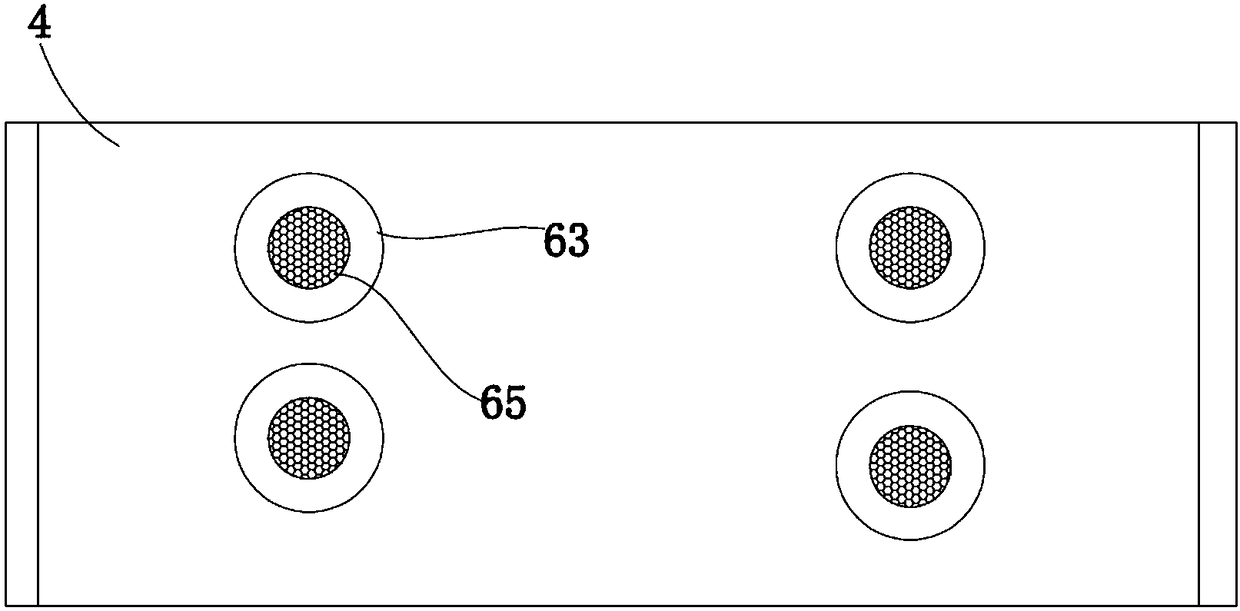

[0029] Please refer to the attached figure 1 And attached figure 2 , which discloses Embodiment 1 of the present invention, including an outer panel 1, a fireproof and heat insulating layer 2, a support surface 3, a cement tank 4, an inner panel 5, and a heat dissipation device 7.

[0030] A fire-proof and heat-insulating hollow board for a building. A closed hollow structure is formed by the upper and lower parallel outer panel 1, inner panel 5 and cement tank 4. The material of the outer panel 1 and inner panel 5 is phenolic foam insulation board, and the cement tank 4 is inlaid with Steel mesh to improve the strength and stability of the hollow board, the fireproof layer 2 is composed of 30 parts of aluminized polyimide, 35 parts of silicon nitride, 40 parts of epoxy / benzoxazine resin base and 5 parts of tri(2, 3-dichloropropyl) ester, and connected to the outer panel 1 and the support surface 3 in pairs, the heat sink 6 includes a copper metal heat conduction plate 61, a...

Embodiment 2

[0032] Please refer to the attached figure 1 , which discloses Embodiment 2 of the present invention, this embodiment is similar to Embodiment 1, the difference is that the fireproof layer 2 is made of 40 parts of aluminized polyimide, 45 parts of silicon nitride, and 60 parts of epoxy / benzoxazine resin base and 10 parts of tris(2,3-dichloropropyl) phosphate, the heat dissipation medium of the heat sink 6 is expanded perlite, the metal heat conduction plate 61 is an aluminum sheet, and the material of the shell 62 is silicon oxide with a gradual cross-sectional area The range is 10-48cm 2 , the incremental range of the bulk density of the first filling layer 63 is 0.7-1.9g / cm 3 , the increasing range of the bulk density of the second filling layer 64 is 2.0-2.5g / cm 3 , the bulk density of the third filling layer 65 increases in the range of 2.4-3.5g / cm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com