Method for production of Pixian bean paste

A production method, technology of watercress, applied in the field of watercress production in Pi County

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

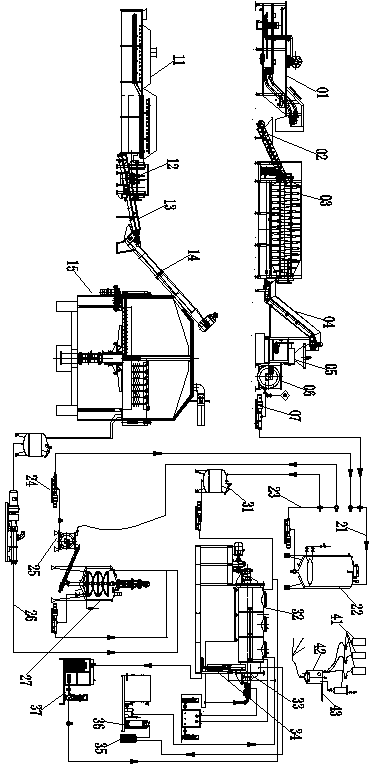

[0062] Such as figure 1 Shown, Pixian County watercress production method, described method comprises the following steps

[0063] A. Preparation of hot pepper embryos: select dried hot peppers that meet the standards, and then wash them in sequence in the washing machine 01, steam in the cooking machine 03, inject salt water into the pulverizer 05 and pulverize them, and send them to the mixer 06 after pulverization. Pepper germ delivery pump 07 on 06 is fed to main fermenter 22 by main fermenter feed pipe 21 for fermentation to obtain capsicum pepper embryos;

[0064] B. Preparation of broad bean paste flaps: input broad bean flaps into the blanching cooling device 11 for rinsing and cooling, and the cooled broad bean flaps are transported to the disc koji making device 15 through the delivery inoculation device while inoculating bacteria powder and mixing them. Douban making koji; after making koji by the disc koji making device, the feeding pipe 26 of the broad bean ferme...

Embodiment 2

[0068] On the basis of embodiment 1, the present embodiment provides a kind of better preparation process of capsicum pepper embryo, specifically as follows:

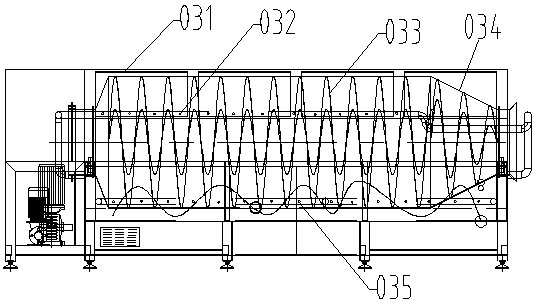

[0069] Such as figure 1 As shown, in step A, the cleaning machine 01 is connected to the cooking machine 03 through a screw hoist 02, and the top of the screw hoist 02 extends into the cooking machine 03; the cooking machine 03 is connected to the pulverizer 05 through a draining hoist 04 , the feed end of the drain hoist 04 is arranged below the discharge port of the cooking machine 03, and the discharge end is arranged above the feed port of the pulverizer 05; the discharge port of the pulverizer 05 is connected to the mixer 06 On the feed port, one end of the pepper embryo delivery pump 07 is connected to the discharge port of the mixer 07, and one end is connected to the feed pipe 21 of the main fermentation tank; as figure 2 As shown, the cooking machine 03 includes a cover body 031, a tumbler 034 arranged in the...

Embodiment 3

[0071] On the basis of Embodiment 1, the present embodiment provides a system and a koji-making process of a better broad bean koji making process, as follows:

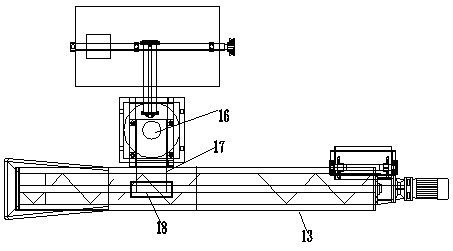

[0072] In step B, as in figure 1 , image 3 , Figure 4 As shown, the conveying inoculation device includes a conveying mechanism and an inoculating device 12, and the conveying mechanism includes an auger conveyor 13 and a scraper conveyor 14, and the conveying mechanism is arranged between the drift cooling device 11 and the disc koji making device Between 15, the auger conveyor 13 is connected with the drift cooling device 11, and the scraper conveyor 14 is connected with the disc koji making device 15; the inoculation device 12 includes a vibrating mechanism 19 and a casing 17, and the The vibration mechanism 19 drives the box body 17 to vibrate. The top of the box body 17 is provided with a bacteria powder inlet 16, and any side wall opening of the box body 17 forms a bacteria powder outlet 18. The box body 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com