Plant probiotic fermented Zaosu pear pulp and processing method thereof

A technology of plant probiotics and Lactobacillus plantarum, applied in the direction of Lactobacillus, food science, bifidobacterium, etc., can solve the problems of the backlog of Zaosu pears, achieve long aftertaste, realize rational utilization, and increase immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

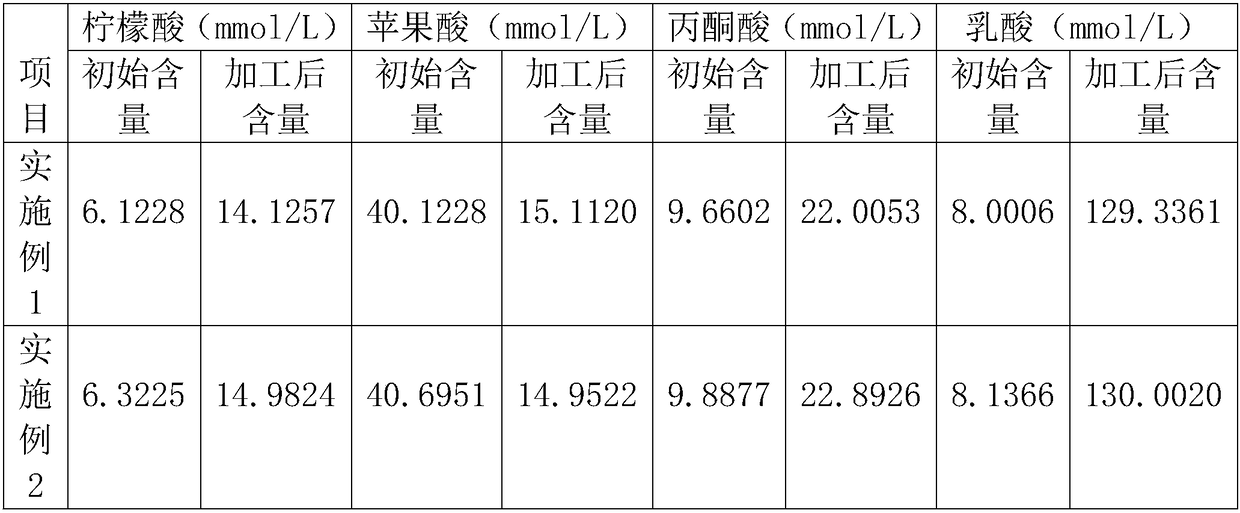

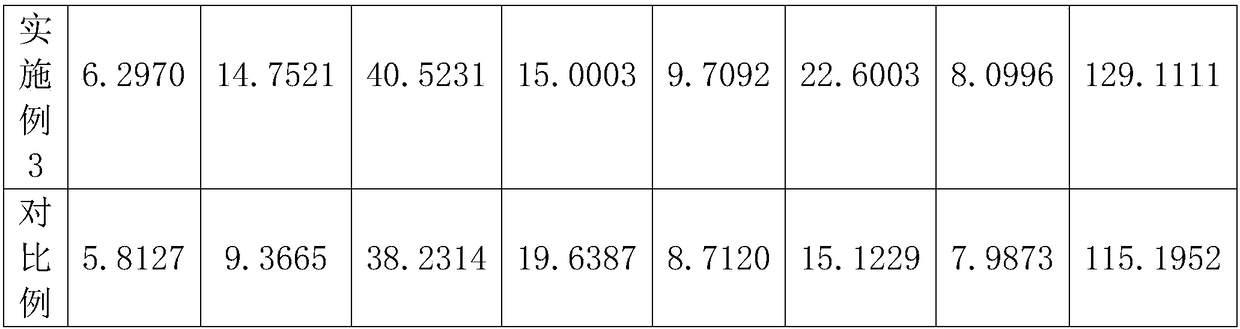

Embodiment 1

[0020] A plant probiotic fermented Zaosu pear pulp, which is composed of the following raw materials in parts by weight: 47 parts of Zaosu pear, 44 parts of carrot, 34 parts of bran, 31 parts of Radix Ophiopogon japonicus, 27 parts of nutmeg, 27 parts of Eucommia, Smilax tuckahoe 22 parts, 20 parts of emblica, 9 parts of white sugar, 7 parts of Lactobacillus plantarum, 6 parts of Lactobacillus acidophilus, 5.4 parts of Lactobacillus casei, 4.6 parts of Bifidobacterium.

[0021] The processing method of described plant probiotics fermented early crisp pear pulp, comprises the steps:

[0022] 1) The Zaosu pears are roasted after being cut into pieces, air-dried, and seeded. The initial roasting temperature is set at 65°C, and the Zaosu pears are roasted in three temperature stages. The temperature was raised at a speed of 5°C / min, and then raised to 120°C after 9 minutes; the second stage was heated to 150°C at a speed of 1.2°C / min, and the processing time was 25 minutes; the th...

Embodiment 2

[0027] A plant probiotic fermented Zaosu pear pulp, which is composed of the following raw materials in parts by weight: 57 parts of Zaosu pear, 53 parts of carrot, 45 parts of bran, 42 parts of Radix Ophiopogon japonicus, 37 parts of nutmeg, 37 parts of Eucommia ulmoides, 32.5 parts of Smilax tuckahoe 28.5 parts of emblica, 11 parts of white sugar, 8.8 parts of Lactobacillus plantarum, 7.8 parts of Lactobacillus acidophilus, 7.2 parts of Lactobacillus casei, and 5.8 parts of Bifidobacterium.

[0028] The processing method of described plant probiotics fermented early crisp pear pulp, comprises the steps:

[0029] 1) The Zaosu pears are roasted after being cut into pieces, air-dried, and seeded. The initial roasting temperature is set at 65°C, and the Zaosu pears are roasted in three temperature stages. The temperature was raised at a speed of 5°C / min, and then raised to 120°C after 9 minutes; the second stage was heated to 150°C at a speed of 1.2°C / min, and the processing tim...

Embodiment 3

[0034] A plant probiotic fermented Zaosu pear pulp, which is composed of the following raw materials in parts by weight: 67 parts of Zaosu pear, 62 parts of carrot, 56 parts of bran, 53 parts of Radix Ophiopogon japonicus, 47 parts of nutmeg, 47 parts of Eucommia, Smilax tuckahoe 43 parts, 37 parts of amla seed, 13 parts of white sugar, 10.5 parts of Lactobacillus plantarum, 9.5 parts of Lactobacillus acidophilus, 9 parts of Lactobacillus casei, 7 parts of Bifidobacterium.

[0035] The processing method of described plant probiotics fermented early crisp pear pulp, comprises the steps:

[0036] 1) The Zaosu pears are roasted after being cut into pieces, air-dried, and seeded. The initial roasting temperature is set at 65°C, and the Zaosu pears are roasted in three temperature stages. The temperature was raised at a speed of 5°C / min, and then raised to 120°C after 9 minutes; the second stage was heated to 150°C at a speed of 1.2°C / min, and the processing time was 25 minutes; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com