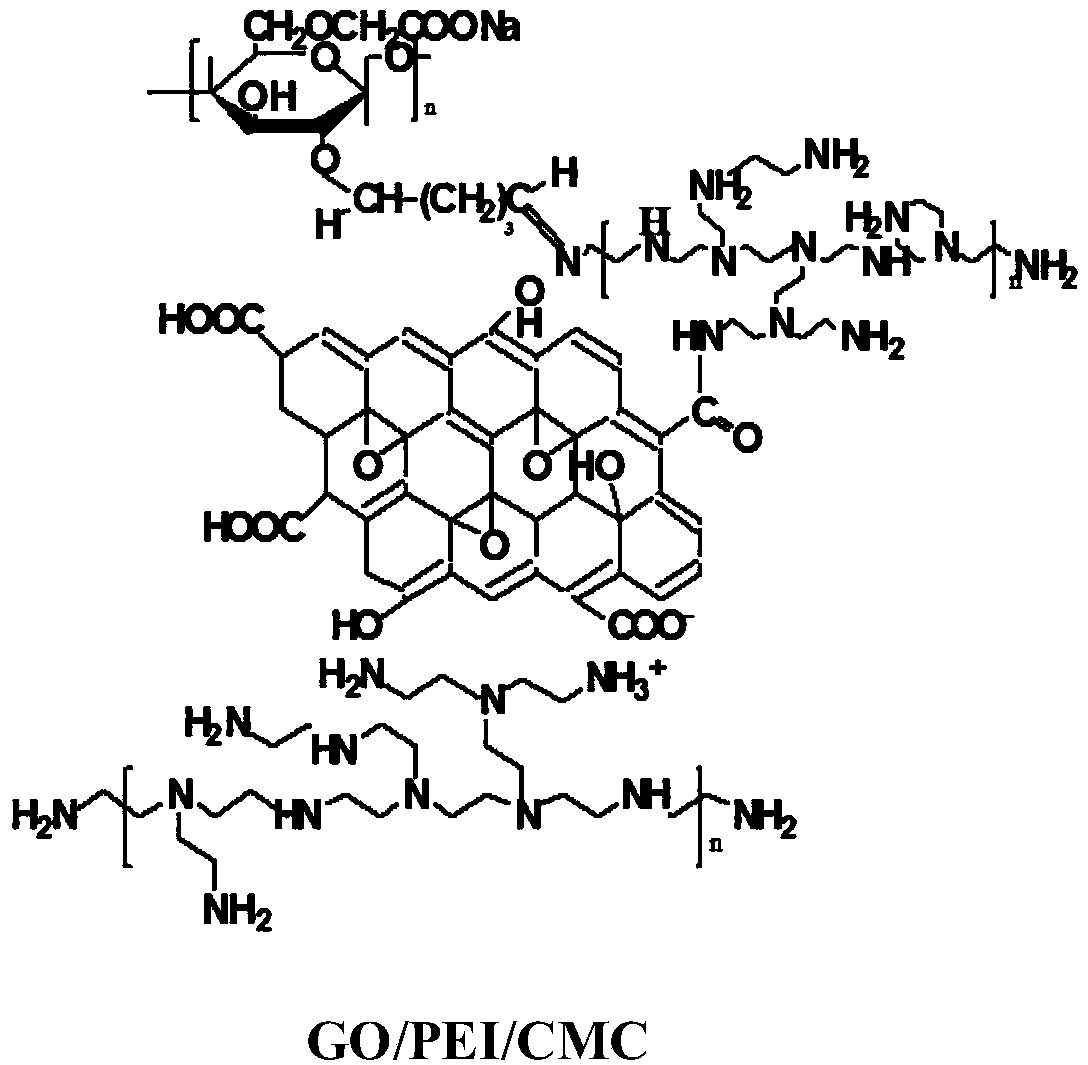

Preparation method of three-dimensional graphene oxide/polyethyleneimine/carboxymethyl cellulose composite material

A technology of carboxymethyl cellulose and sodium carboxymethyl cellulose is applied in the field of preparation of three-dimensional graphene oxide/polyethyleneimine/carboxymethyl cellulose composite material, which can solve the problem of low adsorption capacity and poor reusability , the problem of high cost, to achieve the effect of simple preparation method, low cost, and improved adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

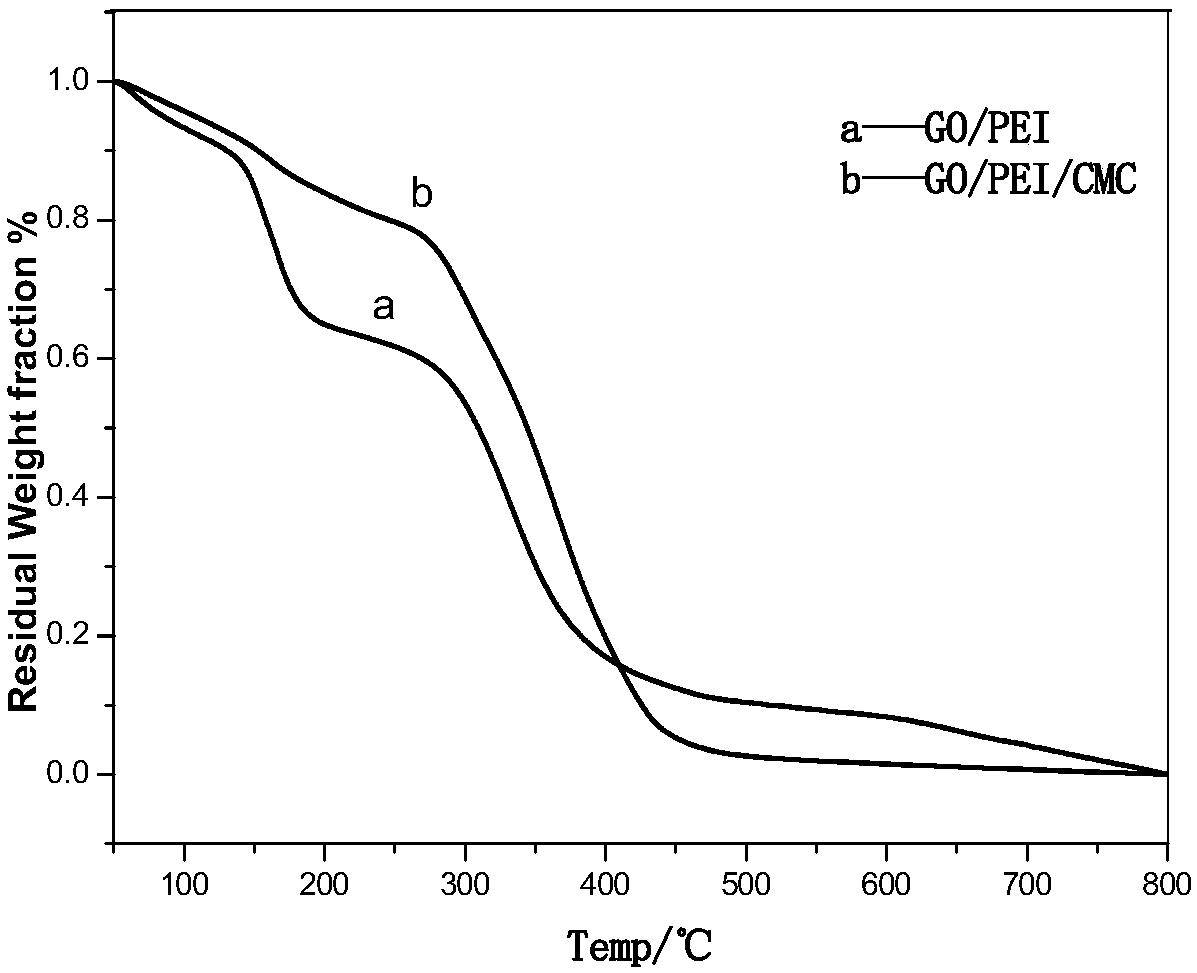

[0025] (1) Preparation of graphene oxide / polyethyleneimine: place 0.2 g of graphite oxide in deionized water to obtain a graphene oxide dispersion by ultrasonication, adjust the pH of the GO dispersion to 8.0 with 0.1 M NaOH, and then add poly The quality of ethyleneimine is 0.2 g of polyethyleneimine solution equal to the volume of GO, ultrasonic for 1 min, and reacted at room temperature for 20 h to obtain graphene oxide / polyethyleneimine composite liquid.

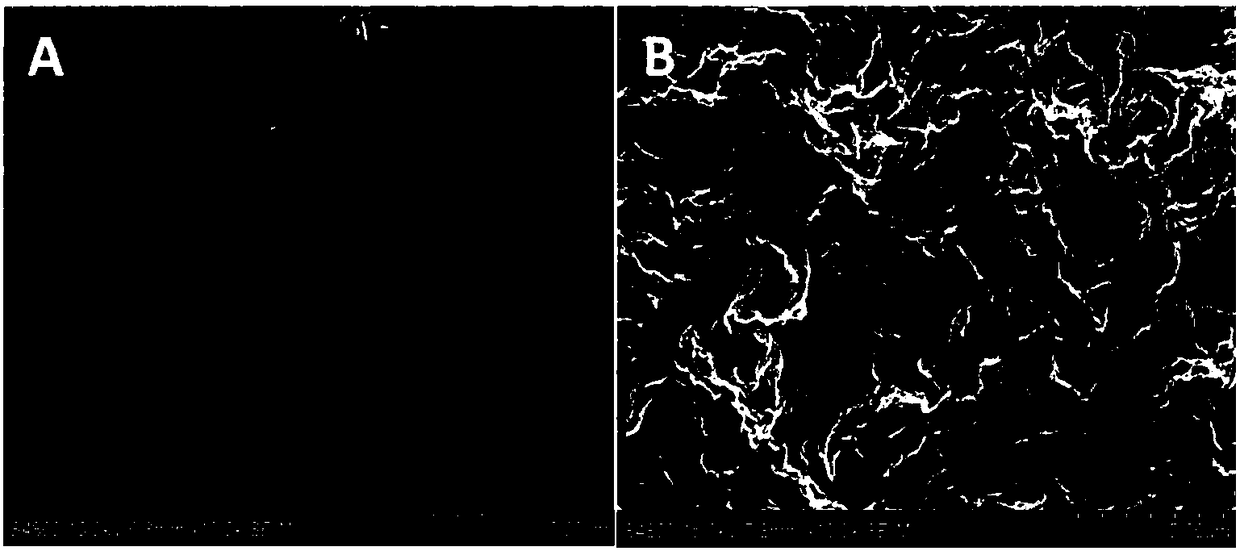

[0026] (2) Preparation of graphene oxide / polyethyleneimine / carboxymethyl cellulose: adding the graphene oxide / polyethyleneimine composite solution to 0.1 g of sodium carboxymethyl cellulose equal to the concentration of GO In the sodium carboxymethyl cellulose solution, stir rapidly for 30 minutes, then slowly add glutaraldehyde dropwise at room temperature at a stirring speed of 800 rpm, after the addition is completed, continue to react for 4 hours at a stirring speed of 600 rpm, finally, wash and dry to obtain a three-...

Embodiment 2

[0029] (1) Preparation of graphene oxide / polyethyleneimine: place 0.2 g of graphite oxide in deionized water to obtain a graphene oxide dispersion by ultrasonication, adjust the pH of the GO dispersion to 8.0 with 0.1 M NaOH, and then add poly The quality of ethyleneimine is 0.4g polyethyleneimine solution equal to the volume of GO, ultrasonic for 1min, and reacted at room temperature for 20h to obtain graphene oxide / polyethyleneimine composite liquid.

[0030] (2) Preparation of graphene oxide / polyethyleneimine / carboxymethyl cellulose: adding the graphene oxide / polyethyleneimine composite solution to 0.1 g of sodium carboxymethyl cellulose equal to the concentration of GO In the sodium carboxymethyl cellulose solution, stir rapidly for 30 minutes, then slowly add glutaraldehyde dropwise at room temperature with a stirring speed of 1000 rpm, after the addition is completed, continue to react for 4 hours at a stirring speed of 500 rpm, finally, wash and dry to obtain a three-dim...

Embodiment 3

[0033] (1) Preparation of graphene oxide / polyethyleneimine: place 0.2 g of graphite oxide in deionized water to obtain a graphene oxide dispersion by ultrasonication, adjust the pH of the GO dispersion to 8.0 with 0.1 M NaOH, and then add poly The quality of ethyleneimine is 0.6 g of polyethyleneimine solution equal to the volume of GO, ultrasonic for 1 min, and reacted at room temperature for 24 h to obtain graphene oxide / polyethyleneimine composite liquid.

[0034] (2) Preparation of graphene oxide / polyethyleneimine / carboxymethyl cellulose: adding the graphene oxide / polyethyleneimine composite solution to 0.1 g of sodium carboxymethyl cellulose equal to the concentration of GO In the sodium carboxymethyl cellulose solution, stir rapidly for 30 minutes, then slowly add glutaraldehyde dropwise at room temperature with a stirring speed of 1000 rpm, after the addition is completed, continue to react for 4 hours at a stirring speed of 500 rpm, finally, wash and dry to obtain a thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com